Dyeing machine cloth outlet squeezing water recovery device and a working method thereof

A recovery device and dyeing machine technology, which is applied to the configuration of textile material equipment and the removal of liquid/gas/steam with squeeze rollers, can solve the problems of splashing, waste, and unfavorable utilization of dyeing liquid, and achieve high recycling efficiency and reduction Small waste, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

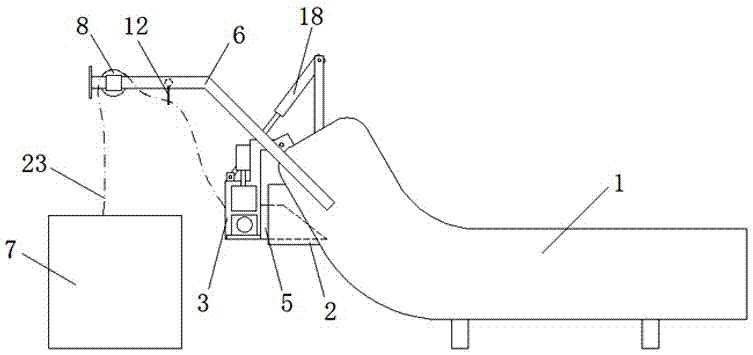

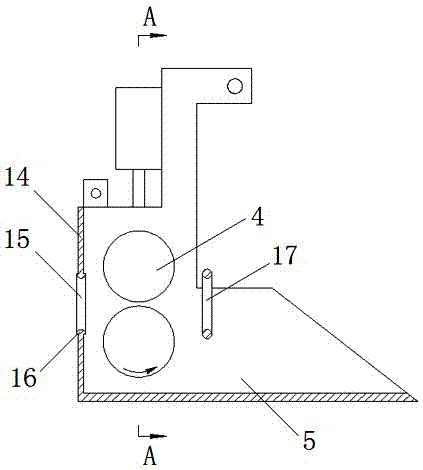

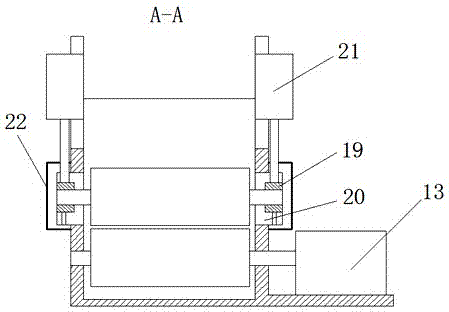

[0017] like Figure 1~4 As shown, a dyeing machine outlet water recovery device includes a dyeing vat 1 with a cloth inlet and outlet 2 at the front end, and a frame 3 that can swing up and down is hinged on the dyeing vat above the cloth inlet and outlet 2. A pair of rollers 4 are arranged on the body, and the bottom of the frame body 3 is provided with a liquid guide plate 5 that can extend into the cloth opening 2 when the hem of the frame body is finished. 3 The bottom hem makes the liquid guide plate 5 on the frame extend into the cloth opening, pulls out the cloth and passes it through the middle of the two rolls 4, squeezes out the dye solution sucked in the cloth by the two rolls and flows back through the liquid guide plate 5 Dyeing vat, so that most of the dye liquor can be recovered, avoiding subsequent recovery operations.

[0018] In this embodiment, a cloth outlet frame 6 is arranged obliquely above the frame body 3, and a cloth receiving frame 7 is arranged bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com