Washing machine with simple clutch

A technology for clutches and washing machines, applied in the field of washing machines, which can solve the problems of easy clutch engagement, easy wear and tear of clutch components, and high production costs, and achieve the effects of long service life, simple structure, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

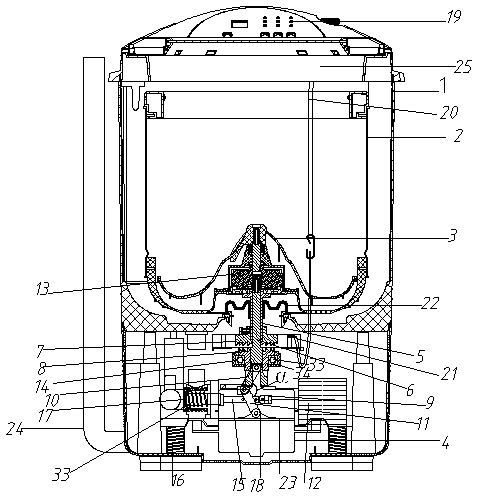

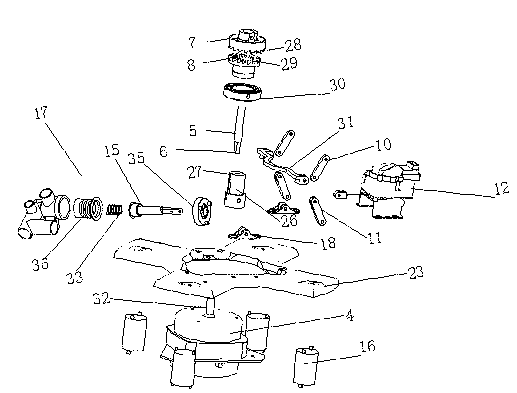

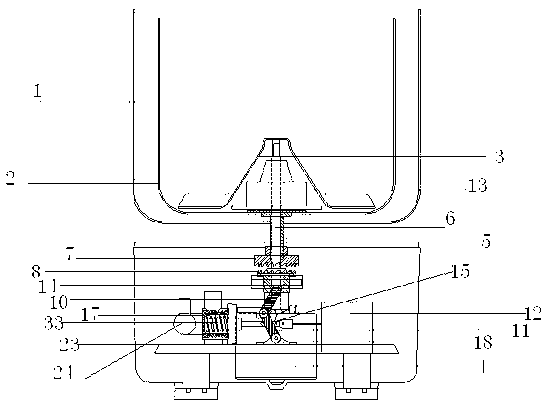

[0026] see now figure 1 and figure 2 Embodiments of the present invention will be described in detail.

[0027] See Figure 1 to Figure 4 A washing machine according to an embodiment of the present invention is shown. It includes: the inside of the box body 1 is used to hold water, and the water can be discharged through the drain valve 17 of the drainage system 24 arranged at the bottom; At the inner bottom of the drying barrel 2, the pulsator 3 is connected with the central shaft 6 through the reducer 13, and the central shaft 6 is driven by the motor 4 fixed on the motor base plate 23, and the central shaft 6 is splined connected with the lower clutch 8, and the lower clutch 8 can slide up and down in the vertical direction of the central axis 6, but cannot rotate relative to the central axis 6; the drying shaft sleeve 5 is integrally connected with the drying barrel 2, the central shaft 6 passes through the drying shaft sleeve 5, and the upper clutch 7 is fixed Set on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com