Liquid-cooled motor shell and manufacturing method thereof

A motor casing and liquid cooling technology, which is applied in the manufacture of motor generators, casings/covers/supports, electrical components, etc., can solve problems such as safety accidents, inner wall thickness of the casing, and easy leakage of liquid, so as to improve production efficiency , reduced wall thickness, easy to install and fix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

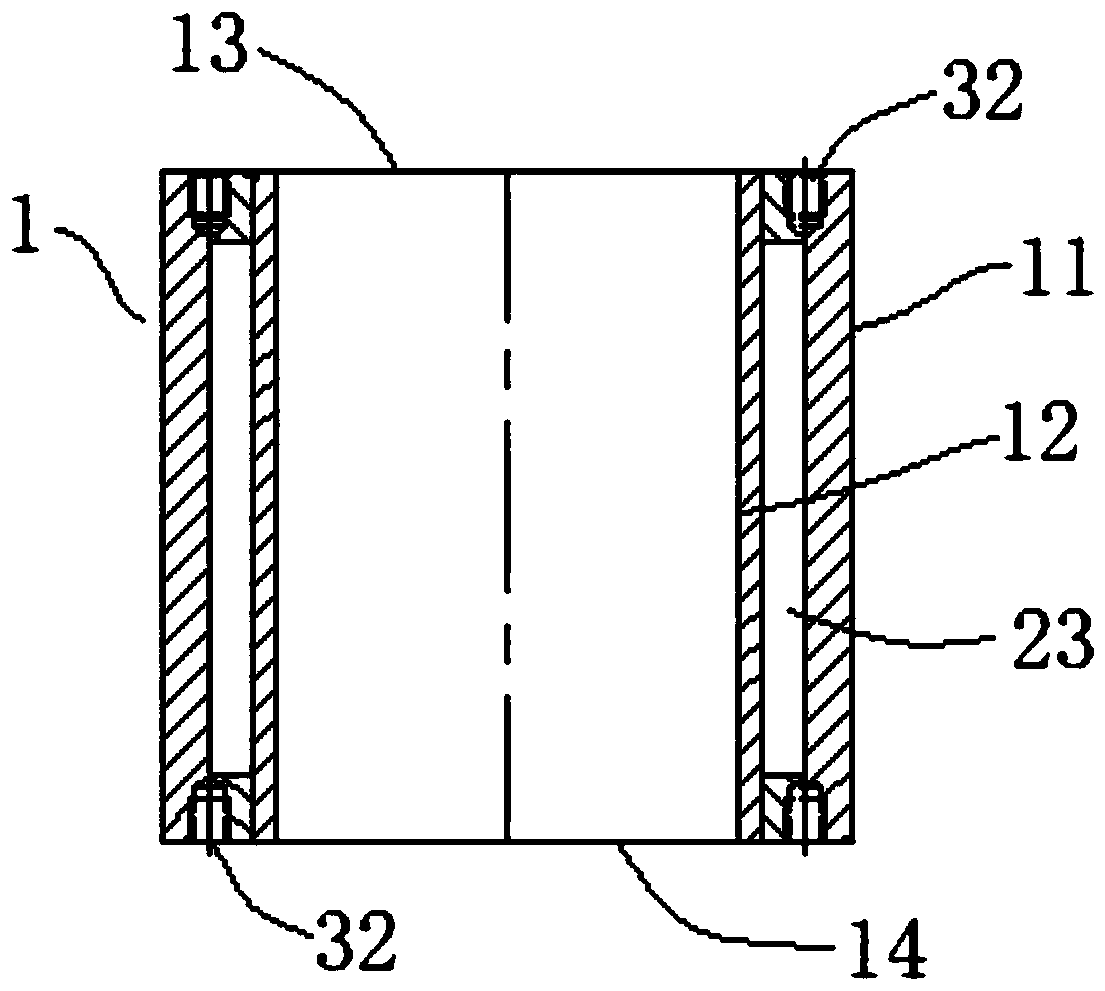

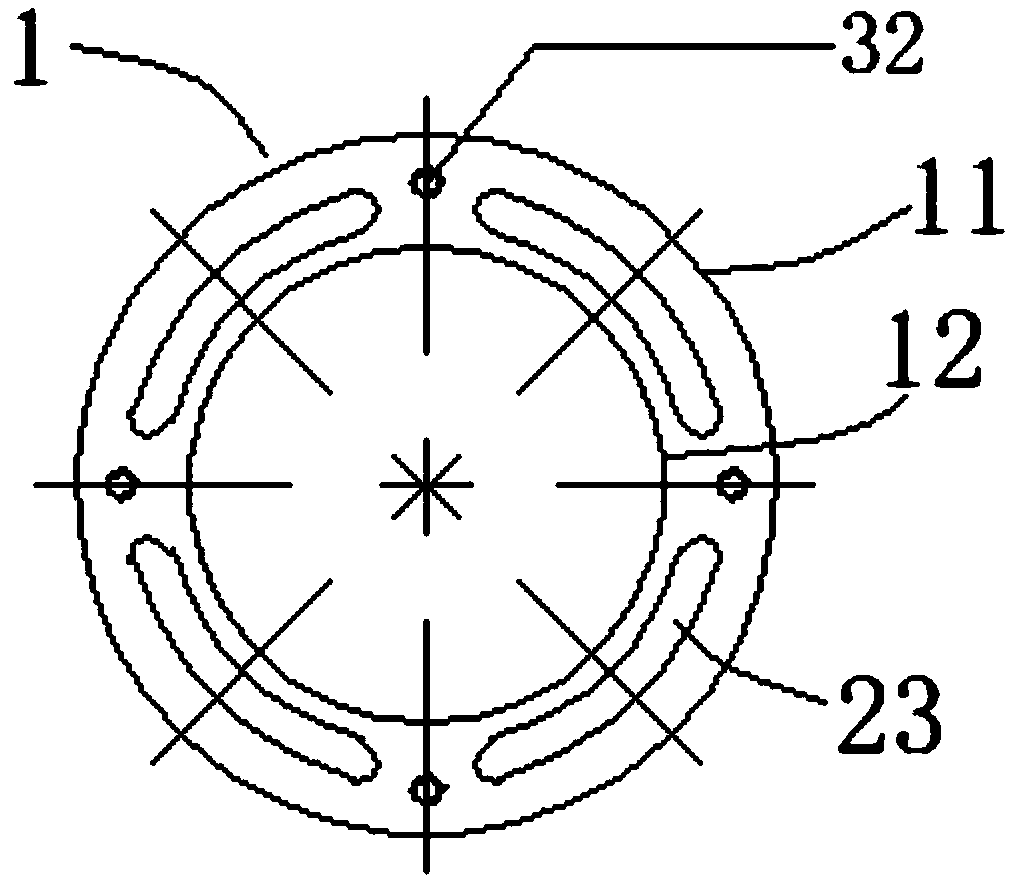

[0093] Such as figure 1 , figure 2 As shown, in the prior art, the threaded holes 32 of the upper end face 13 and the lower end face 14 of the motor casing are usually on the corresponding two ends of the casing wall. In order to ensure the overall strength of the motor after assembly, the size of the threaded holes 32 will be There are corresponding design requirements. When designing the wall thickness of the corresponding shell 1, it is necessary to consider adding a certain thickness on both sides of the threaded hole 32 to ensure the strength of the hole. In particular, there is a U-shaped coolant channel 23 inside the wall of the liquid-cooled casing. The two ends of the casing are welded and sealed by sealing blocks. Adding threaded holes 32 on both ends will increase the difficulty of welding, affect the sealing of the welding and cause coolant leakage, especially to the inside of the motor. The coolant and the motor Contact with internal parts can easily cause safet...

Embodiment 2

[0100] Such as Figure 3-Figure 8As shown, in another preferred embodiment mentioned in the present invention, a liquid-cooled motor casing includes not only all the technical features mentioned in Embodiment 1, but also a sealing structure for the cooling liquid channel 23 . The sealing structure includes a continuous U-shaped cooling liquid channel 23 arranged in the housing 1, and the two ends of the housing are located on the inner side of the continuous U-shaped cooling liquid channel 23. Annular blocking protrusions 24 are arranged, and the blocking protrusions 24 are connected with the housing. 1 is coaxial, and the two blocking protrusions 24 are integrally formed with the housing 1; the two ends of the housing 1 are located outside the blocking protrusions 24, and an annular sealing block 25 that can seal the continuous U-shaped coolant passage 23 is provided ; Between the sealing block 25 and the blocking protrusion 24, between the sealing block 25 and the housing 1 ...

