Water gate pump station anti-seepage structure

A technology of anti-seepage and sluice, which is applied in the direction of pumping stations, water supply devices, water conservancy projects, etc., can solve problems such as cracks in the sluice floor and reduced anti-seepage performance of the sluice floor, so as to improve the anti-seepage performance, improve connection stability, reduce seepage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

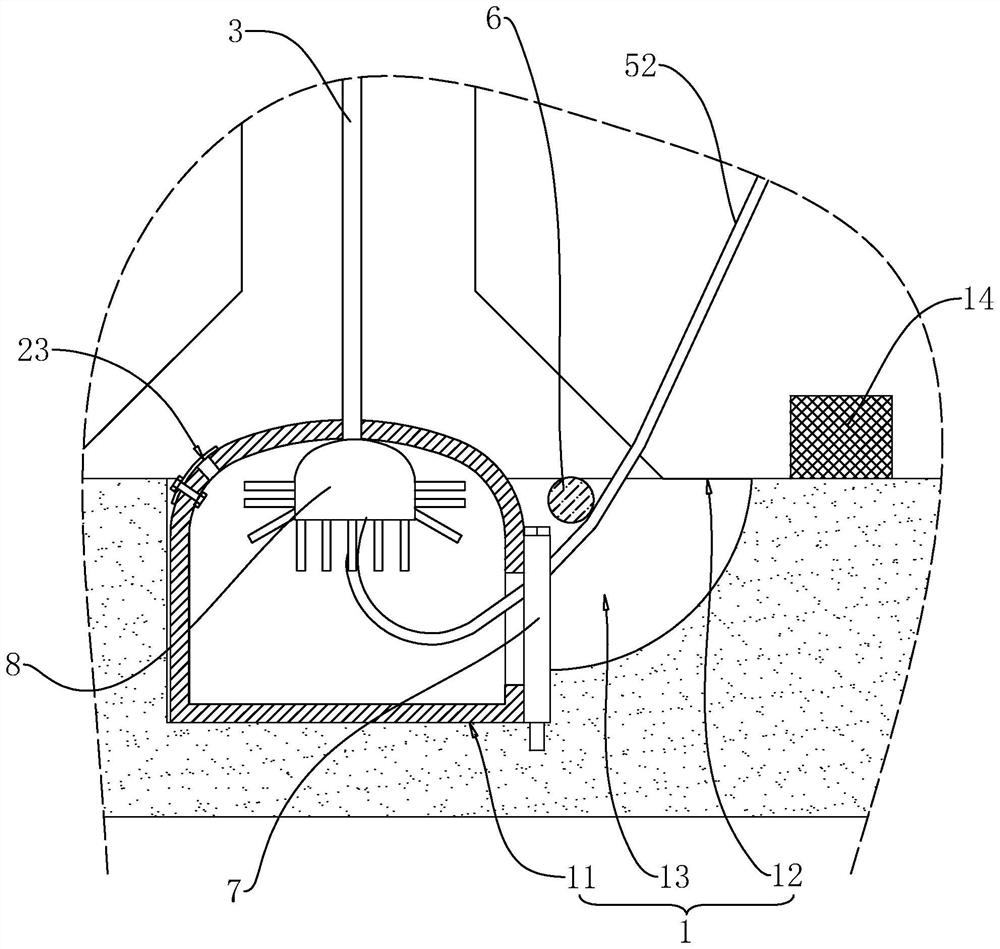

[0035] Attached to the following Figure 1-4 This application will be described in further detail.

[0036]Sluice gates will be installed at the water inlet and outlet of the pumping station. The bottom of most sluice chambers is made of concrete pouring sluice floor. Due to the load during the operation of the sluice gate, the sluice floor will inevitably produce large vertical and horizontal deformation. It is easy to cause cracks in the bottom plate of the sluice, which reduces the anti-seepage performance of the bottom plate of the sluice.

[0037] The embodiment of the present application discloses an anti-seepage structure of a sluice pump station, so as to improve the anti-seepage performance of the bottom plate of the sluice.

