Method, device and system for detecting product packaging

A technology for product packaging and collection devices, which is applied to measurement devices, material analysis by optical means, instruments, etc., can solve the problems of mismatching processing rates of collection equipment and inspection equipment, low detection efficiency, etc., to reduce inspection congestion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] According to an embodiment of the present invention, an embodiment of a method for detecting product packaging is provided. It should be noted that the steps shown in the flow chart of the accompanying drawings can be executed in a computer system such as a set of computer-executable instructions, and, Although a logical order is shown in the flowcharts, in some cases the steps shown or described may be performed in an order different from that shown or described herein.

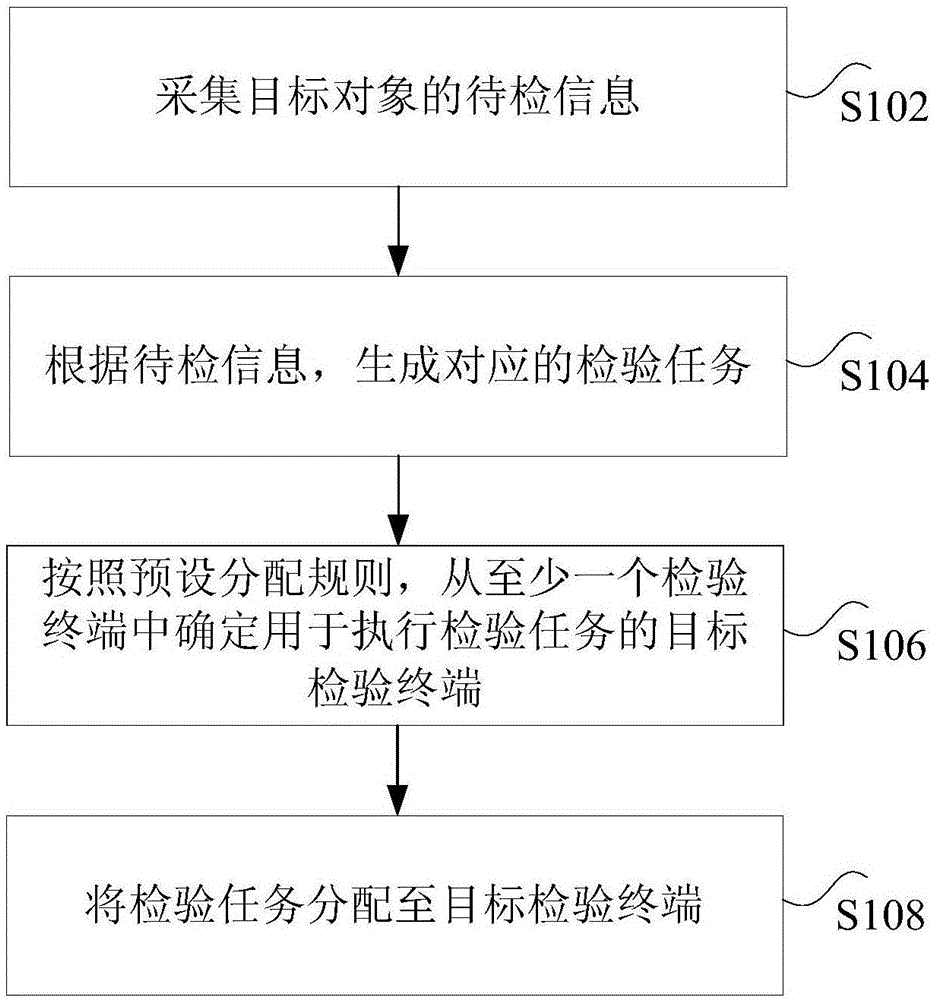

[0026] figure 1 It is a flow chart of a method for detecting product packaging according to an embodiment of the present invention, such as figure 1 As shown, the method includes the following steps:

[0027] Step S102, collecting information about the target object to be checked.

[0028] Specifically, in the above steps, the above-mentioned target object can be any kind of product packaging to be inspected, for example, packing boxes, packaging bottles, packaging bags, etc.; the above-mentioned in...

Embodiment 2

[0070] According to an embodiment of the present invention, a system embodiment for implementing the above method for detecting product packaging is also provided, Image 6 It is a schematic diagram of a system for detecting product packaging according to an embodiment of the present invention, such as Image 6 As shown, the system includes: a collection device 601, a main control computer 603 and at least one inspection terminal (n are shown in the figure, respectively 605-1, 605-2, ... 605-n).

[0071] Wherein, the collection device 601 is used to collect the information to be checked of the target object;

[0072] The main control machine 603 is connected with the acquisition device, and is used to generate corresponding inspection tasks according to the information to be inspected, and determine the target inspection terminal for performing inspection tasks from at least one inspection terminal according to the preset distribution rules, and assign the inspection tasks to ...

Embodiment 3

[0085] According to an embodiment of the present invention, an embodiment of a device for realizing the above method for detecting product packaging is also provided, Figure 9 It is a schematic diagram of a device for detecting product packaging according to an embodiment of the present invention, such as Figure 9 As shown, the device includes: a collection module 901 , a generation module 903 , a determination module 905 and an allocation module 907 .

[0086] Among them, the acquisition module 901 is used to collect the information to be inspected of the target object; the generation module 903 is used to generate the corresponding inspection task according to the information to be inspected; the determination module 905 is used to select from at least one inspection terminal Determine the target inspection terminal used to execute the inspection task; the assignment module 907 is used to assign the inspection task to the target inspection terminal.

[0087] As can be see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com