Novel peripheral driving mud scraper

A technology of peripheral transmission and mud scraper, which is applied to the feeding/discharging device, chemical instrument and method, and separation method of the settling tank, which can solve the problems of low reliability of mud scraping movement, poor mud scraping, large resistance, etc. problems, to achieve the effect of safe and reliable work, good effect and low moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

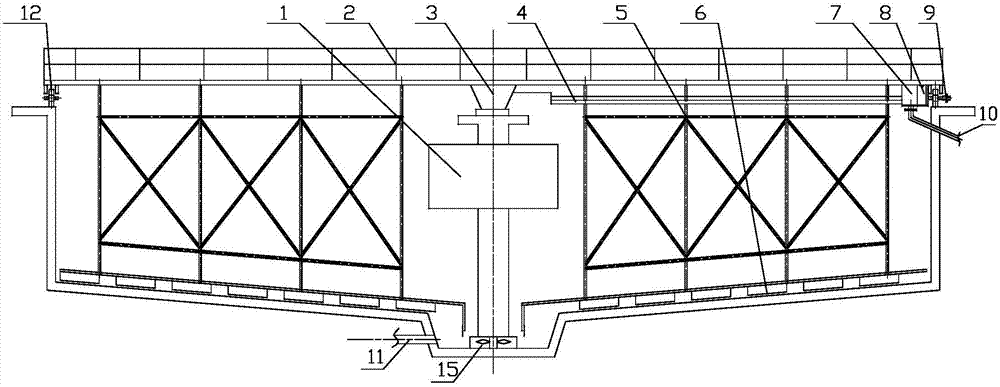

[0015] The present invention as Figure 1-3 As shown, the mud scraper includes a driving device 9 arranged on the periphery, a working bridge 2, a central support 3, a steady flow cylinder 1, a scraper 4, a mud scraper 6 and a weir 8, and the working bridge 2 passes through The driving device 9 is driven to rotate around the central support 3, and the lower part of the working bridge is provided with a running wheel 12 to move. The scraper 6 is arranged at the bottom of the sedimentation tank and connected to the working bridge 2 through the truss 5. The scraper 4 It is arranged at the lower part of the working bridge 2 and above the mud scraper 6;

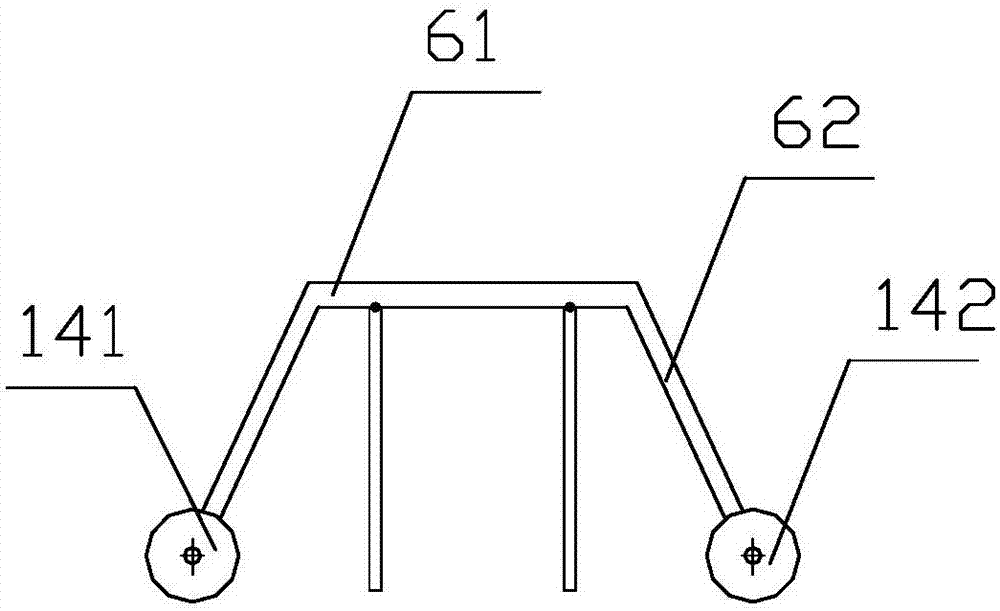

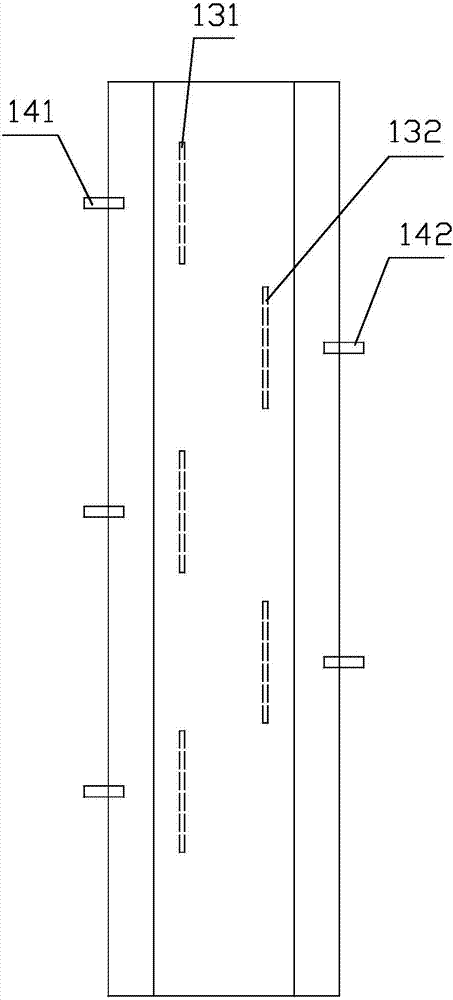

[0016] The mud scraper 6 includes a flat plate 61 and a pair of side plates 62. The pair of side plates 62 are arranged on both sides of the flat plate 61 and are respectively inclined towards the outside. The bottom surface of the flat plate is provided with two rows of parallel And the first plate body 131 and the second plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com