Intrinsically safe oil-resistant and mud-resistant fire-resistant cable for offshore platforms and its preparation process

An intrinsically safe, fire-resistant cable technology, applied in the direction of cable/conductor manufacturing, insulated cables, cables, etc., can solve the problems of increasing oil and gas explosions, cable overload, etc., to achieve the ideal ability to prevent sparks, resist electric field coupling, and resist electromagnetic field interference ideal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

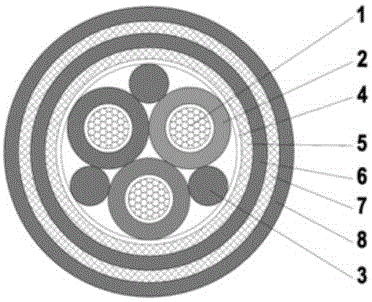

[0026] Such as figure 1 The shown is an intrinsically safe oil-resistant and mud-resistant fire-resistant cable for offshore platforms. The cable is sequentially provided with a cable core wrapped by a low-smoke, halogen-free oxygen barrier tape 4, annealed and tinned Cable shielding layer 5 braided by annealed copper wire, inner lining layer 6 extruded by low-smoke halogen-free polyolefin, armor layer 7 braided by annealed tinned annealed copper wire, low-smoke halogen-free polyolefin The outer sheath 8 is made of flame-retardant, oil-resistant and mud-resistant cross-linked polyolefin extruded, and the cable core wrapping layer 4 is also equipped with a refractory conductor 1 using Type 6 annealed tinned copper. At the same time, the refractory conductor is wrapped with two layers of High-temperature calcined mica tape, insulating layer 2 and filler 3 on the outer layer of refractory conductor 1, insulating layer 2 is extruded from low-smoke halogen-free ethylene-propylene r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com