A kind of silicon/pedot composite material and preparation method thereof and application as negative electrode material of lithium ion battery

A composite material, aluminum-silicon alloy technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve the problems of poor cycle stability and poor conductivity, and achieve less electrode side reactions, good processing performance, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

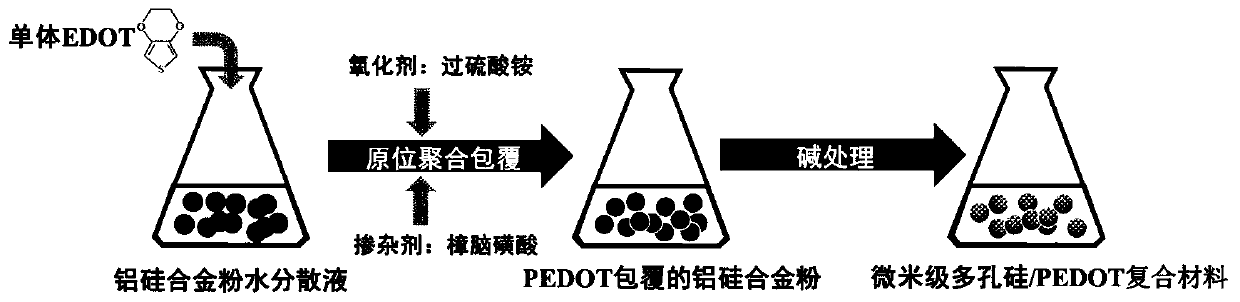

[0052] ①Take 1g of aluminum-silicon alloy powder (AlSi 10 ) into the reaction flask, then 90 mL of distilled water was added, and the solution was ultrasonicated for 10 min at room temperature.

[0053] ② Transfer the reaction vial to a magnetic stirrer, add 60 μL of 3,4-ethylenedioxythiophene (EDOT), and stir at room temperature for 10 min.

[0054] ③ Dissolve 0.12g of camphorsulfonic acid in 5mL of distilled water, drop it into the reaction bottle, and stir at room temperature for 10min.

[0055] ④ Dissolve 0.6 g of ammonium persulfate in 5 mL of distilled water, drop it into a reaction bottle, react at room temperature for 24 hours, separate and dry to obtain a PEDOT-coated aluminum-silicon alloy.

[0056] ⑤Take 1g of synthesized AlSi 10 / PEDOT powder added to 0.5mol L -1 Sodium hydroxide solution was mixed and reacted at 60°C for 2 hours, separated and dried to obtain Si / PEDOT.

[0057] ⑥ Dissolve 15mg of Na-CMC in 2mL of deionized water and stir at room temperature fo...

Embodiment 2

[0061] ①Take 1g of AlSi with a particle size of 5μm 10 Add to the reaction bottle, then add 90mL of distilled water, and sonicate at room temperature for 10min.

[0062] ② Transfer the reaction vial to a magnetic stirrer, add 120 μL of 3,4-ethylenedioxythiophene (EDOT), and stir at room temperature for 10 min.

[0063] ③ Dissolve 0.12g of camphorsulfonic acid in 5mL of distilled water, drop it into the reaction bottle, and stir at room temperature for 10min.

[0064] ④ Dissolve 0.6 g of ammonium persulfate in 5 mL of distilled water, drop it into a reaction bottle, react at room temperature for 24 hours, separate and dry to obtain a PEDOT-coated aluminum-silicon alloy.

[0065] ⑤Take 1g of synthesized AlSi 10 / PEDOT powder added to 0.5mol L -1 Sodium hydroxide solution was mixed and reacted at 60°C for 2 hours, separated and dried to obtain Si / PEDOT.

[0066] ⑥ Dissolve 15mg of Na-CMC in 2mL of deionized water and stir at room temperature for 4h.

[0067] ⑦ Grind and mix ...

Embodiment 3

[0070] ①Take 1g of AlSi with a particle size of 5μm 10 Add to the reaction bottle, then add 90mL of distilled water, and sonicate at room temperature for 10min.

[0071] ② Transfer the reaction vial to a magnetic stirrer, add 180 μL of 3,4-ethylenedioxythiophene (EDOT), and stir at room temperature for 10 min.

[0072] ③ Dissolve 0.12g of camphorsulfonic acid in 5mL of distilled water, drop it into the reaction bottle, and stir at room temperature for 10min.

[0073] ④ Dissolve 0.6 g of ammonium persulfate in 5 mL of distilled water, drop it into a reaction bottle, react at room temperature for 24 hours, separate and dry to obtain a PEDOT-coated aluminum-silicon alloy.

[0074] ⑤Take 1g of synthesized AlSi 10 / PEDOT powder added to 0.5mol L -1 Sodium hydroxide solution was mixed and reacted at 60°C for 2 hours, separated and dried to obtain Si / PEDOT.

[0075] ⑥ Dissolve 15mg of Na-CMC in 2mL of deionized water and stir at room temperature for 4h.

[0076] ⑦ Grind and mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com