Hot melt glue gun

A hot-melt glue gun and hot-melt device technology are applied in the direction of coating, the device for coating liquid on the surface, etc., which can solve the problems of glue overflow and glue waste, and achieve simple and reasonable structure, convenient use, and heating. The effect of fast heating response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

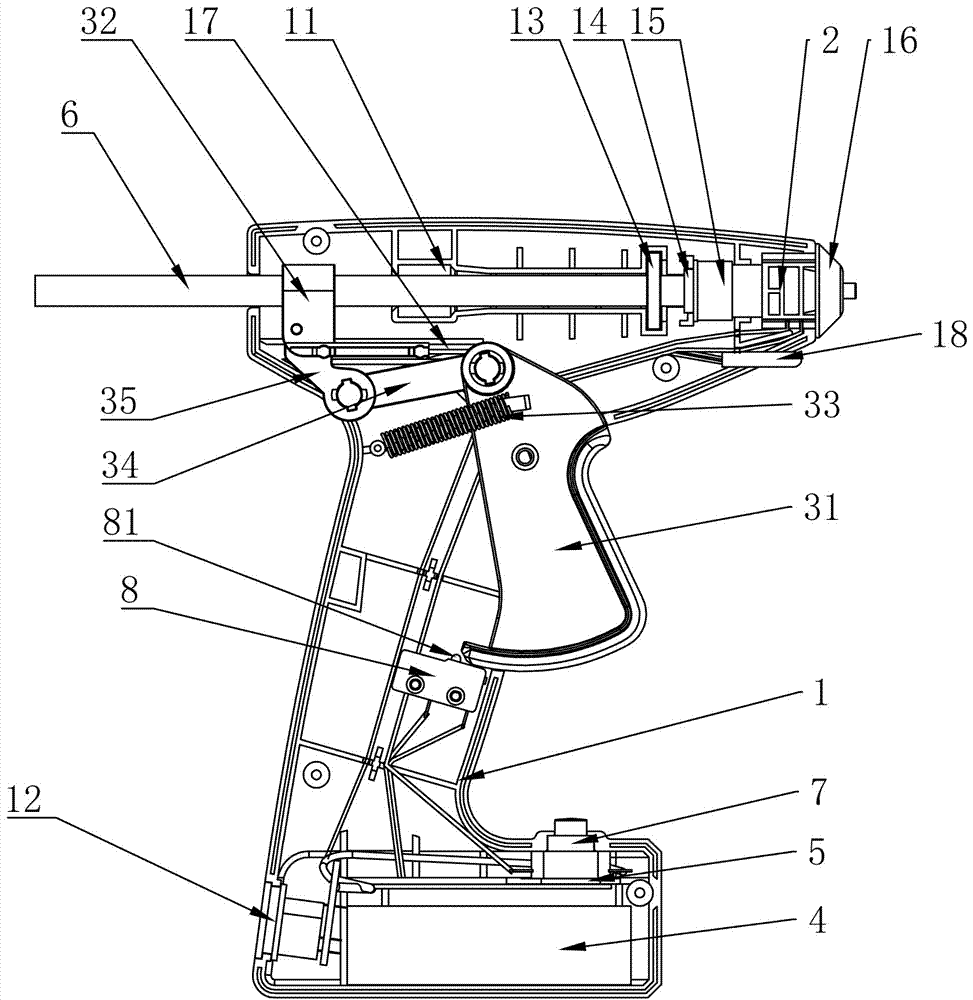

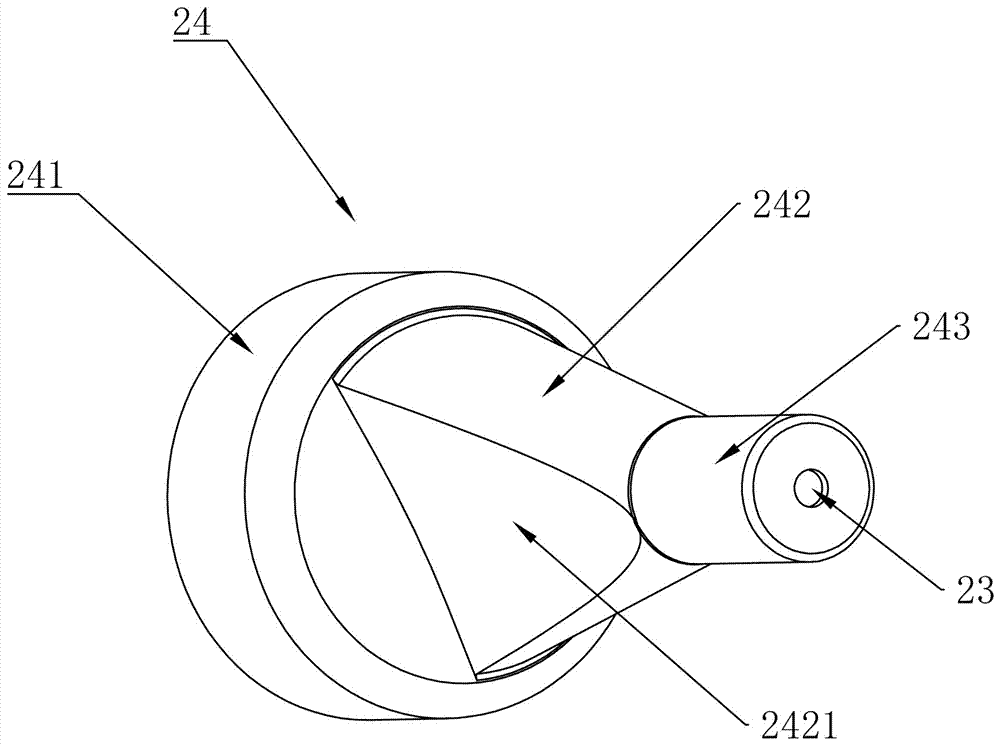

[0033] A hot melt glue gun, see figure 1 , 2 , 3, 4 and 7, including the gun body 1, the heating and melting device 2, the glue pushing mechanism 3, the power supply 4 and the circuit control board 5. Wherein, gun body 1 is provided with glue stick guide channel 11, and glue stick guide channel 11 is used for loading glue stick 6; Heating and melting device 2 is arranged in gun body 1, and heating and melting device 2 is provided with melting chamber 21. One end of the heating and hot melting device 2 is provided with a glue inlet 22, and the other end of the heating and hot melting device 2 is provided with a glue outlet 23, a