Generator oil tank anti-oil mist overflow and condensation deposition structure

A technology for generators and oil tanks, which is applied in hydroelectric power generation, engine components, engine sealing, etc. It can solve the problems of insulation accidents and environmental pollution caused by oil mist, and achieve the effect of reducing the processing burden and reducing the amount of oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

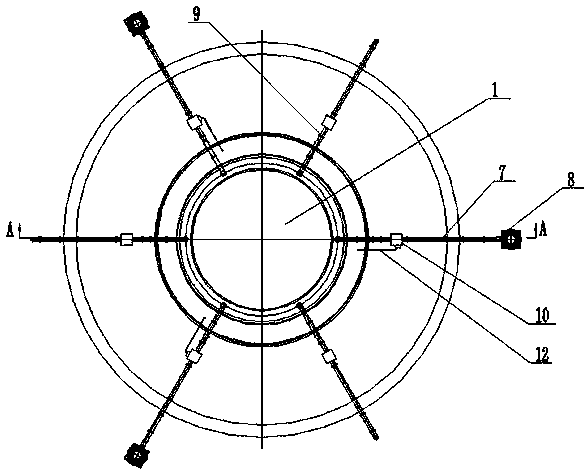

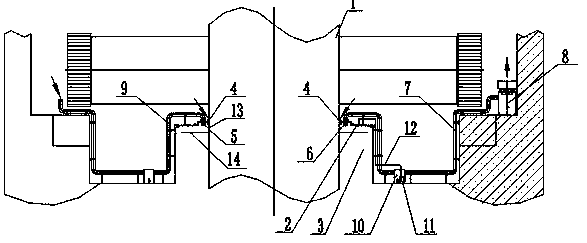

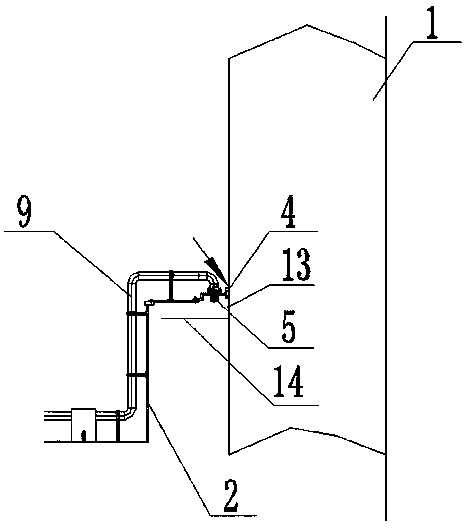

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0021] see figure 1 , 2 3. A generator oil tank anti-oil mist overflow and condensation deposition structure, including a generator shaft 1, an oil tank sealing cover 2, and the oil tank sealing cover 2 seals the space at the lower part of the generator shaft 1 to form an oil tank 3 for storing lubricating oil; At least one ring of sealing layer 4 is provided on the outer surface of the intersection of the oil tank sealing cover 2 and the generator shaft 1, and the sealing layer 4 can be made into a toothed structure to form sealing teeth, which reduces friction to improve service life. The layer 4 is arranged along the outer circumferential surface of the generator rotating shaft 1 , wound on the outer circumferential surface of the generator rotating shaft 1 , and blocks the gap between the generator rotating shaft 1 and the oil tank sealing cover 2 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com