Retrofit lamp

A light source module and heat sink technology, which is applied in the direction of lighting devices, the use of semiconductor lamps, and components of lighting devices, can solve the problems of high component and installation costs, reduce insulation distances, etc., and achieve small installation costs and long insulation distances , Improve the effect of ESD compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

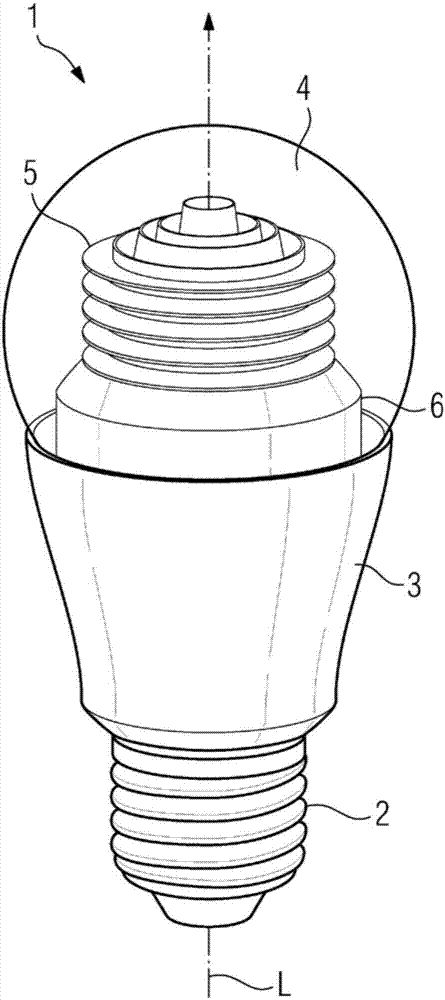

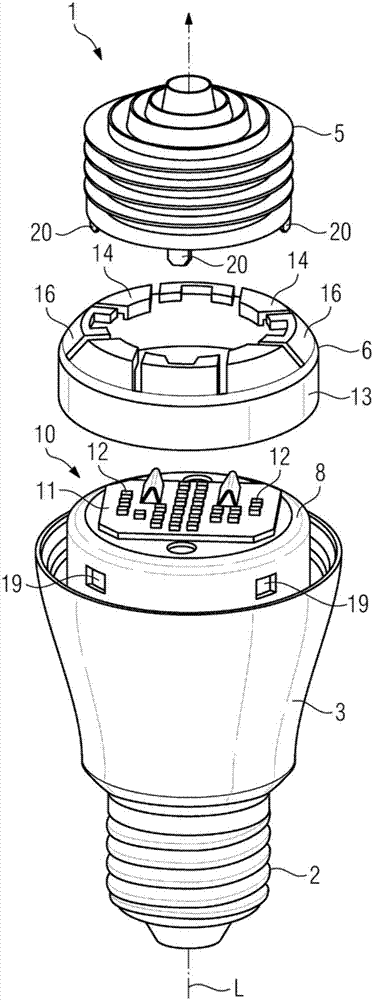

[0039] figure 1 A perspective view of a retrofit lamp 1 for replacing conventional incandescent lamps is shown. A retrofit lamp 1 with a longitudinal axis L has an Edison base 2 (for example of type E27) on its rear end. The Edison base 2 is connected forwardly to a housing 3 , for example made of plastic, which supports or holds a light-transmitting bulb 4 at the front. The bulb 4 houses a light-transmitting optical element (“lens” 5 ) as well as a ring 6 which supports or fixes the lens 5 . The bulb 4 can be transparent or diffuse.

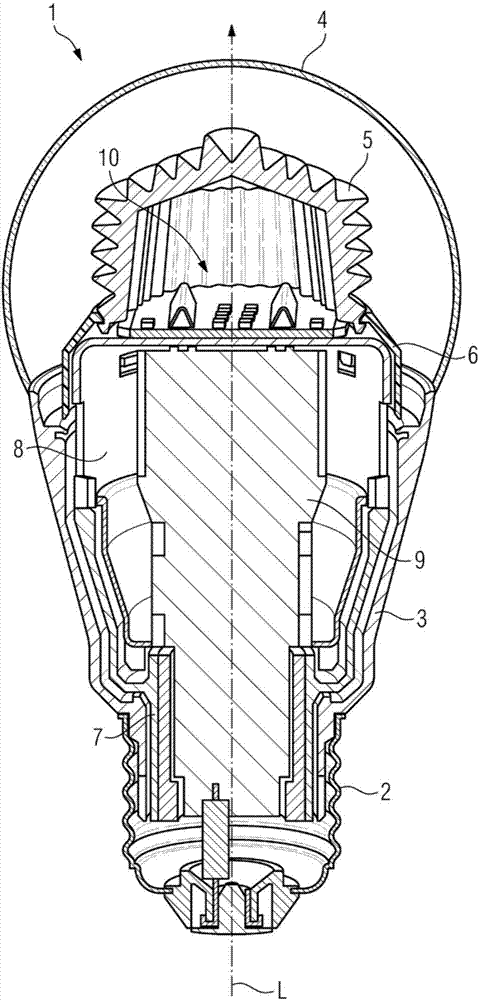

[0040] figure 2 The retrofit lamp 1 is shown in oblique sectional view. The housing 3 laterally surrounds drive housings 7, 8 in which the drive 9 is placed. The drive housings 7 , 8 have a base-side, cup-shaped lower part 7 and an upper, cup-shaped cover, which serves as a heat sink 8 . The lower part 7 can consist of metal or plastic. The heat sink 8 consists here of metal, for example of aluminum.

[0041] The LED module 10 rests on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com