glue stick guiding channel 11, a glue inlet 22, a melting cavity 21 and a glue outlet 23 are connected successively. Preferably, in this embodiment, the hole diameter of the glue outlet 23 is 0.5mm-1mm, which reduces the flow rate of the glue outlet, thereby playing an anti-overflow effect when the invention is in standby.

[0034] The glue pushing me...

Embodiment 2

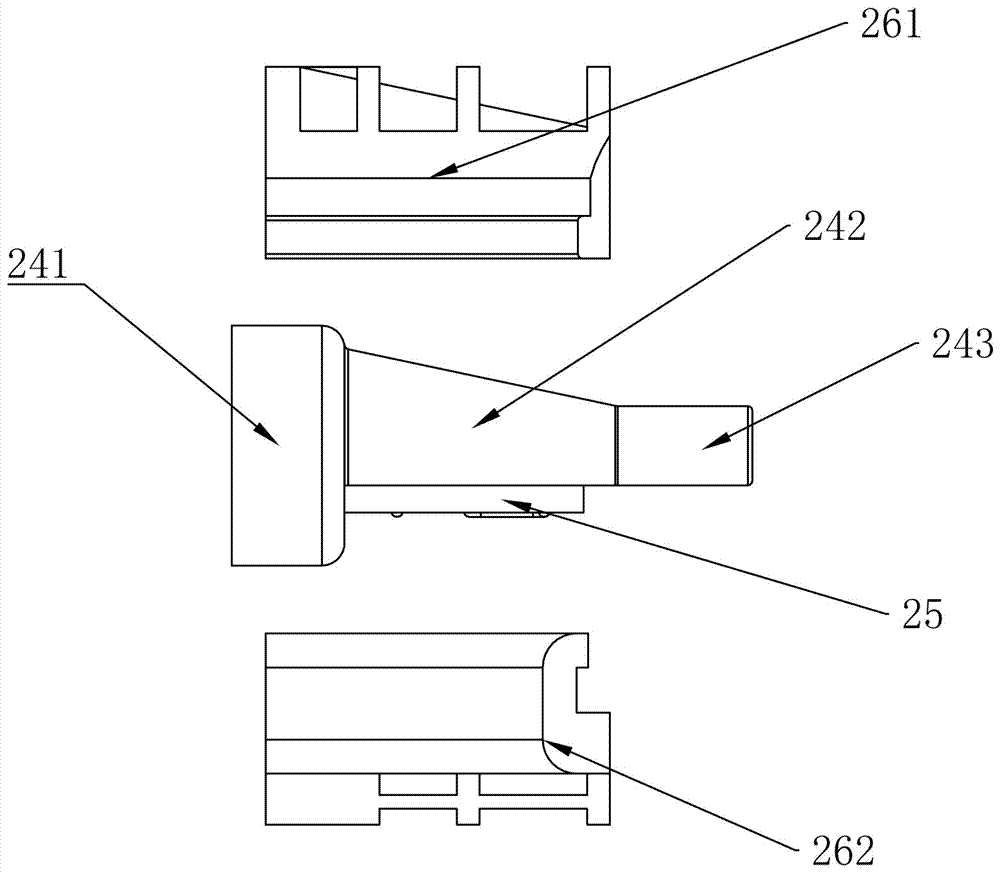

[0047] The main structure of this embodiment is the same as the main structure of the first embodiment above, the difference is: see Figure 5 , 6 Two straight walls 2421 are formed on the outer periphery of the tapered heating part 242 of the heating and melting device 2, and the two straight walls 2421 are arranged oppositely. Correspondingly, the number of heat generating sheets 25 is also set to two, and each heat The sheets 25 are all in close contact with the corresponding straight walls 2421 . In this embodiment, two straight walls 2421 are arranged on the outer periphery of the tapered heating part 242, so that the heating effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com