Laser tracker with two measuring function alities

A technology of laser tracker and function, applied in the field of laser tracker, can solve the problems of high cost and complicated production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

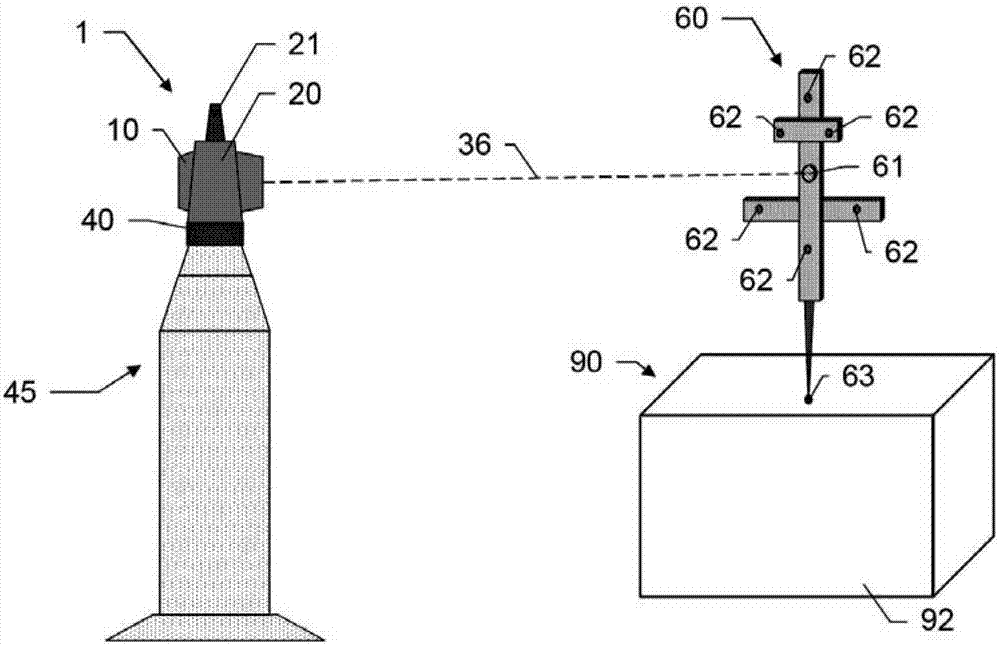

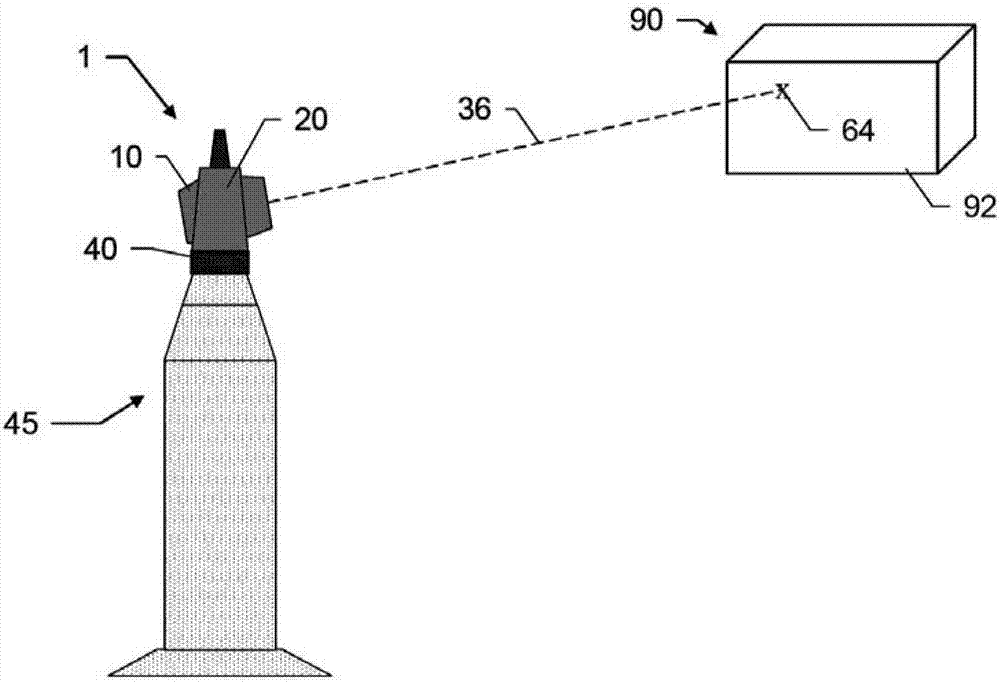

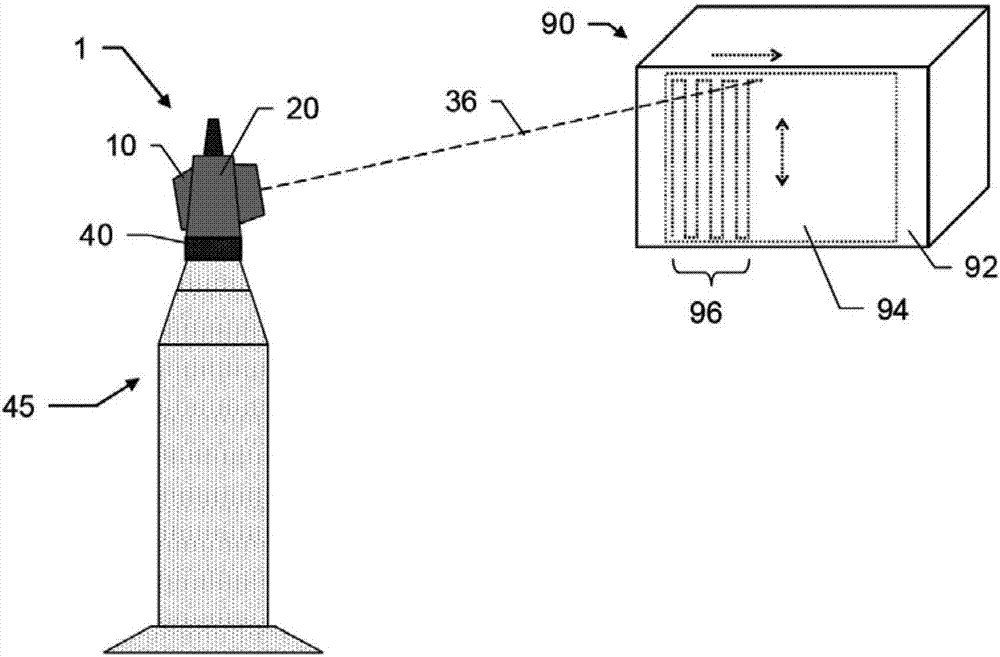

[0046] figure 1 , figure 2 and image 3 An exemplary embodiment of a laser tracker 1 according to the invention is shown. The shown laser tracker 1 comprises a base 40 , a support body 20 mounted on the base 40 and having a handle 21 , and a beam guiding unit 10 mounted on two struts of the support body 20 . The laser tracker 1 is arranged on a support 45 and comprises: a control and evaluation unit; an angle sensor for detecting the angle of rotation of the beam guiding unit 10 relative to the base 40; and an optical distance measuring unit with at least one first beam source (e.g. one or more laser diodes or superluminescent LEDs), at least one first detection unit (e.g. electronic distance measurement unit), absolute distance unit (ADM) or interferometer unit (IFM) (not shown here) . With suitable synchronization of the angle sensors, the two angles and at least one distance determined by the first measurement radiation 36 can be combined to form the 3D polar coordinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com