Integrated type high-capacity small-size water tank

A large-capacity, integrated technology, applied in the direction of large containers, containers, packaging, etc., can solve the problems of limited space height in the production workshop, the inability to install large water tanks, and small water tanks that cannot fully meet the needs of use, so as to improve the convenience of use , Improving the effect of easy installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

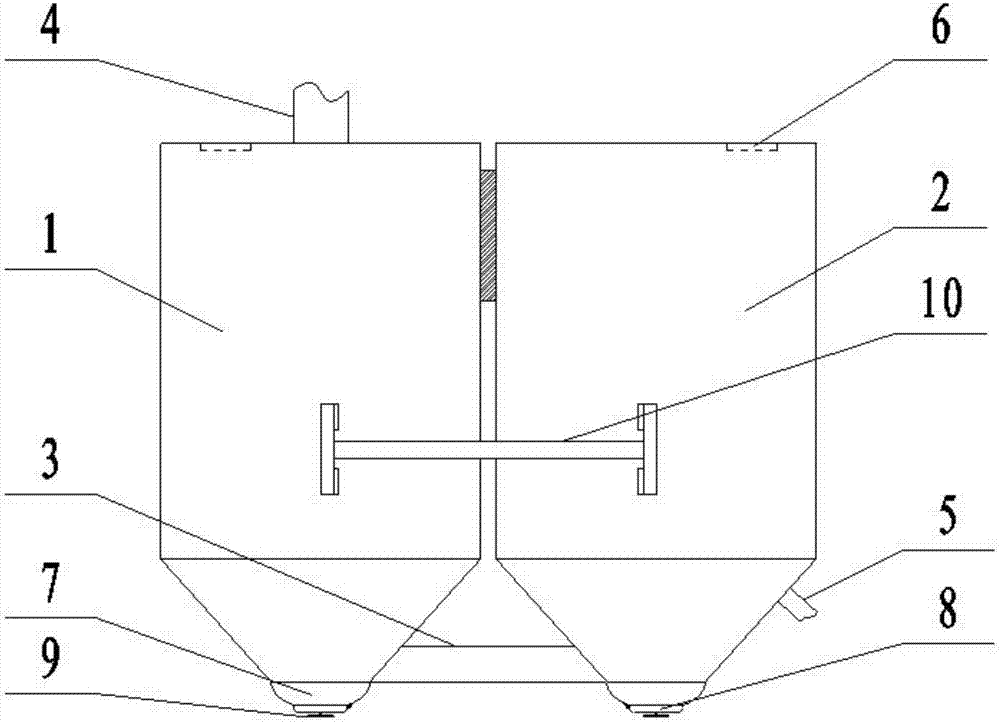

[0016] see figure 1 , the present invention provides a technical solution: an integrated large-capacity small water tank, including a sub-water tank A1, a sub-water tank B2, a connecting pipe 3, a water inlet pipe 4 and a water outlet pipe 5, the sub-water tank A1 and the sub-water tank B The upper half of 2 is a cylindrical structure with the same diameter, the lower half of the sub-tank A 1 and the sub-tank B 2 are inverted cones, and the bottom of the sub-tank A 1 and the sub-tank B 2 passes through The connecting pipe 3 conducts, and the top cover of the sub-water tank A1 and the sub-water tank B2 is provided with a through hole 6, the water inlet pipe 4 is fixedly arranged on the top cover of the sub-water tank A1, and the outlet The water pipe 5 is welded and arranged at the outer lower end of the sub-water tank B 2 . Its structure is simple. Through the cooperation of water tank A 1, sub-water tank B 2, connecting pipe 3, water inlet pipe 4 and water outlet pipe 5, two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com