Forming mesh specially used for high-speed household paper and papermaking equipment

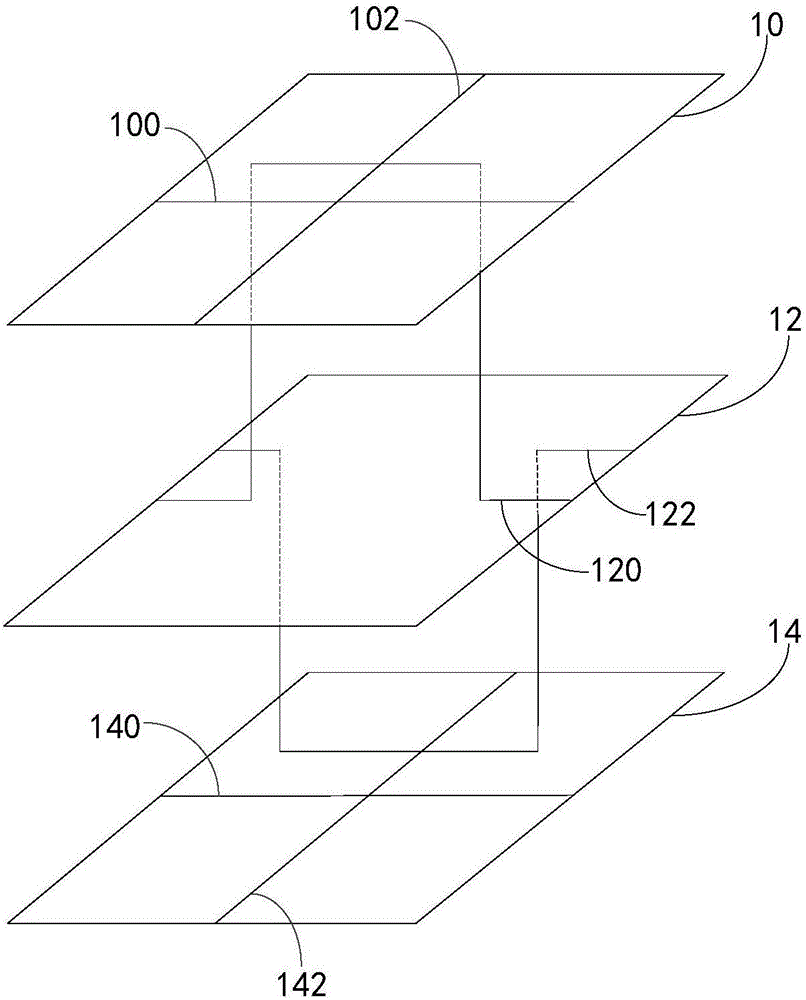

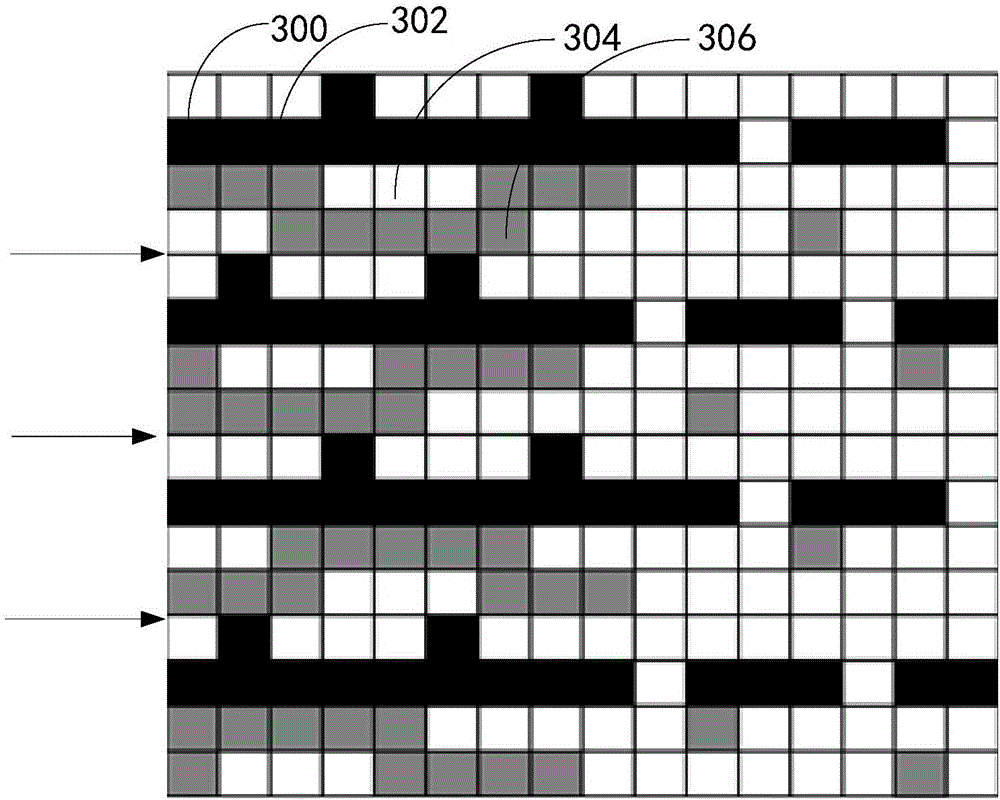

A technology of household paper and forming net, applied in papermaking, paper machine, textile and papermaking, etc., which can solve the problem of low fiber and filler retention rate of household paper, low fiber support index of paper surface, and poor tissue quality of household paper. Obvious mesh marks on the surface of the finished product, etc., to achieve the effect of smooth mesh surface, enhanced stability, and smooth and delicate paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The warp thread of the paper layer adopts polyester monofilament with a diameter of 0.125mm, the weft thread of the paper layer adopts polyester monofilament with a diameter of 0.13mm, and the weft thread of the middle connecting layer adopts polyester monofilament or nylon monofilament with a diameter of 0.12mm. The layer warp adopts polyester monofilament with a diameter of 0.125mm, and the machine layer weft adopts a polyester monofilament with a diameter of 0.25mm. The method in GB / T 24290-2009 "Measurement Method for Paper Forming Wire and Drying Wire" is used for the embodiment The special forming wire for high-speed household paper in 1 was tested for performance, and the test results are shown in Table 1 below.

Embodiment 2

[0023] The warp thread of the paper layer adopts polyester monofilament with a diameter of 0.125mm, the weft thread of the paper layer adopts polyester monofilament with a diameter of 0.13mm, and the weft thread of the intermediate connection layer adopts polyester monofilament or nylon monofilament with a diameter of 0.13mm. The polyester monofilament with a diameter of 0.125mm is used for the warp of the layer, and the polyester monofilament with a diameter of 0.25mm is used for the weft of the machine layer. The above-mentioned high-speed The performance test of the forming wire specially used for household paper is carried out, and the test results are shown in Table 1 below.

[0024] Table 1: Performance test results of forming fabrics for high-speed household paper

[0025] performance

Example 1 result

Example 2 result

Warp density

76 pcs / cm

76 pcs / cm

Weft density

68 pcs / cm

70 pcs / cm

Forming net thickness

0.68mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com