Cattlehide bag bonding device

A kraft bag and bonding technology, which is applied in the field of gluing paper bags, can solve the problems of inaccurate seam alignment, damage to the kraft bag, and the kraft bag is not easy to remove, and achieves the effect of reliable bonding, preventing sticking, and preventing glue from condensing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

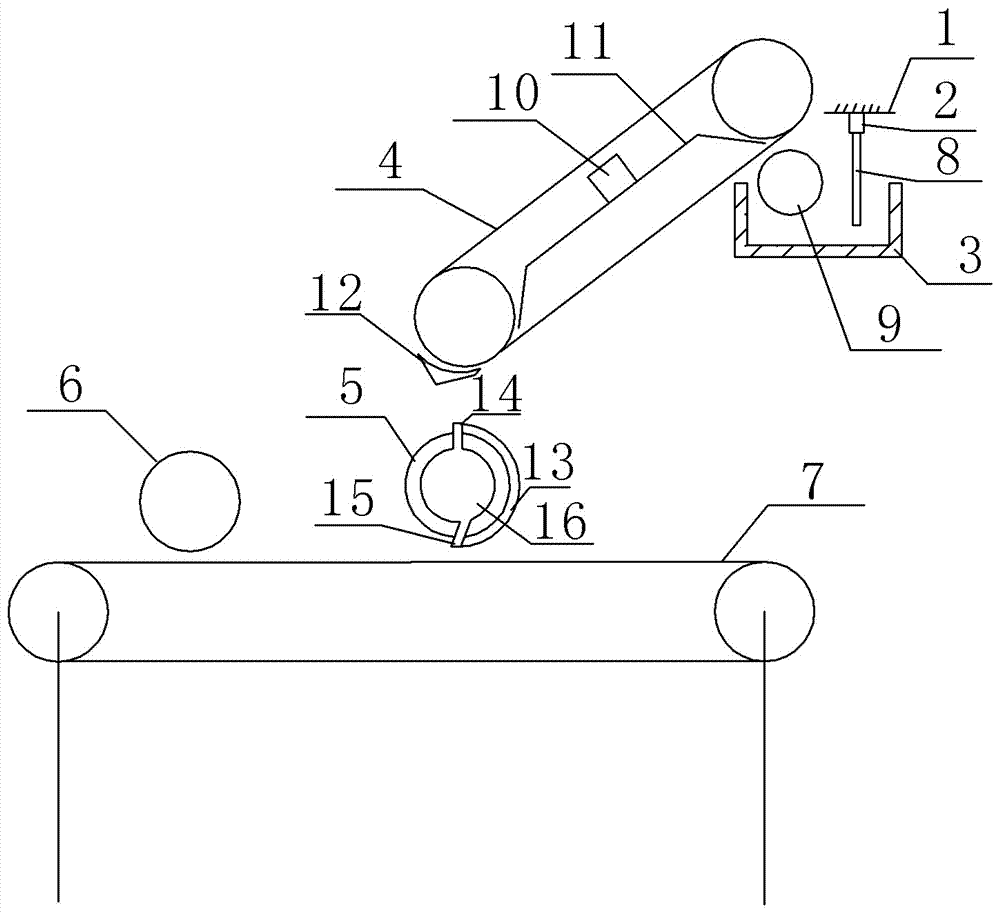

[0016] Such as figure 1 The kraft bag bonding device shown in the figure includes, from right to left and from top to bottom, a frame 1, a swing cylinder 2, a plastic container 3, a second conveyor belt 4 arranged obliquely, a guide wheel 5, and a roller 6 and the first conveyor belt 7 arranged horizontally. The swing cylinder 2 is fixedly connected to the frame 1 by bolts, and a stirring rod 8 is welded on the transmission shaft of the swing cylinder 2, and the lower end of the stirring rod 8 extends into the glue container 3 welded on the frame 1; There is the gluing wheel 9 that is rotatably connected to the sidewall of the gluing pan 3 . The space formed by the second conveyor belt 4 and the second drive wheel is provided with a negative pressure pump 10, and the negative pressure pump 10 is welded on the frame 1; On the inner surface of the second conveyor belt 4 on one side of the dish 3, the second conveyor belt 4 has fine holes. Frame 1 is welded with shovel blade 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com