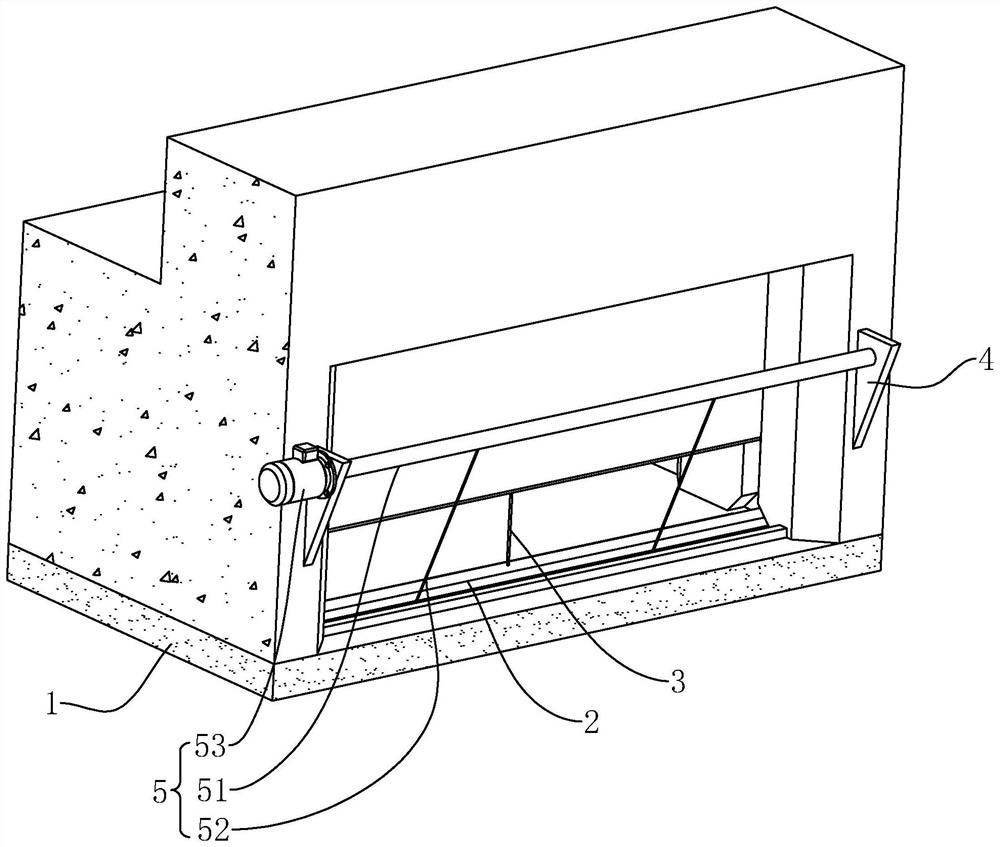

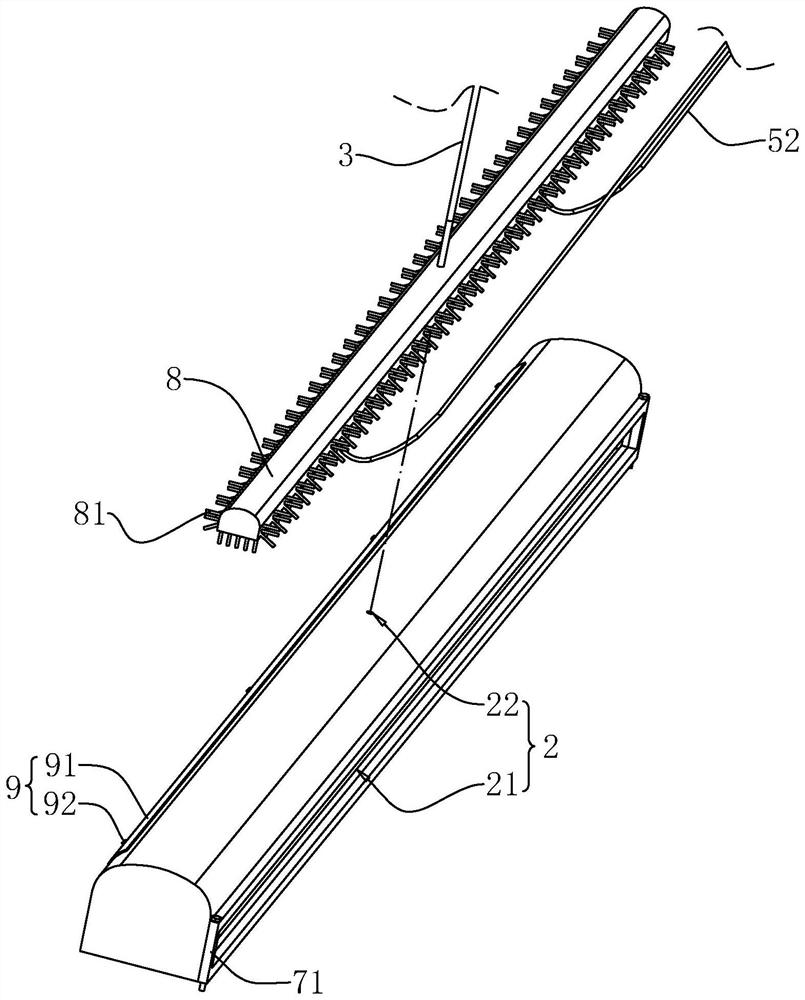

[0038] refer to figure 1 and figure 2 , an anti-leakage structure of a sluice pump station includes a sluice bottom plate 1, an elastic unloading water bag 2, a connecting rope 3 and a connecting foundation 4, wherein the surface of the slui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com