A kind of preparation method of porous carbon material

A porous carbon material and glue technology, applied in carbon preparation/purification, etc., can solve the problems of difficult to obtain raw materials, complex synthesis process, long synthesis cycle, etc., and achieve high product yield and purity, simple process and easy to obtain Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

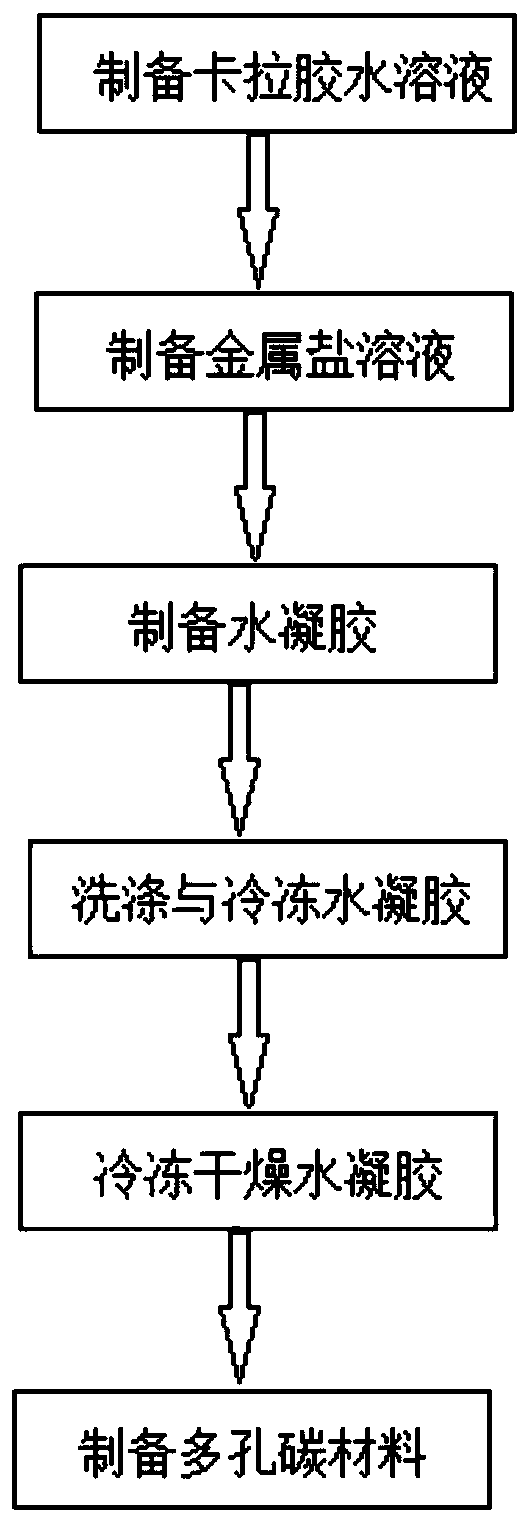

[0030] The process of the preparation method of the porous carbon material involved in this example includes six steps: preparation of carrageenan aqueous solution, preparation of metal salt solution, preparation of hydrogel, washing and freezing of hydrogel, freeze-drying of hydrogel and preparation of porous carbon material :

[0031] (1) Preparation of carrageenan aqueous solution: weigh 3g of IOTA carrageenan, set the stirrer speed to 800-1000r / min, set the heat source temperature to 60-80°C, and dissolve the carrageenan under magnetic stirring and heating conditions In 200ml of twice-distilled water, stop heating after the carrageenan is completely dissolved, remove the heat source, and obtain a carrageenan aqueous solution with a concentration of 1-3% by mass, and leave the carrageenan aqueous solution at room temperature for 10-20 minutes. It is naturally cooled to 50-60°C to complete the preparation of the carrageenan aqueous solution;

[0032] (2), prepare metal salt...

Embodiment 2

[0040] The process of the preparation method of the porous carbon material involved in this example includes six steps: preparation of carrageenan aqueous solution, preparation of metal salt solution, preparation of hydrogel, washing and freezing of hydrogel, freeze-drying of hydrogel and preparation of porous carbon material :

[0041] (1) Preparation of carrageenan aqueous solution: weigh 2g of IOTA carrageenan, set the stirrer speed to 800-1000r / min, set the heat source temperature to 60-80°C, and dissolve the carrageenan under magnetic stirring and heating conditions In 200ml of twice-distilled water, stop heating after the carrageenan is completely dissolved, remove the heat source, and obtain a carrageenan aqueous solution with a concentration of 1-3% by mass, and leave the carrageenan aqueous solution at room temperature for 10-20 minutes. It is naturally cooled to 50-60°C to complete the preparation of the carrageenan aqueous solution;

[0042] (2), prepare metal salt...

Embodiment 3

[0048] The process of the preparation method of the porous carbon material involved in this example includes six steps: preparation of carrageenan aqueous solution, preparation of metal salt solution, preparation of hydrogel, washing and freezing of hydrogel, freeze-drying of hydrogel and preparation of porous carbon material :

[0049] (1) Preparation of carrageenan aqueous solution: Weigh the IOTA-type carrageenan with a set quality, set the stirrer speed to 800-1000r / min, and the heat source temperature to 60-80°C, under magnetic stirring and heating conditions Dissolve carrageenan in 200ml of twice-distilled water. After the carrageenan is completely dissolved, stop heating and remove the heat source to obtain an aqueous solution of carrageenan with a concentration of 1-3% by mass. Put the aqueous solution of carrageenan at room temperature. Allow it to cool naturally to 50-60°C for 10-20 minutes to complete the preparation of the carrageenan aqueous solution;

[0050] (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com