Bearing device of compressor for refrigerator

A bearing device, refrigerator technology, applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve problems such as seizure, narrow bearing sliding surface and crankshaft surface, and reduced compression efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

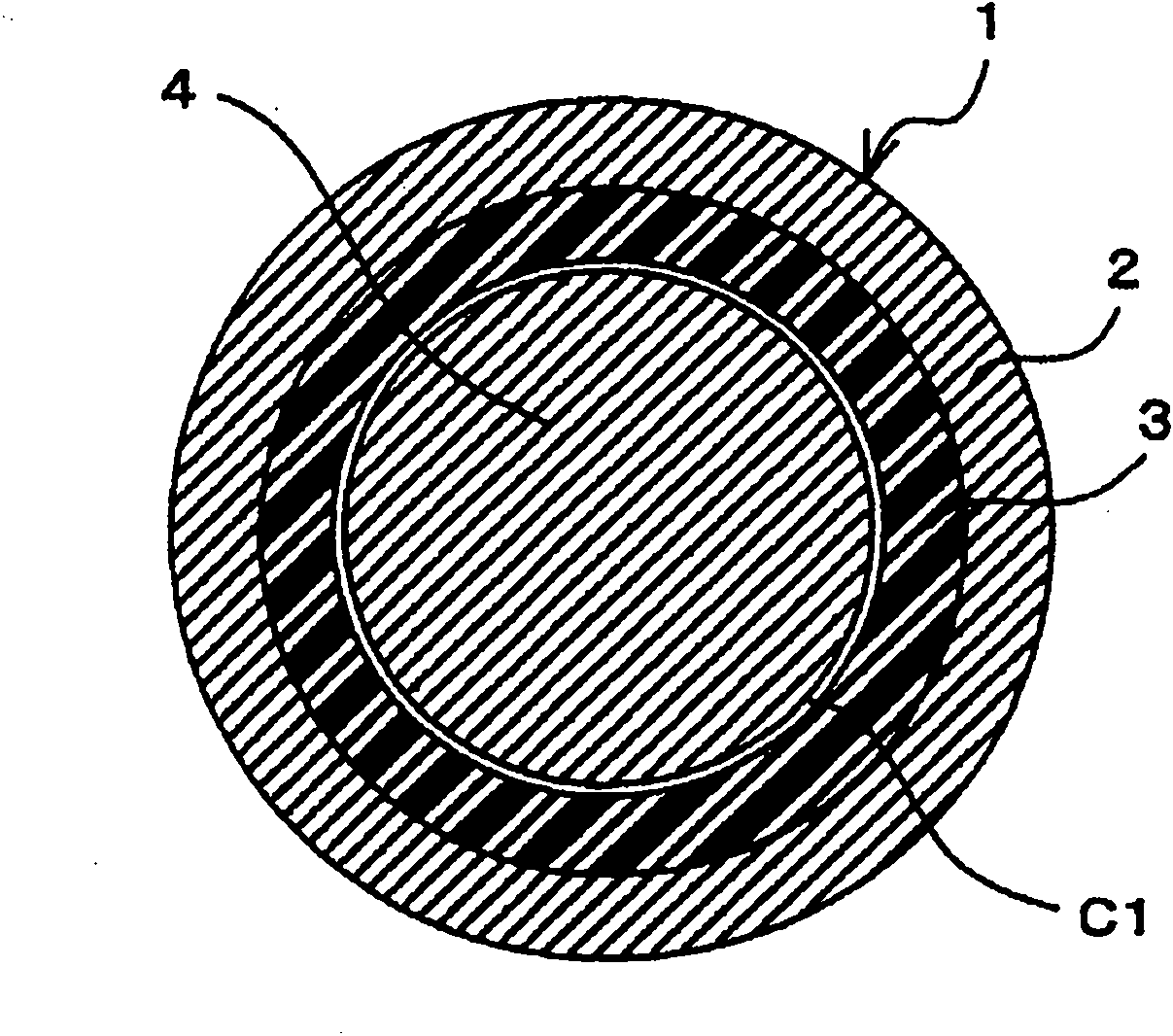

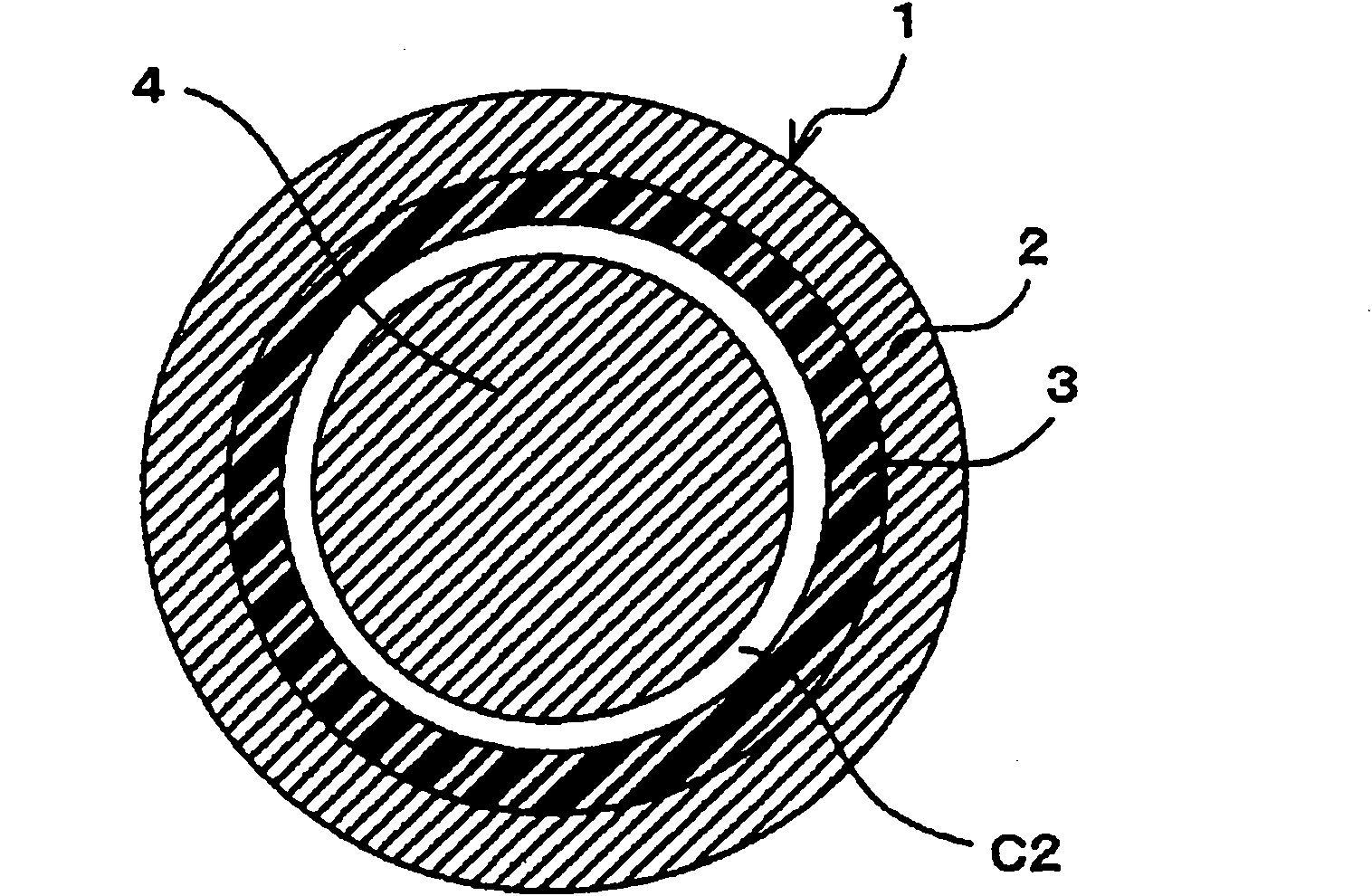

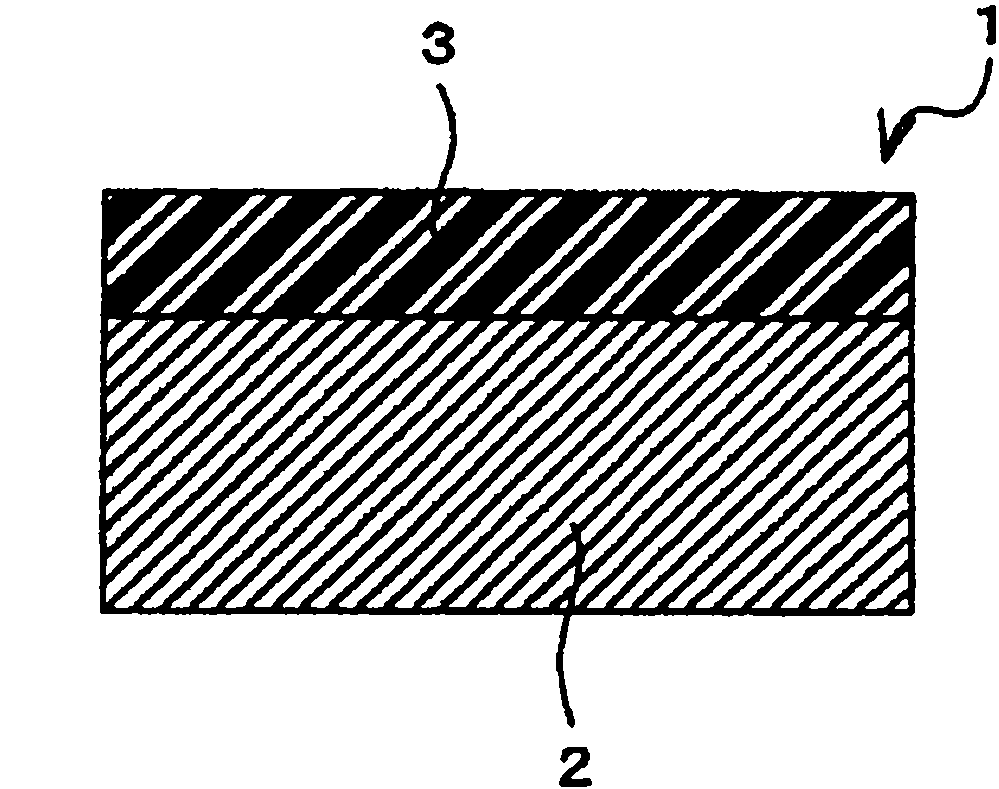

[0029] A description will be given below of an embodiment according to the present invention with reference to FIGS. 1 to 3 . Figure 1A is a cross-sectional view showing the relationship between crankshaft 4 and bearing 1 during normal operation of the compressor in refrigerant, Figure 1B is a sectional view showing the relationship between the crankshaft 4 and the bearing 1 at the start of the compressor in the refrigerant, figure 2 is a schematic cross-sectional view of a bearing 1 in which the resin sliding layer 3 is coated directly on the steel backing layer 2, and image 3 is a schematic cross-sectional view of a bearing 1 in which a porous metal sintered layer 5 is formed as an intermediate layer on a steel back layer 2 and a resin sliding layer 3 is coated on the porous metal sintered layer 5 . In this case, the above-mentioned drawings are schematic diagrams of the crankshaft 4 and the bearing 1 according to this embodiment, and each part is drawn exaggeratedly or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com