End plug clamping head

A collet, consistent technology, applied in resistance welding equipment, welding equipment, metal processing equipment and other directions, can solve problems such as deformation, and achieve the effect of large welding surface, not easy to fall off, and good stable locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

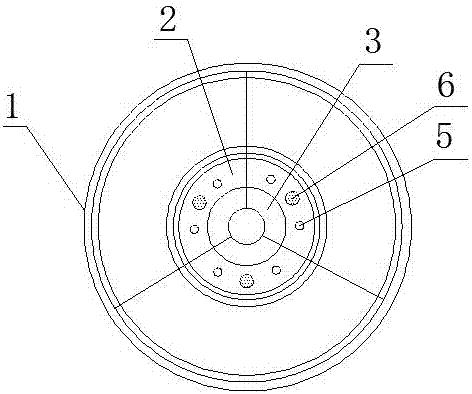

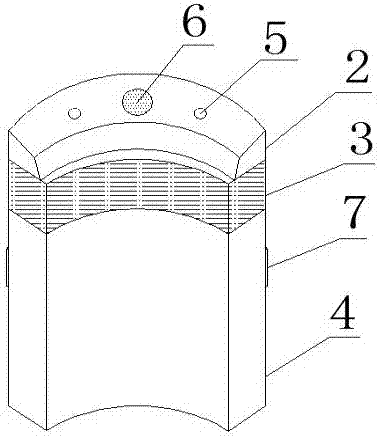

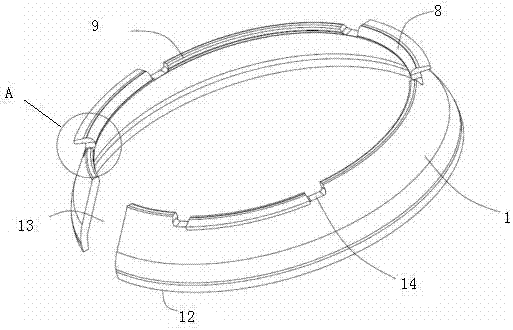

[0031] Such as Figure 1-4 As shown, in order to make the object, technical solution and beneficial effect of the present invention clearer, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to facilitate the understanding of technical personnel.

[0032] An end plug chuck, including a chuck body and a fixing ring 1, the fixing ring 1 is sleeved on the outer wall of the chuck body, the chuck body includes three chuck units, and the three chuck units are combined into a cylindrical chuck The head body, the end plug chuck of the present invention, adopts the eddy current formed by low resistance and high current, so that both the end plug and the cladding tube are welded in a molten state (that is, the critical point of melting, but not melted) and rapidly cooled ; The use of the end plug chuck of the invention can make the welded workpiece not deformed and discolored, and the metallographic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com