Pipe conveying device

A pipeline transportation and pipeline technology, which is applied in the field of pipeline transportation devices, can solve problems such as easy to be stained with dust, the dust of the installer falls in other places, and affects the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below by means of specific embodiments:

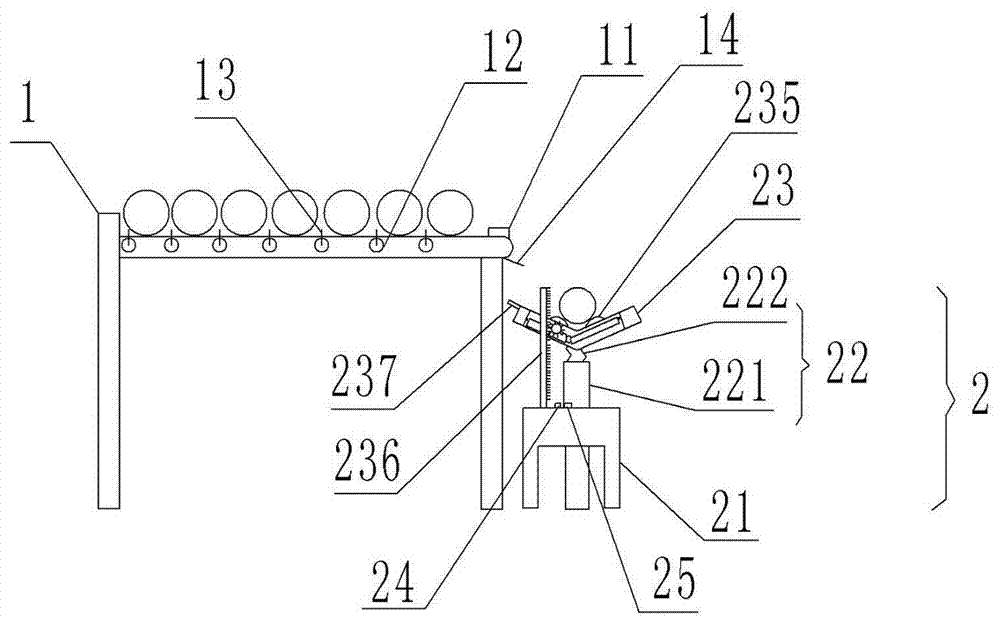

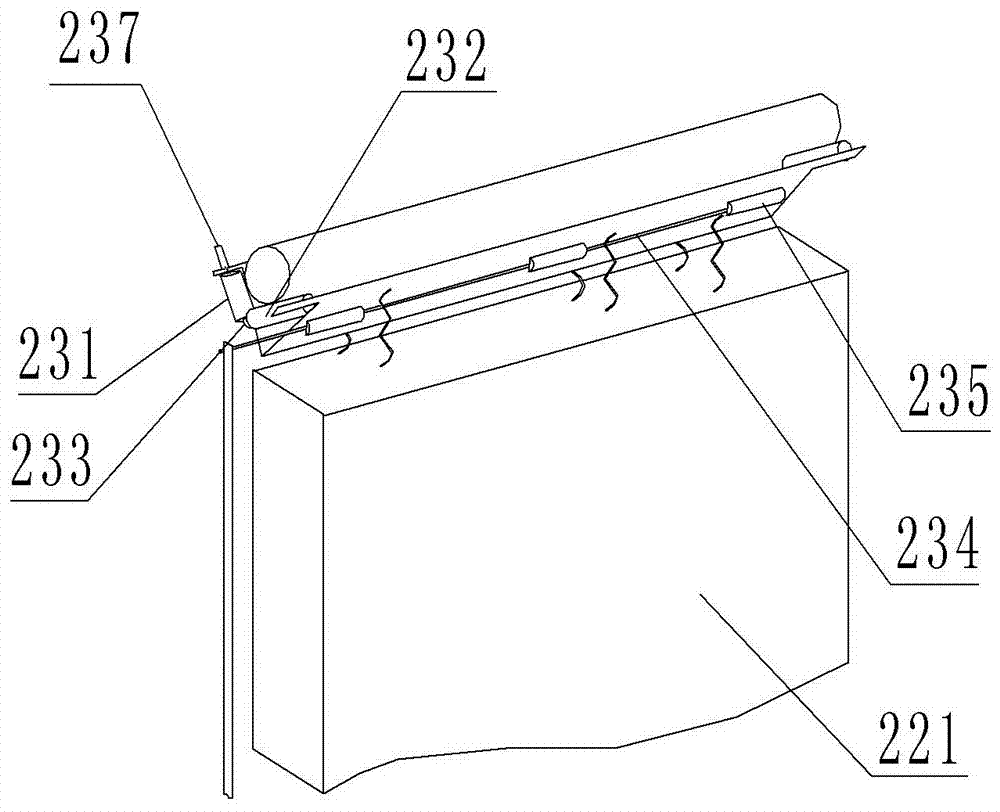

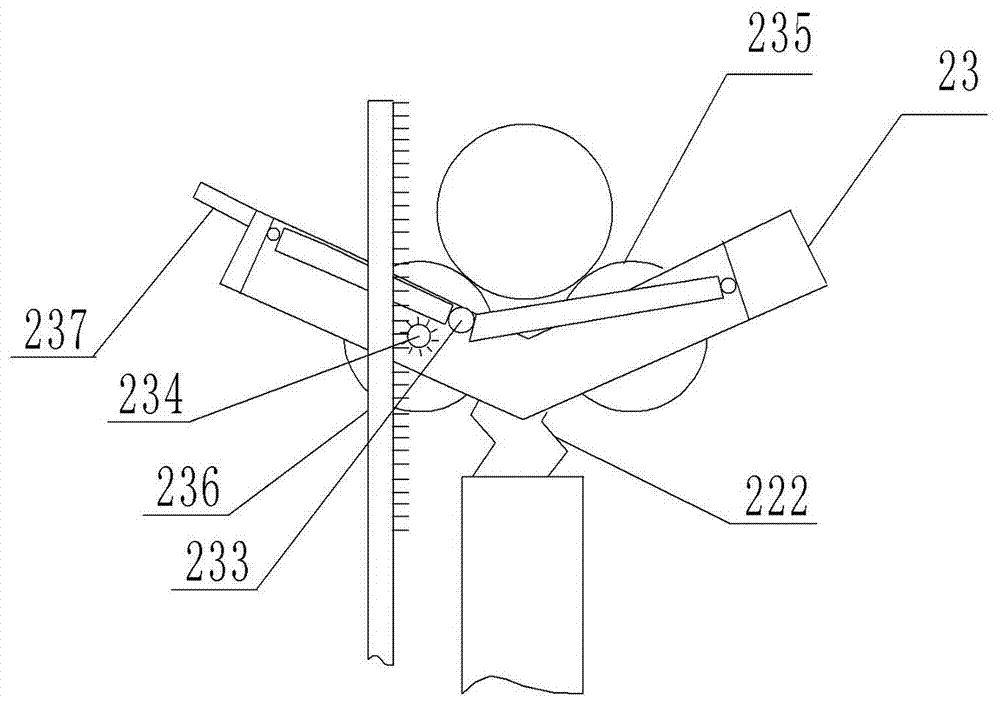

[0030] The reference signs in the drawings of the description include: storage rack 1, rubber protrusion 11, toggle shaft 12, paddle 13, switch 14, pick-up mechanism 2, support platform 21, support seat 22, seat body 221, spring 222, pick and place part 23, short roller 231, long roller 232, magnet 233, rotating shaft 234, dust removal roller 235, first rack 236, dial bar 237, groove 238, sliding hole 239, first electromagnet 24, the first Two electromagnets 25.

[0031] Such as figure 1 , figure 2 and image 3 As shown, the pipeline conveying device includes a storage rack 1, the left side of the storage rack 1 is fixedly connected with a baffle to prevent the pipeline from falling, and the right side of the storage rack 1 is fixedly connected with a rubber protrusion 11. The storage rack 1 is provided with a toggle portion that can toggle the pipeline. The togglin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com