Substrate support module for excimer laser annealing equipment

A technology of excimer laser and annealing device, which is applied in the quasi field, can solve the problems of substrate quality reduction, low productivity, and uneven heat treatment uniformity, and achieve the effect of minimizing the generation of bubbles and minimizing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

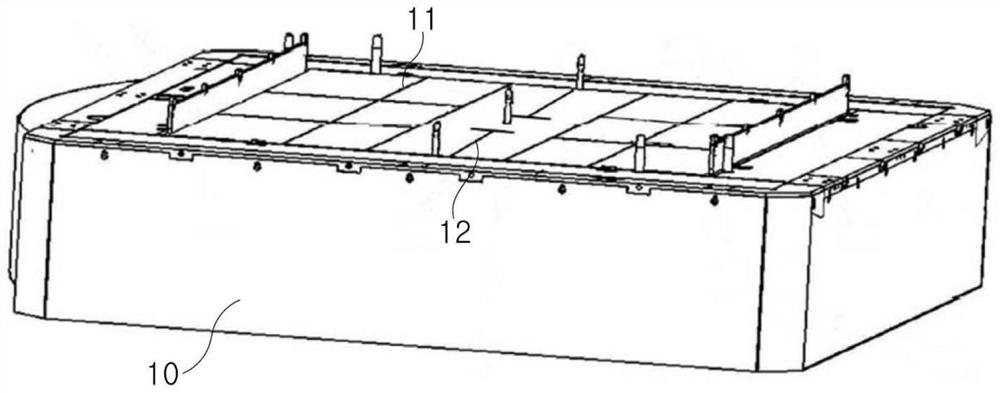

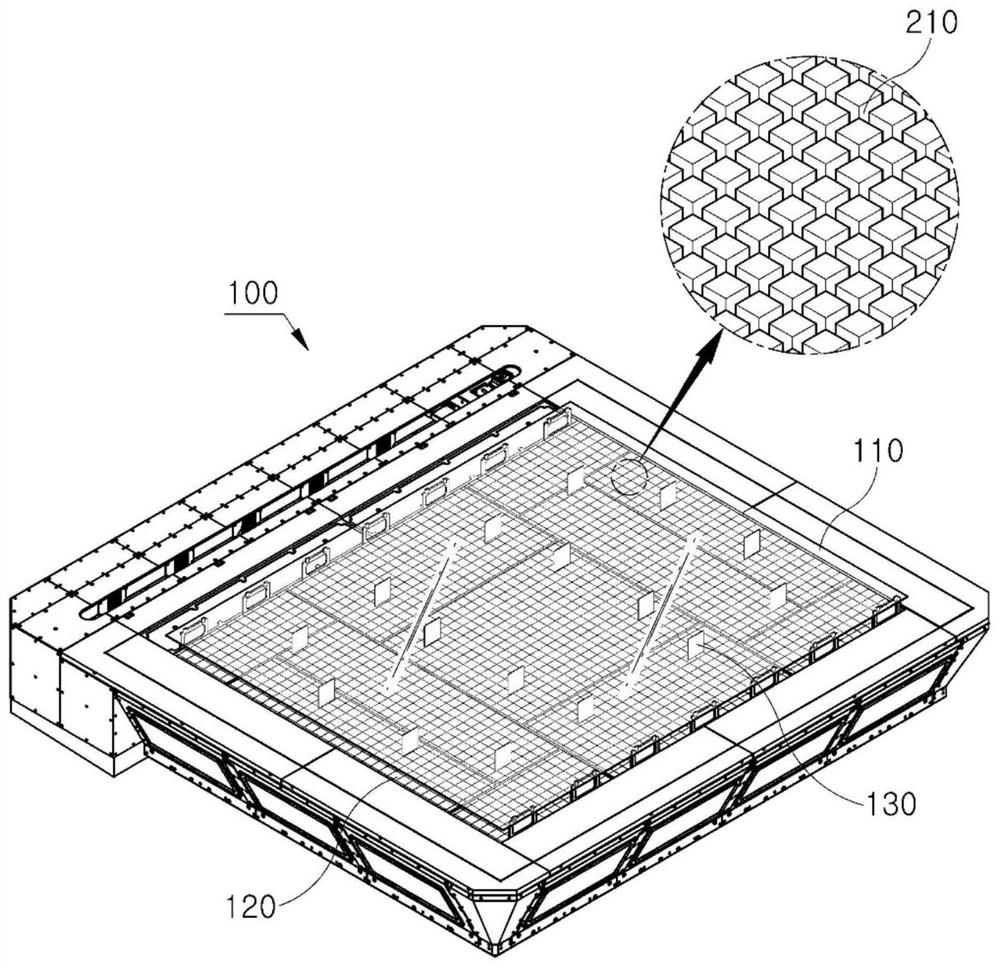

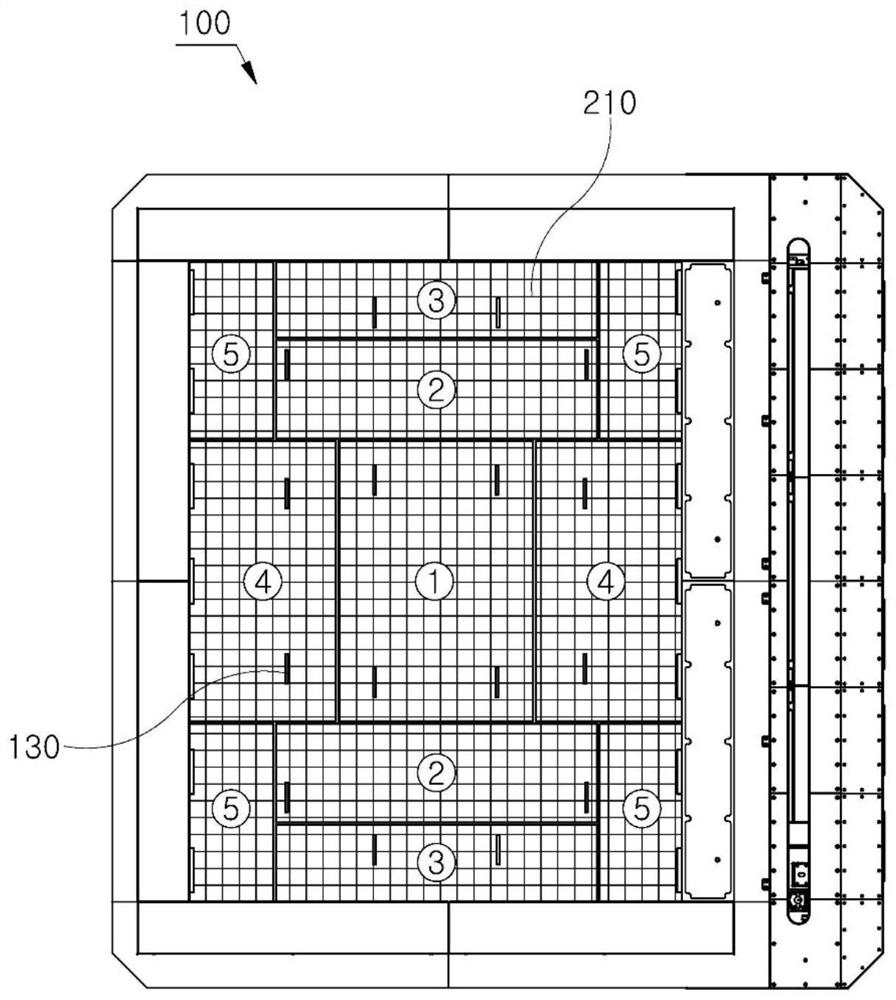

[0035] The present invention relates to a substrate supporting module for an excimer laser annealing device, which divides a workbench for placing a substrate into predetermined areas to form independent vacuum suction areas, so that vacuum suction is performed sequentially from the central part of the workbench, so that the above-mentioned substrate The central part of the substrate is sequentially in contact with the above-mentioned table, thereby preventing the generation of air bubbles between the substrate and the table, and minimizing the bending phenomenon of the substrate.

[0036] In addition, a grid-shaped pattern is formed on the upper part of the workbench to minimize the contact area between the workbench and the substrate, and to make the flow of air smooth to minimize the temperature gradient of the substrate, thereby minimizing the occurrence of spots on the substrate , so that high-quality substrates can be obtained.

[0037] Hereinafter, the present invention w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com