Bell cup or atomizer ring comprising an insulating coating

A technology of air rings and bell cups, applied in coatings, devices for coating liquid on surfaces, electrostatic spray devices, etc., can solve problems such as high risk of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

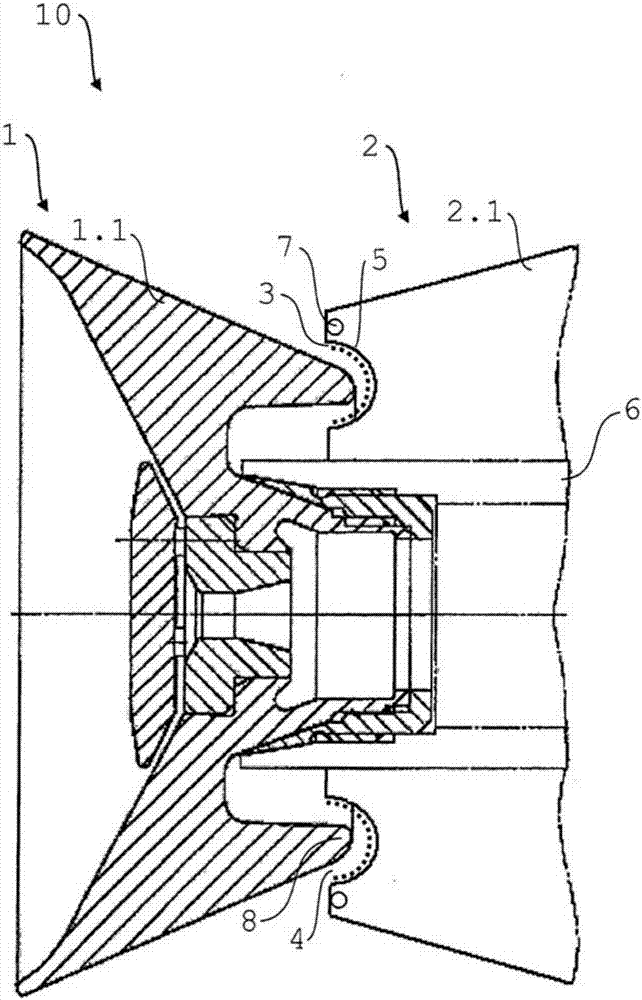

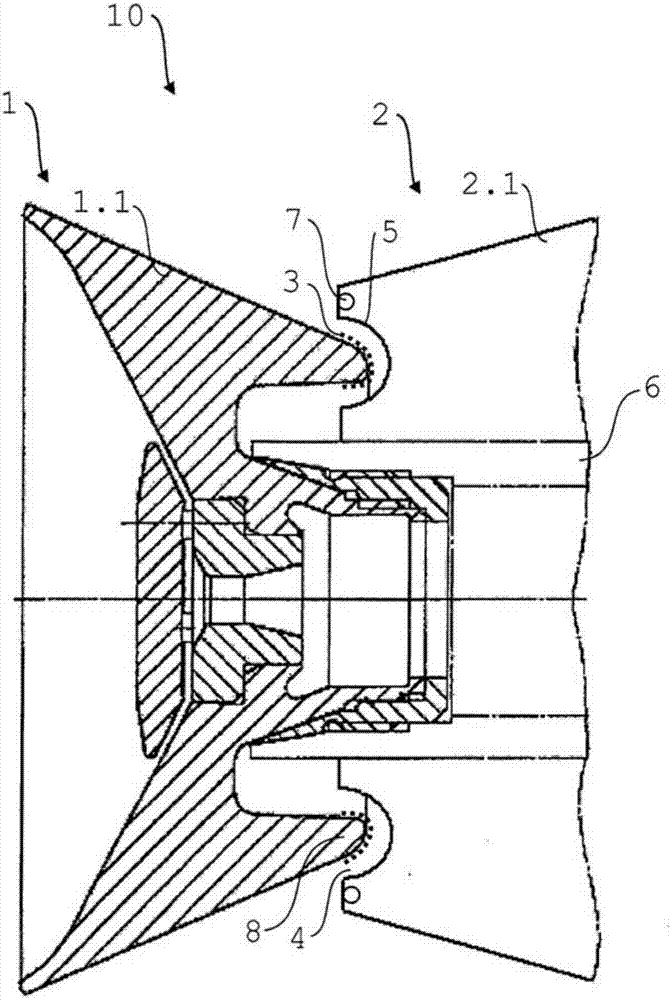

[0079] The exemplary embodiments shown in the figures partially overlap so that, for the sake of illustration, similar or identical parts bear the same reference numerals, and reference is also made to the description of the other exemplary embodiments in order to avoid repetitions.

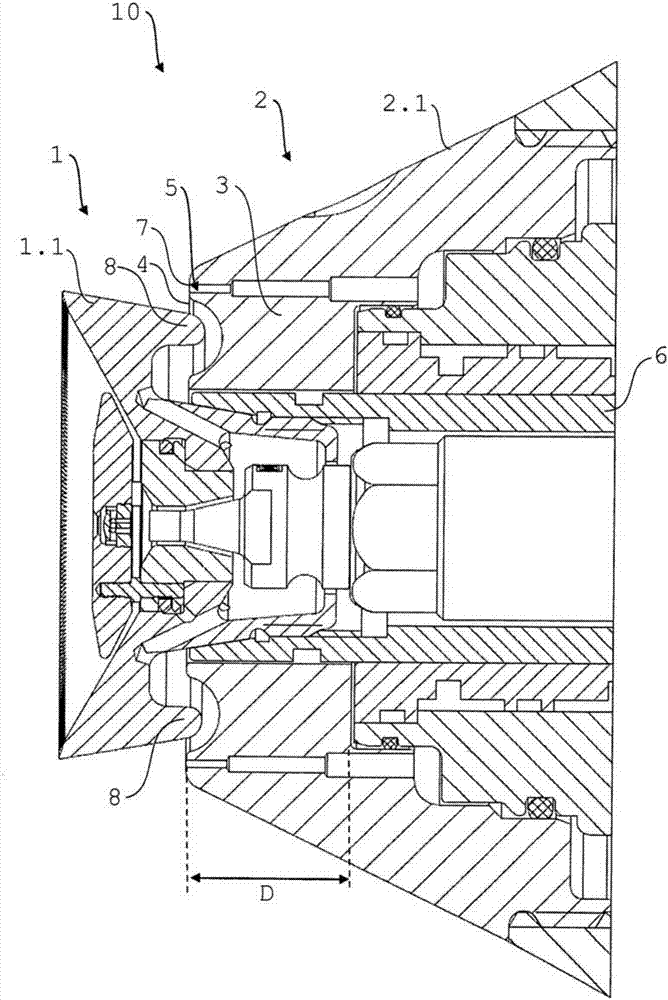

[0080] figure 1 is a sectional view of an electrostatic rotary atomizer 10 for painting motor vehicle bodies and / or additional parts thereof. The rotary atomizer 10 comprises a bell cup 1 for atomizing lacquer and for delivering a spray jet of lacquer, the bell cup 1 rotating during operation. The rotary atomizer 10 also comprises a pilot-air ring 2 for delivering a pilot-air flow from the pilot-air outlet 7 to shape the spray jet of paint delivered through the bell cup 1, during operation the pilot-air ring 2 Does not rotate. The bell cup 1 is arranged in front of the guide air ring 2 . The guide-air ring 2 corresponds to an embodiment of the invention, while the bell cup 1 can be designed su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com