Method for fixing tea leaves

A technology for tea and greening, applied in the direction of tea processing before extraction, can solve the problems of great influence on tea quality, and achieve the effects of reducing labor intensity, good color and simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

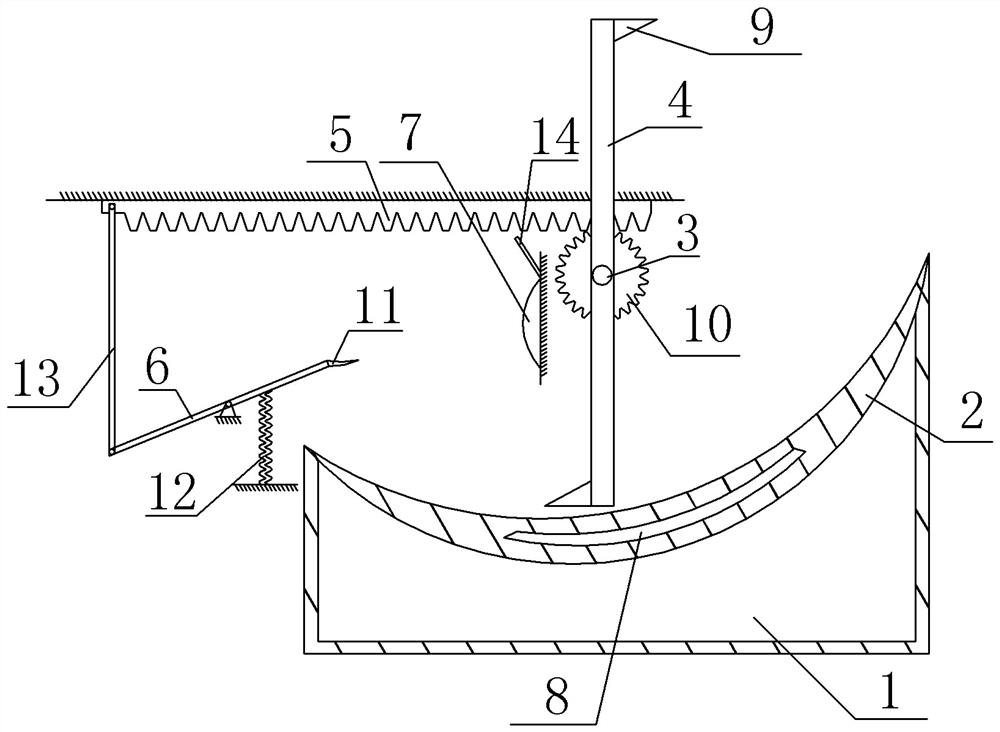

[0021] The reference signs in the drawings of the description include: stove 1, frying pan 2, support rod 3, stirring rod 4, rack 5, tea throwing rod 6, impact plate 7, cavity 8, shovel pressing block 9, gear 10, Shovel block 11, stage clip 12, connecting rod 13, baffle plate 14.

[0022] The method that is used for tea leaves fixing, adopts such as figure 1 The shown tea greening device includes a stove 1, a frying pan 2, a servo motor, a support rod 3, a stirring rod 4, a rack 5, a tea throwing rod 6 and an impact plate 7. The frying pan 2 is obliquely fixed on the stove 1, with the opposite side of the attached drawing as the front, the frying pan 2 is lower on the left and higher on the right; The servo motor is fixed on the frame above the frying pan 2, the output shaft of the servo motor is horizontally backward, and the support rod 3 is fixed at the rear end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com