Preparation method of forming paper for preparing hybrid heat-not-burn cigarette core

A technology of heat-not-burn and forming paper, which is applied in the fields of application, tobacco, and smoker's products, and can solve the problem of not developing a hybrid heat-not-burn cigarette core and its related products, so as to achieve good application prospects and improve smoke Quantity, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

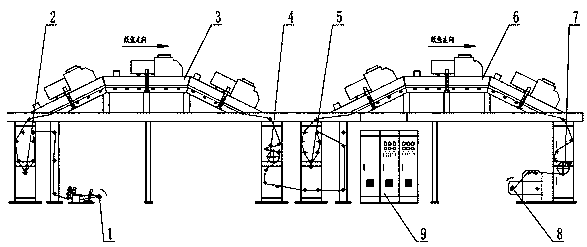

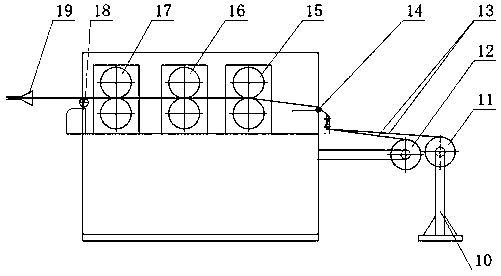

Image

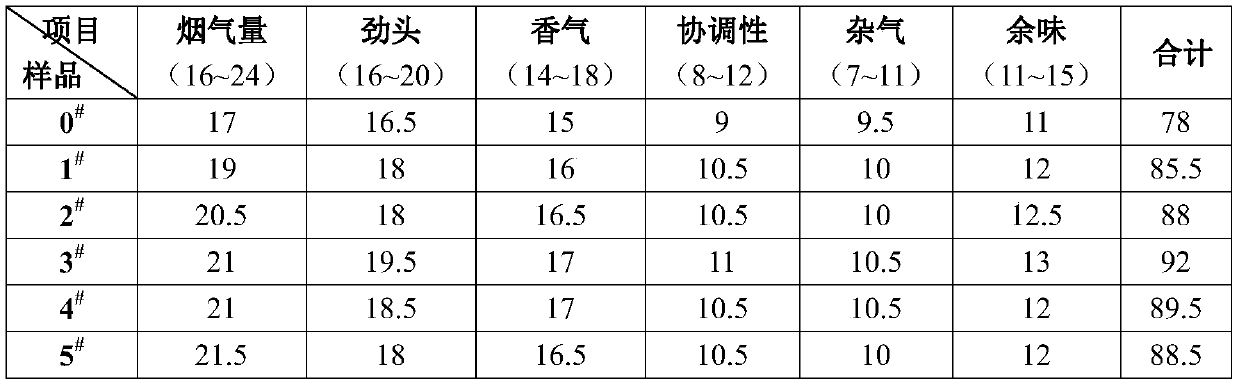

Examples

Embodiment 1

[0051] A preparation method for forming paper for preparing hybrid heat-not-burn cigarette cores, comprising the following steps:

[0052] Step (1), pretreatment: performing microwave expansion pretreatment on Burley tobacco stems until the expansion rate is 200-260%, and then crushing and screening the obtained expanded Burley tobacco stems and the upper tobacco leaves of Burley tobacco to 80-120 meshes to obtain Burley tobacco expanded tobacco stem particles and Burley tobacco leaf particles;

[0053] Step (2), preparation of the first mixture: After mixing the Burley tobacco expanded tobacco stem particles and the Burley tobacco leaf particles according to a mass ratio of 6:4, add a smoke-generating agent therein, stir until the mixture is uniform, and then statically Set for 0.5h to obtain the first mixture;

[0054] The added mass of the smoke-generating agent is 1 time of the total mass of the Burley tobacco expanded tobacco stem particles and the Burley tobacco leaf pa...

Embodiment 2

[0073] A preparation method for forming paper for preparing hybrid heat-not-burn cigarette cores, comprising the following steps:

[0074] Step (1), pretreatment: performing microwave expansion pretreatment on Burley tobacco stems until the expansion rate is 200-260%, and then crushing and screening the obtained expanded Burley tobacco stems and the upper tobacco leaves of Burley tobacco to 80-120 meshes to obtain Burley tobacco expanded tobacco stem particles and Burley tobacco leaf particles;

[0075] Step (2), preparation of the first mixture: After mixing the Burley expanded tobacco stem particles and the Burley tobacco leaf particles uniformly according to the mass ratio of 4:6, adding a smoking agent thereinto, stirring until uniformly mixed, and then statically Set for 1.5h to obtain the first mixture;

[0076] The added quality of the smoke-generating agent is twice the total mass of the Burley tobacco expanded tobacco stem particles and the Burley tobacco leaf partic...

Embodiment 3

[0099] A preparation method for forming paper for preparing hybrid heat-not-burn cigarette cores, comprising the following steps:

[0100] Step (1), pretreatment: performing microwave expansion pretreatment on Burley tobacco stems until the expansion rate is 200-260%, and then crushing and screening the obtained expanded Burley tobacco stems and the upper tobacco leaves of Burley tobacco to 80-120 meshes to obtain Burley tobacco expanded tobacco stem particles and Burley tobacco leaf particles;

[0101] The specific method for performing microwave expansion pretreatment on Burley tobacco stems to an expansion rate of 200-260% is as follows: put Burley tobacco stems with a moisture content of 14-16% into a microwave expansion device, and the microwave expansion parameter is The frequency is 2450M Hz, the power is 900W, and the time is 20s; the expanded tobacco stems of the required Burley tobacco have no obvious charring phenomenon;

[0102] Step (2), preparation of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com