Centrifugal casting device for copper sleeve

A centrifugal casting and copper sleeve technology, applied in the field of mechanical component processing devices, can solve the problem of uneven crystallization of copper sleeves, and achieve the effects of avoiding uneven crystallization, saving energy and saving electric energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below by specific embodiments:

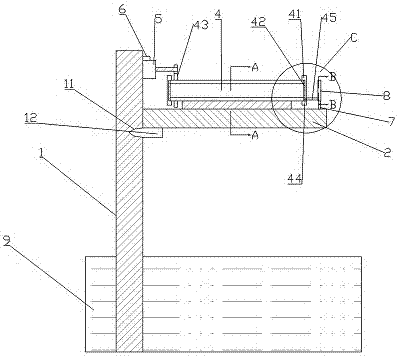

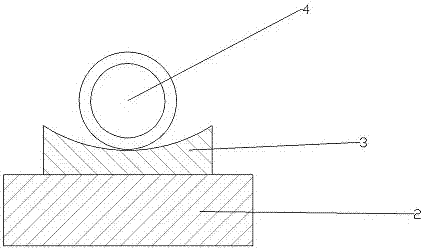

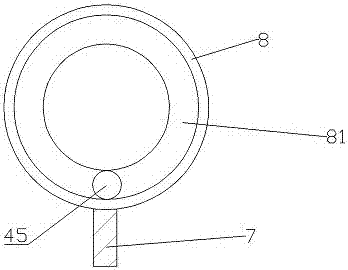

[0028] The reference signs in the accompanying drawings of the specification include: frame 1, limit hole 11, limit block 12, support platform 2, cylinder support 3, casting cylinder 4, end cap 41, asbestos pad 42, flywheel 43, cooling pipe 44, cooling tank 45, motor 5, power supply 6, support 7, limit plate 8, annular chute 81, water tank 9.

[0029] like figure 1 As shown, the centrifugal casting device of the copper sleeve includes a water tank 9, which is filled with water, and a frame 1 is arranged in the water tank 9, and the frame 1 is longitudinally slid to be connected with a support platform 2, and the right side of the upper part of the frame 1 A limit hole 11 is provided, and the limit hole 11 is provided with a matching limit block 12. A motor 5 is arranged above the limit hole 11 on the frame 1, and a power supply 6 is connected to the motor 5.

[0030] The upper surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com