Full-automatic assembly device of temperature controller

An assembly device, fully automatic technology, applied in electrical components, electrical switches, circuits, etc., can solve the problems of labor shortage, high labor costs, low output, etc., to improve product quality and production efficiency, improve accuracy and reliability. , the effect of low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings will be used for a detailed description, as follows:

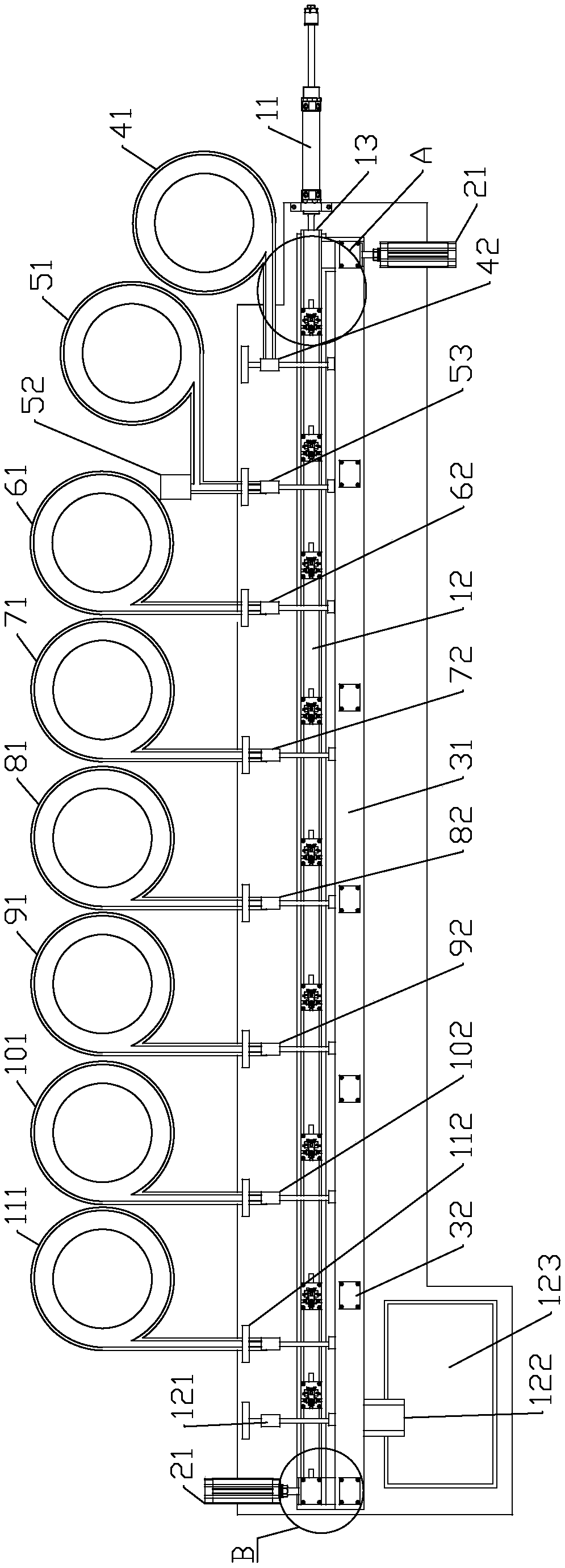

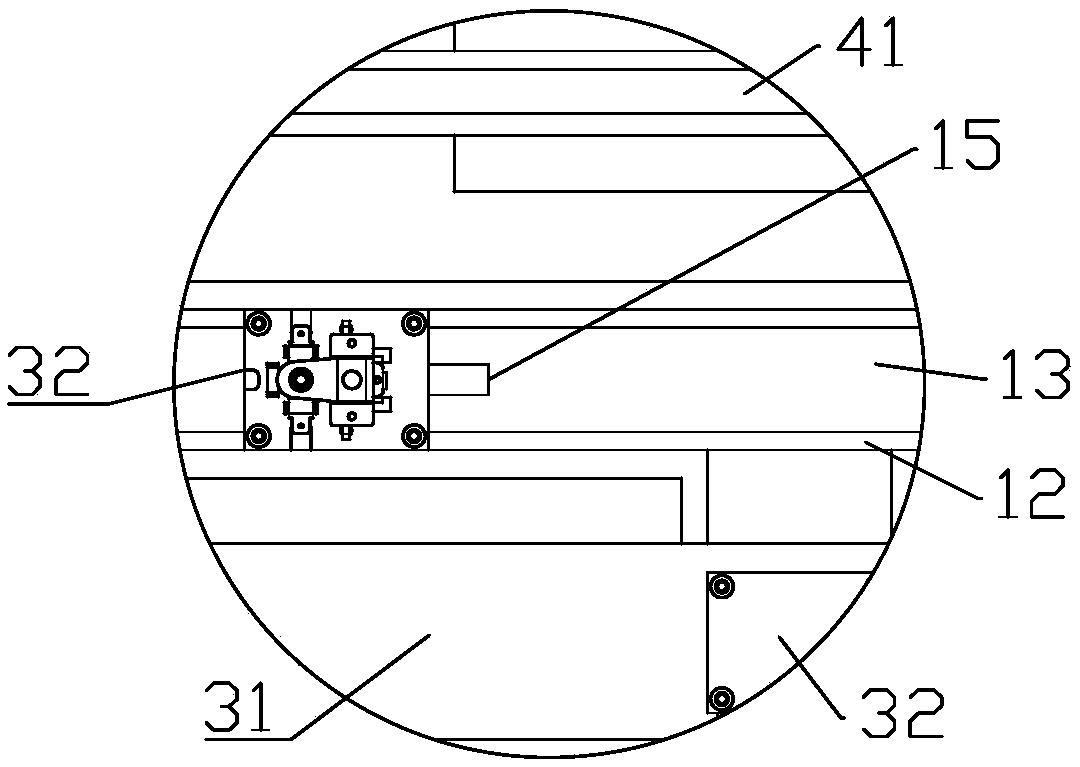

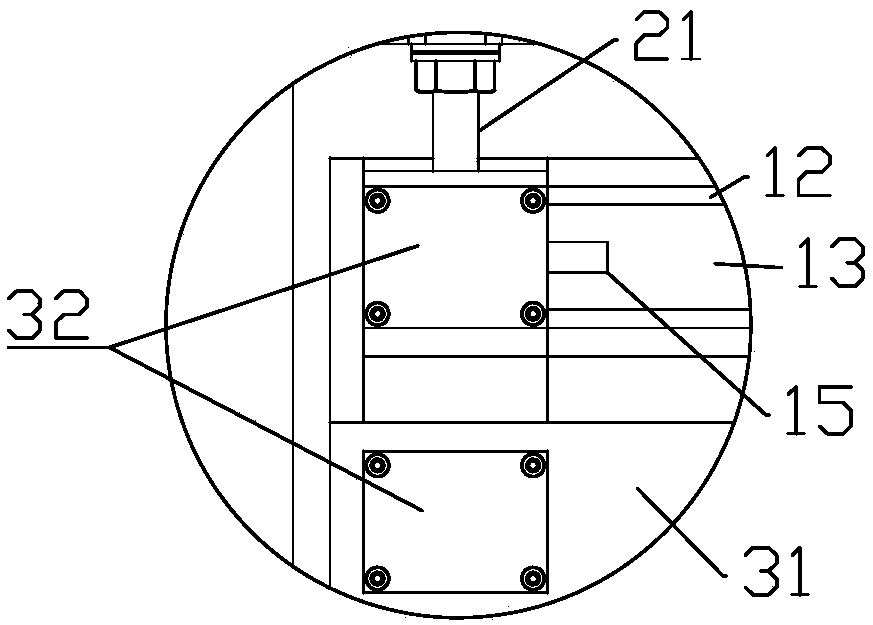

[0021] Such as Figure 1 to Figure 5 As shown, a fully automatic assembly device for a temperature controller, as an improvement of the present invention, includes a dislocation station, a pushing station, a bottom mold station, a rivet station, a bimetal sheet station, a porcelain tube station, Porcelain ring station, terminal post station, shrapnel station, contact sheet station, bracket station, finished product station and control unit, rivet station, bimetal sheet station, porcelain tube station, porcelain ring station, Terminal station, shrapnel station, contact piece station, bracket station, and finished product station are all equipped with incoming material detection sensors. The misalignment station includes the misalig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com