Automatic vacuum electrolyte filling device

A filling device and electrolyte technology, applied in circuits, electrical components, battery pack components, etc., can solve the problem of low battery work efficiency, battery products that do not meet the requirements of the international market, and inability to real-time know the capacity of the electrolyte to be filled. Liquid level etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

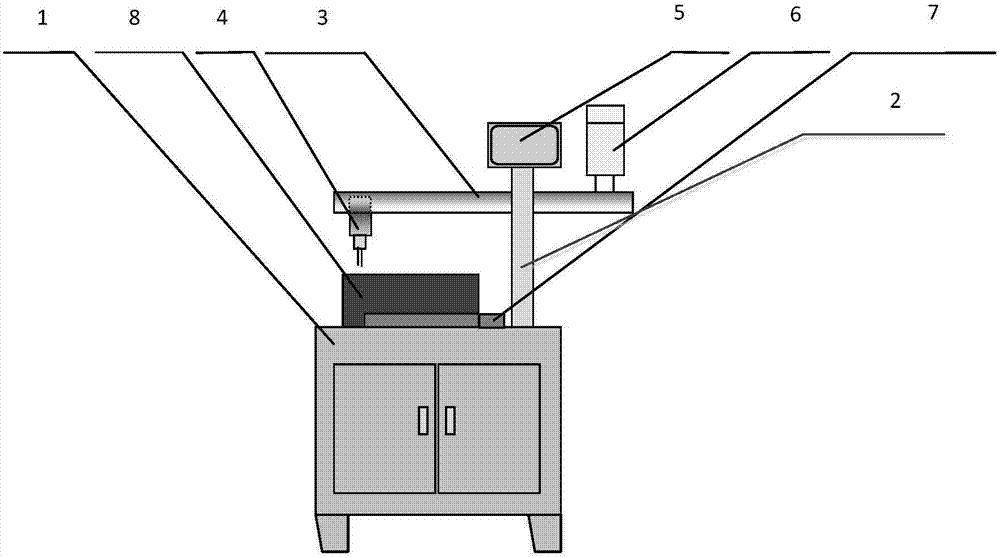

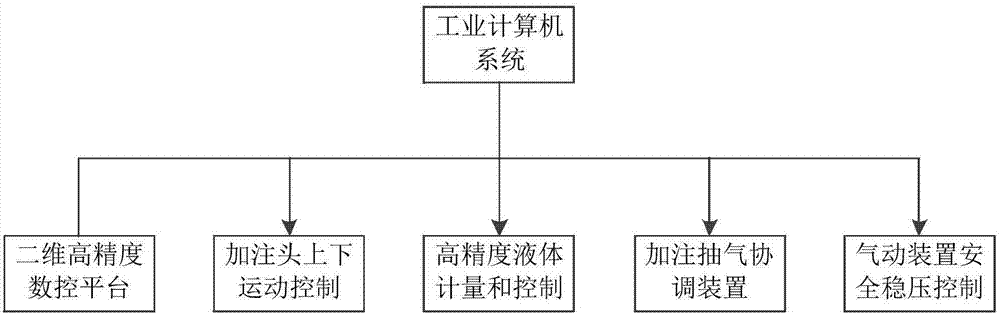

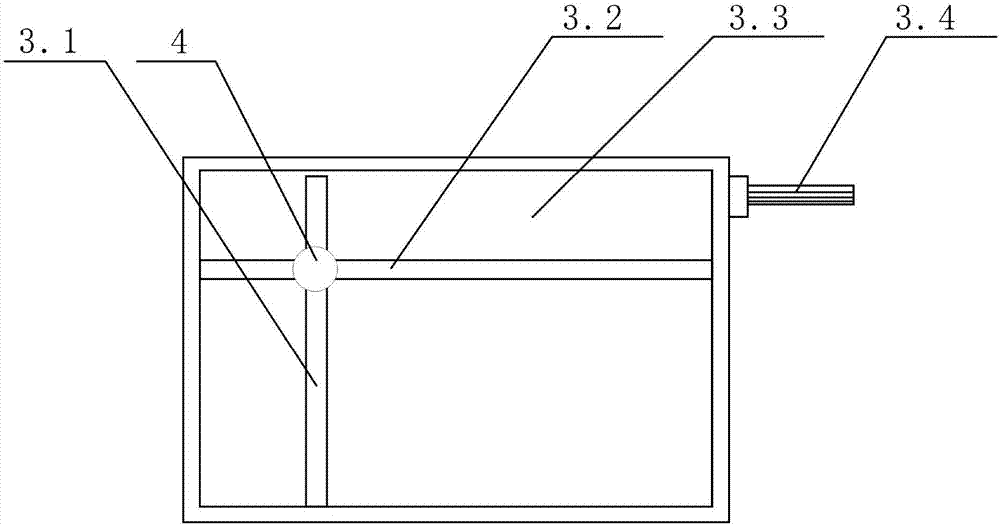

[0028] Such as figure 1 As shown, an automatic electrolyte vacuum filling device includes a frame main body 1, a vertical beam 2, a numerical control platform 3, a vacuum filling head 4, a touch screen 5 of a numerical control computer system, an electrolyte hopper 6, and a battery installation fixture 7. The bottom of the vertical beam 2 is vertically connected with the frame main body 1, the battery installation jig 7 is installed on the top of the rack main body 1, the battery to be filled 8 is installed on the battery installation jig 7, and the top of the vertical beam 2 is connected to the touch screen 5 of the numerical control computer system , one end of the numerical control platform 3 is connected to the vacuum filling head 4 , and the other end of the numerical control platform 3 is connected to the electrolyte hopper 6 . The numerical control platform 3 is used to drive the high-precision positioning of the vacuum filling head 4 in the two-dimensional plane, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com