Compressor housing for supercharger and manufacturing method thereof

A technology for compressor housings and manufacturing methods, applied to machines/engines, parts of pumping devices for elastic fluids, mechanical equipment, etc., can solve problems such as damage to impellers, prevent the decline in compression efficiency, and maintain force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

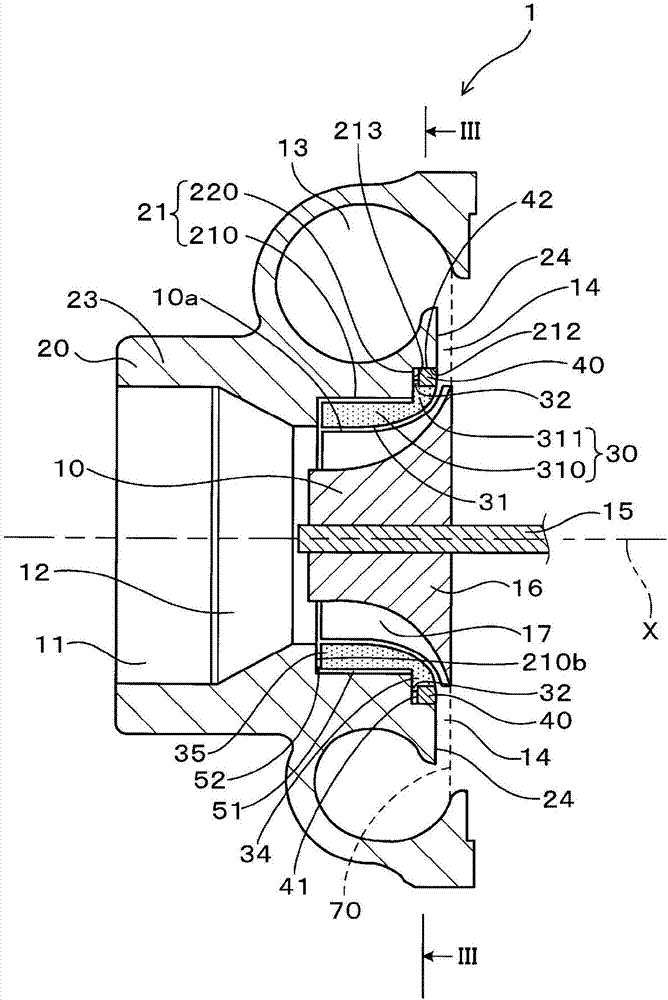

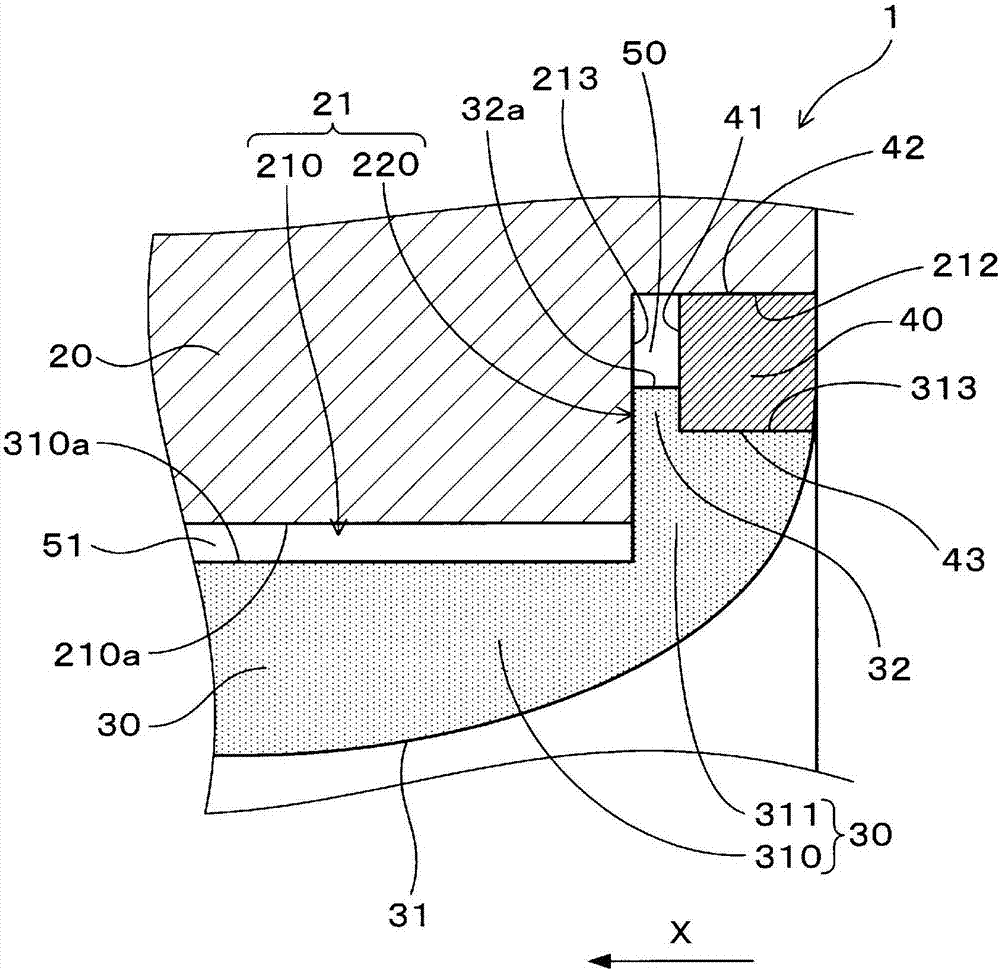

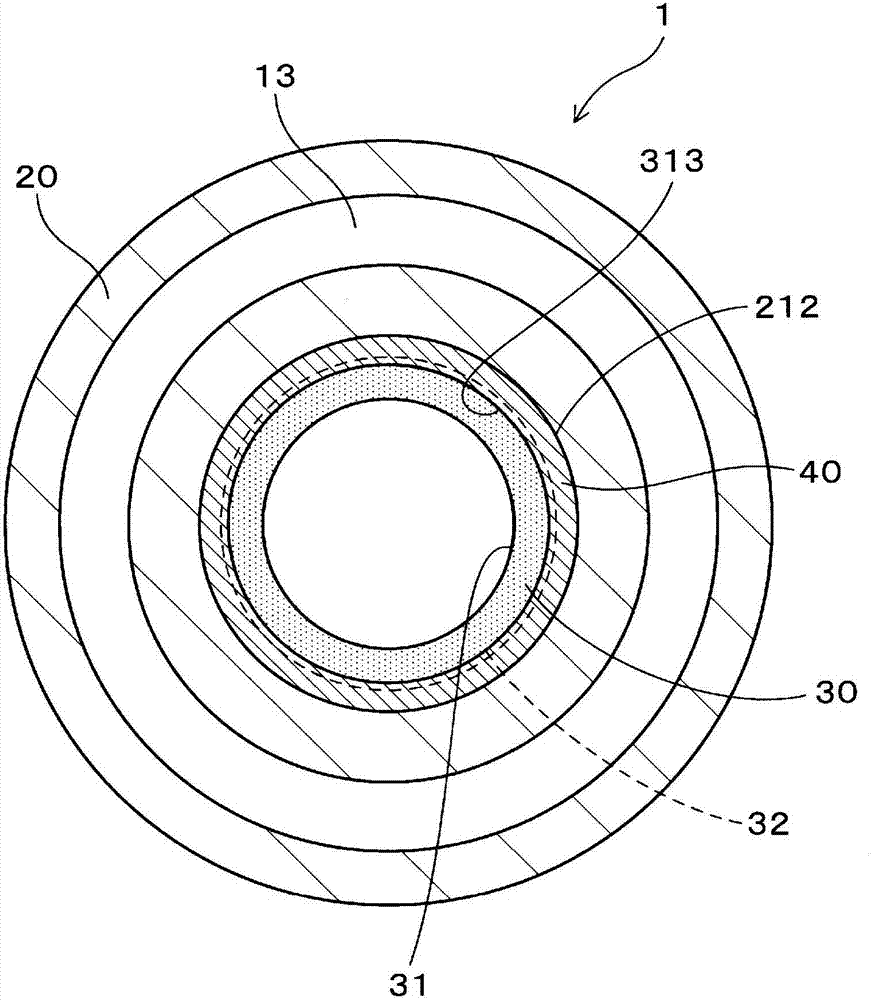

[0053] use Figure 1 to Figure 9 The compressor casing for the supercharger of this example will be described.

[0054] Such as figure 1 As shown, the compressor housing 1 for a supercharger of this example (hereinafter also referred to as “compressor housing 1 ”) includes a housing main body 20 , a slide member 30 , and a ring-shaped member 40 .

[0055] The casing main body 20 is configured to accommodate the impeller 10 , and has a concave inner peripheral recess 21 formed on an annular inner peripheral surface along the outer periphery 10 a of the impeller 10 .

[0056] The sliding member 30 is formed in an annular shape and is disposed in the inner peripheral recess 21 , and its inner peripheral surface forms a shroud surface 31 facing the impeller 10 .

[0057] The ring member 40 is formed in a ring shape along the inner peripheral recess 21 of the casing body 20 , and is press-fitted into the inner peripheral recess 21 along the axial direction X of the impeller 10 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com