Blockage-proof grain processing device for flour processing

A processing device and anti-clogging technology, which is applied in the direction of grain processing, etc., can solve the problems of grain and husk clogging, single function, and affecting the yield of gluten particles in the separation effect, so as to prevent clogging and improve the smooth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

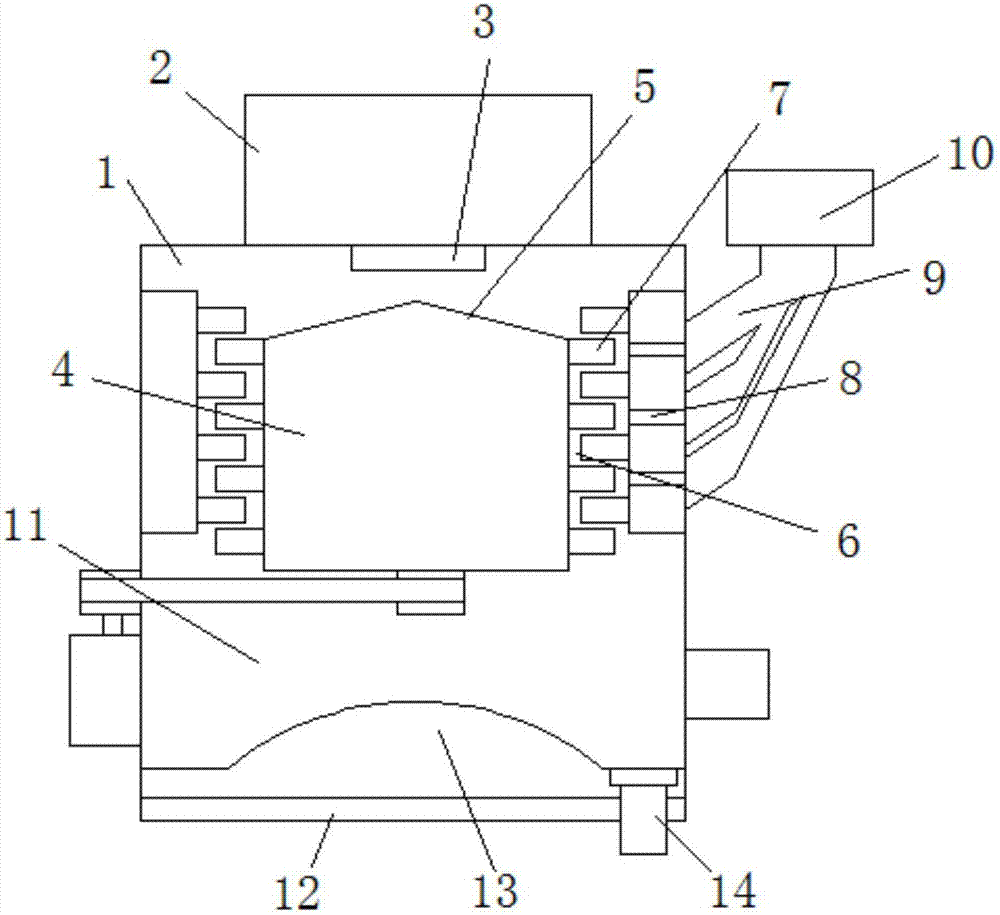

[0011] Referring to the accompanying drawings, a kind of anti-clogging type flour processing grain processing device includes a cabinet 1, the top of the cabinet 1 is provided with a feed bin 2, and the bottom of the feed bin 2 is provided with a feeding port 3, and the feeding port 3 is provided with a grinding cylinder 4, the top of the grinding cylinder 4 is provided with a conical top 5, the two sides of the conical top 5 are provided with a grinding gap 6, and on the outer wall of the grinding cylinder 4 There are multiple partitions 7, and each partition 7 is staggered from the partition on the side wall of the cabinet 1, and the bottom of the partition on the side wall of the cabinet 1 is provided with a blast hole 8, and the blast hole 8 It is connected to an external air blast pipe 9, the air blast pipe 9 is connected to a blower 10, and a peeling chamber 11 is provided below the grinding cylinder 4.

[0012] The bottom of the cabinet 1 is provided with a vibrating sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com