Composite cooling system

A technology of composite cooling and coolant, applied in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve problems such as application limitations, and achieve uniform flow, ensure heat dissipation, and ensure uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

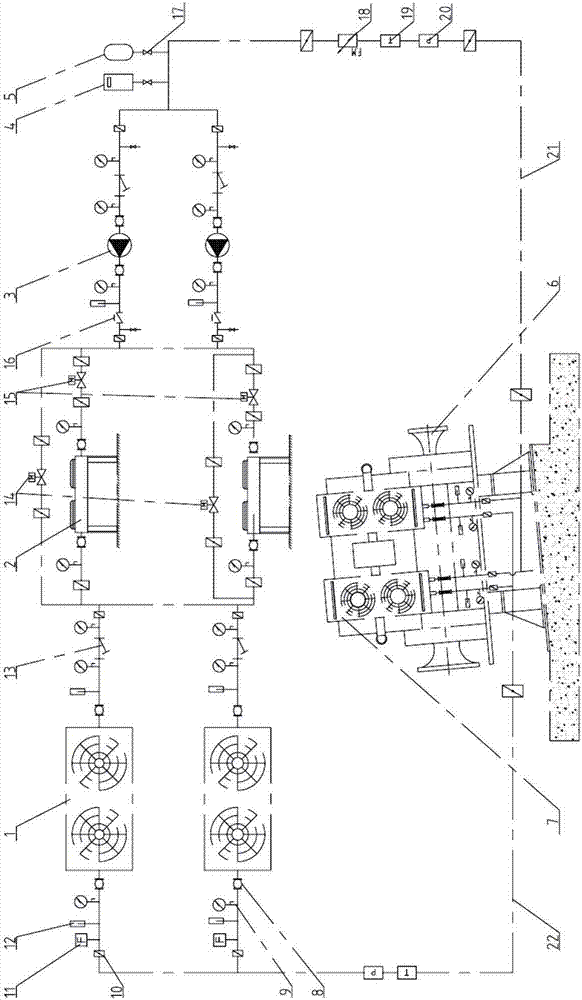

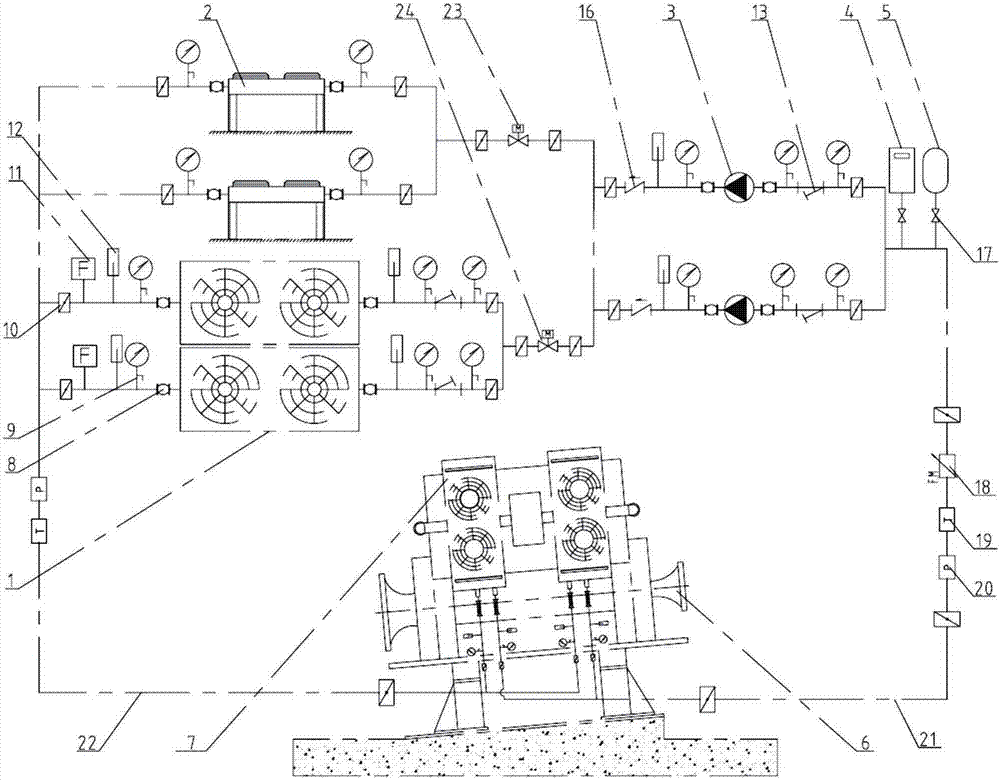

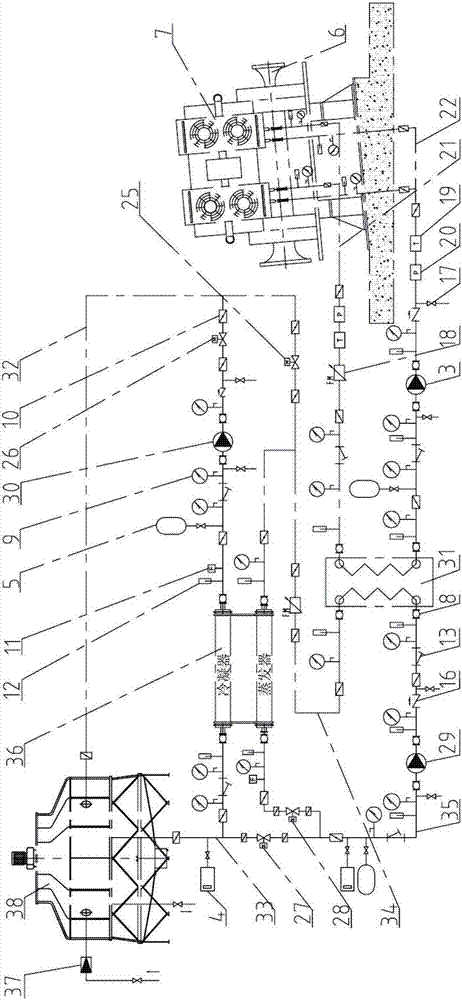

[0034] Since the traction motor is located on the ground, different from the cooling technology of the wind turbine, the design of the cooling system of the tractor does not need to consider a series of problems faced by the tested wind turbine after it goes to the sky. The cooling of the traction motor It will not be constrained by the environment faced by the wind turbines in the actual wind farm. Therefore, it is reasonable to apply the composite cooling technology which is easy to control and has higher efficiency to realize the cooling of the drag motor.

[0035] Cooling the drag motor itself usually uses an air-liquid heat exchange system. For the air-liquid heat exchange system, the air circulates through the drive motor to cool the internal parts of the drive motor, and then the hot air is converted into cold air through the air-liquid heat exchanger, while the coolant is in the air-liquid heat exchange The temperature in the container rises due to the heat exchange w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com