Inner-cylinder axial-flow integrated pre-fabricated pumping station

An inner cylindrical shaft and axial flow technology, applied in waterway systems, drainage structures, water supply devices, etc., can solve the problems of high operation and maintenance costs, large floor space, and long construction period, saving equipment investment and occupation. The effect of increasing land area and processing scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Further description will be made below in conjunction with drawings and embodiments.

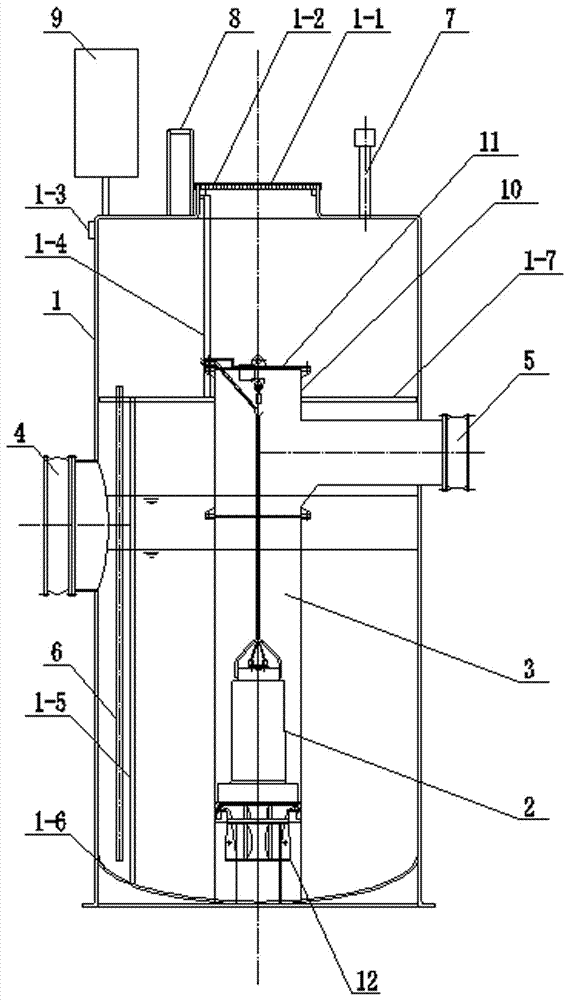

[0018] figure 1 Shown: an inner cylinder axial flow integrated prefabricated pumping station includes a cylinder body 1, a submersible axial flow sewage pump 2, an exhaust pipe 7 and a control system 9, the cylinder body 1 is provided with an exhaust pipe 7, and the cylinder body There are lifting lugs 1-3 on the side wall, water inlet 4 is opened on the side wall of the middle part of the cylinder body 1, the bottom of the cylinder body is a bottom spherical structure 1-6 with a low center and a high periphery, and the lower part of the shaft 3 is coaxially installed on the cylinder body 1 and the lower parts of the two are connected, the upper part of the shaft 3 is connected to the lower port of the tee joint 10, the side port of the tee joint 10 is connected to the water outlet 5 protruding from the cylinder, the water outlet is higher than the water inlet, and the upper port of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com