Super high-rise construction escape system

An escape system and super-high-rise technology, applied in life-saving equipment, building components, building rescue, etc., can solve the problems of long elevator lifting time, high maintenance costs, and slow evacuation of personnel, so as to increase the choice of escape routes and reduce maintenance costs , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

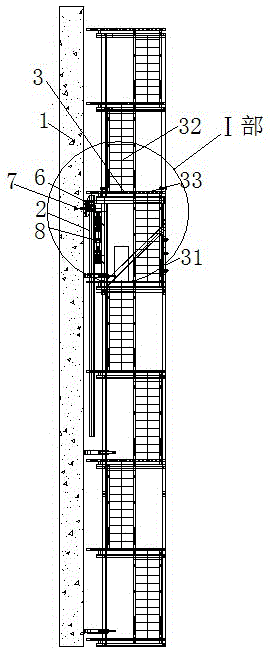

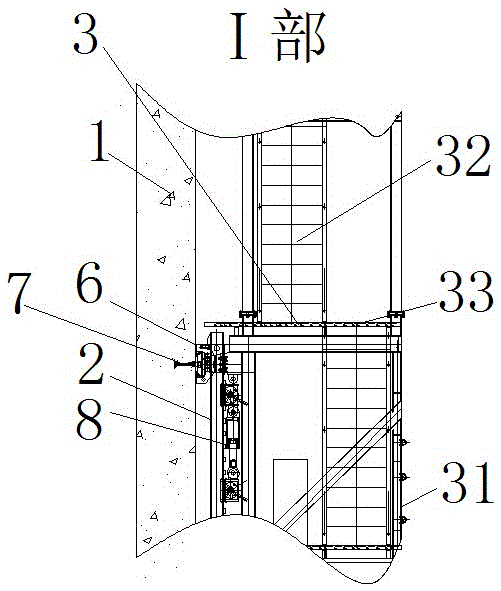

[0024] The present invention includes a track 2 attached to the wall 1, and the track 2 is provided with an escape device 3 that moves up and down along the track 2;

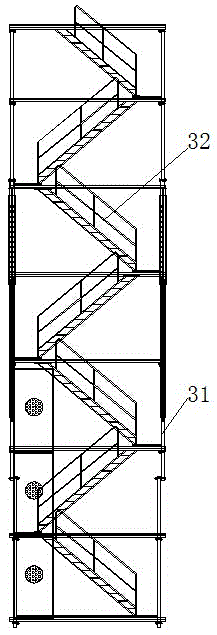

[0025] The escape device 3 includes a frame body 31, the frame body 31 is fixed with a prefabricated staircase 32, and the wall body 1 is provided with a horizontal floor 4 protruding from the wall body (1).

[0026] Ladders 5 are provided on each of the horizontal floors 4 , and the ladders 5 can be overlapped on the corresponding steps of the prefabricated stairs 32 .

[0027] The lower part of each step of the prefabricated staircase 32 is provided with a floor platform slab 33 , and the ladder 5 can be lapped to the floor platform slab 33 .

[0028] The track 2 is connected to the wall body 1 through a wall-attached bearing seat 6 , and the wall-attached bearing seat 6 is fixed on the wall body 1 through a wall embedded part 7 .

[0029] The escape device 3 is driven to move up and down by a hydraulic jacki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com