Embodiment 3

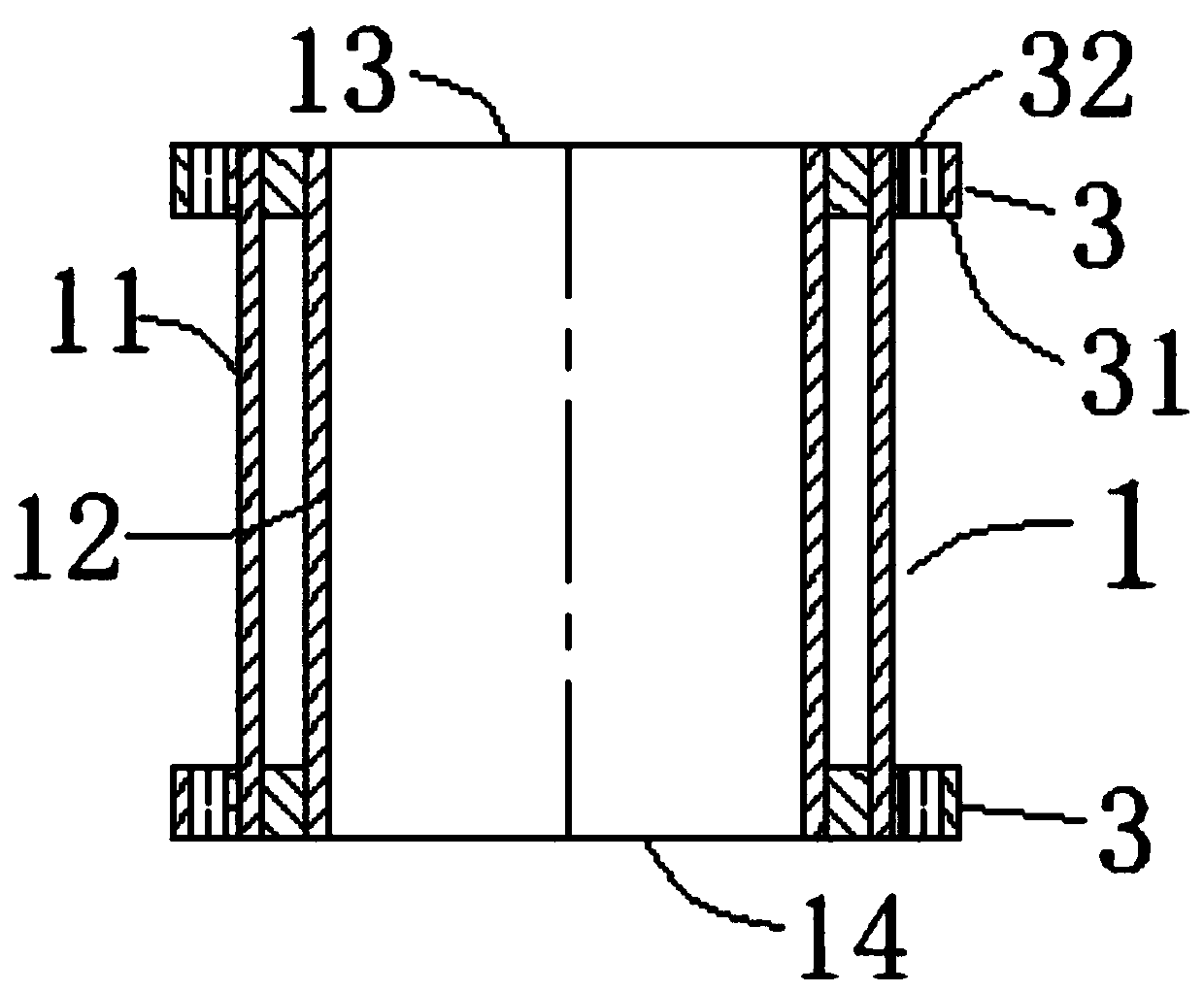

[0103] Such as Figure 3-4 , Figure 9-11 As shown, in another preferred embodiment of the present invention, as an improvement of Embodiment 2, the lug 31 is installed on the outside of the sealing block 25, and the lug 31 can be installed on the sealing block by welding or casting. 25 on.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com