Solenoid assembly for solenoid directional valve

An electromagnetic reversing valve, electromagnet technology, applied in the direction of an electromagnet with an armature, an electromagnet, etc., can solve the problems of reducing the electromagnetic conversion efficiency, the surface of the coil is not easy to dissipate heat, and easy to generate eddy current phenomenon, so as to improve the electromagnetic conversion efficiency, Conducive to the effect of heat dissipation and eddy current reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and given embodiments, but is not limited thereto.

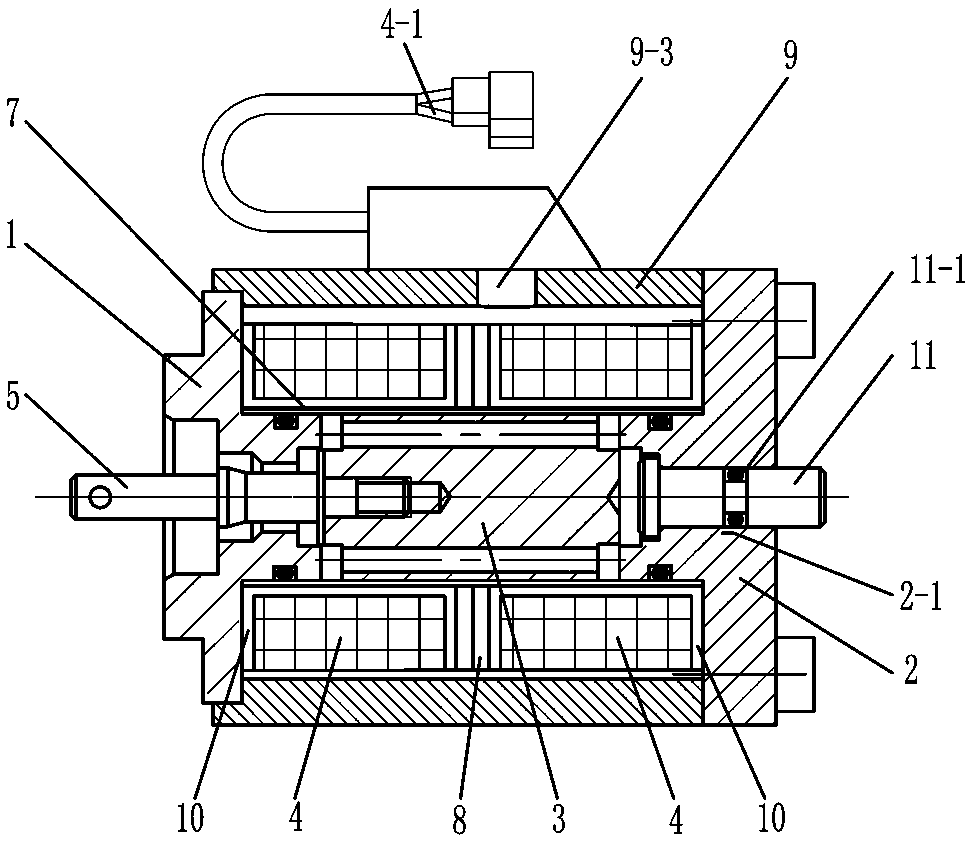

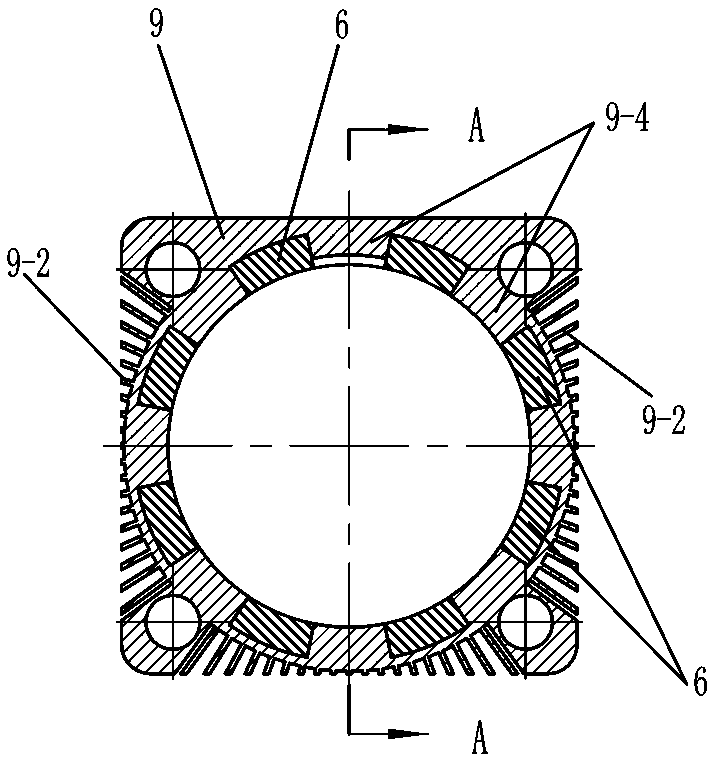

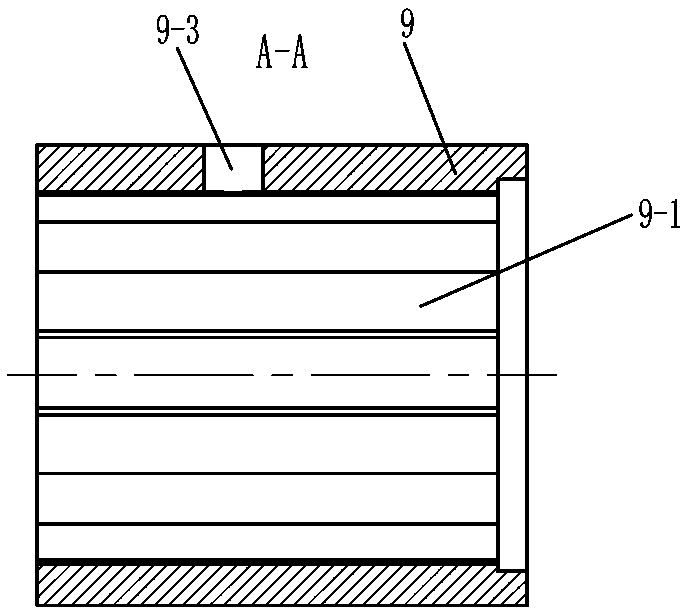

[0025] Such as figure 1 , 2 , 3, 4, 5, and 6, an electromagnet assembly of an electromagnetic reversing valve includes a first iron core 1, a second iron core 2, a push-pull rod 5 and a heat dissipation support 9, and a heat dissipation support 9 Axially install the armature 3, the coil 4, the yoke 6, the magnetic isolation sleeve 7 and the magnetic conduction ring 8 in the through hole 9-1;

[0026] The first iron core 1 and the second iron core 2 are respectively arranged at both ends of the heat dissipation support 9;

[0027] One end of the armature 3 is assembled or integrated with one end of the push-pull rod 5, and the two ends of the magnetic isolation sleeve 7 are respectively assembled, connected or welded on the first iron core 1 and the second iron core 2, and the magnetic isolation The sleeve 7 is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com