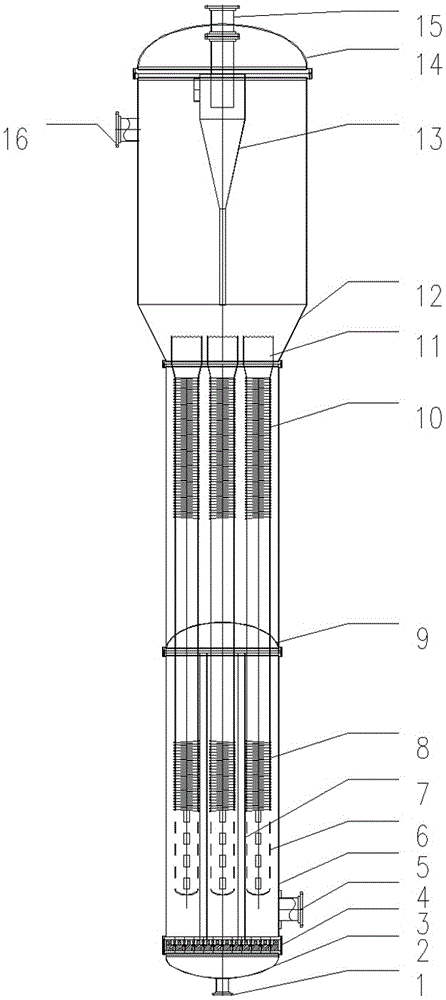

High-efficient multi-phase reactor

A technology of a reactor and a reactor shell, which is applied in the field of gas-liquid-solid three-phase slurry bed reactors, can solve problems such as imperfect design, difficulty in amplification, and failure to achieve the effect of reaction matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

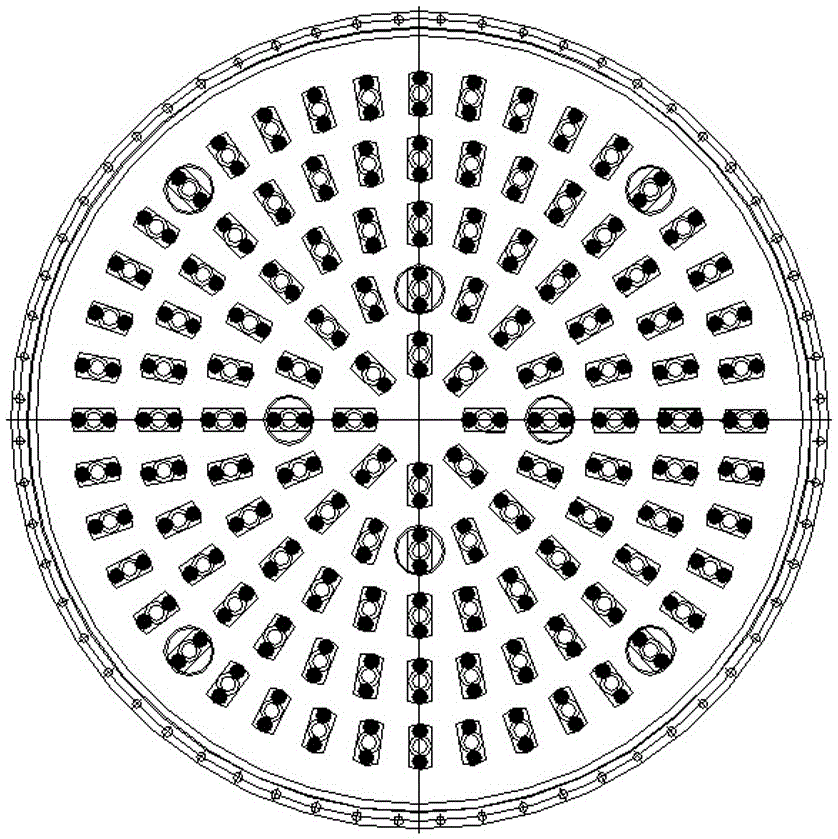

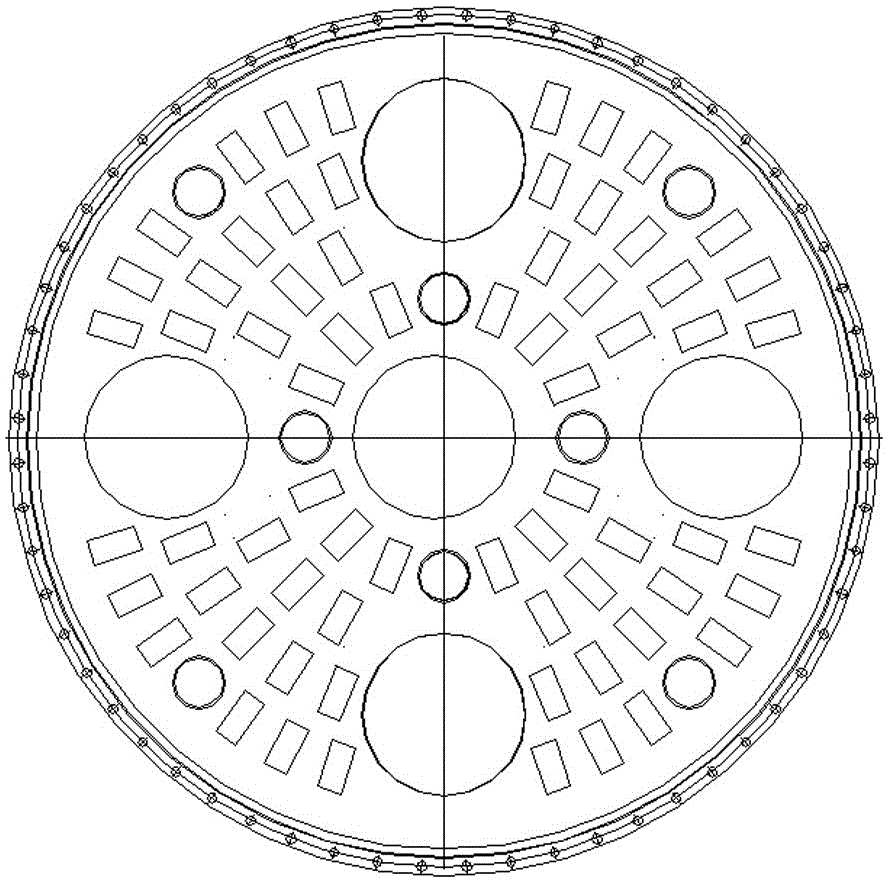

[0015] When the gas enters the bed through the nozzle of the distributor, a large number of small bubbles are formed. Due to the driving effect of the gas flow rate, the slurry in the bed is violently mixed; a part of the gas reacts with the catalyst at the bottom of the reactor, and the gas after the reaction Or the unreacted raw material gas is redistributed through the secondary gas distribution plate in the middle of the inner sleeve during the rising process. After the large bubbles are broken and the fluid flow form is reformed, the diameter of the bubbles becomes smaller and the reaction contact area Increase, the catalytic reaction becomes more intense, and the unreacted raw material gas is further reacted with the fresh raw material gas, and the excess heat of reaction is removed under the action of the heat exchanger; another part of the gas reaches the middle of the reactor through the gas riser, The gas ejects tiny bubbles from the small holes of the gas riser, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com