Noiseless winch

A winch and silent technology, which is applied in hoisting devices, clockwork mechanisms, etc., can solve problems such as unsafe, unenvironmental protection, loud noise, etc., achieve sufficient control, ensure stability, and reduce noise pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be clearly and completely described below through specific embodiments in conjunction with the accompanying drawings.

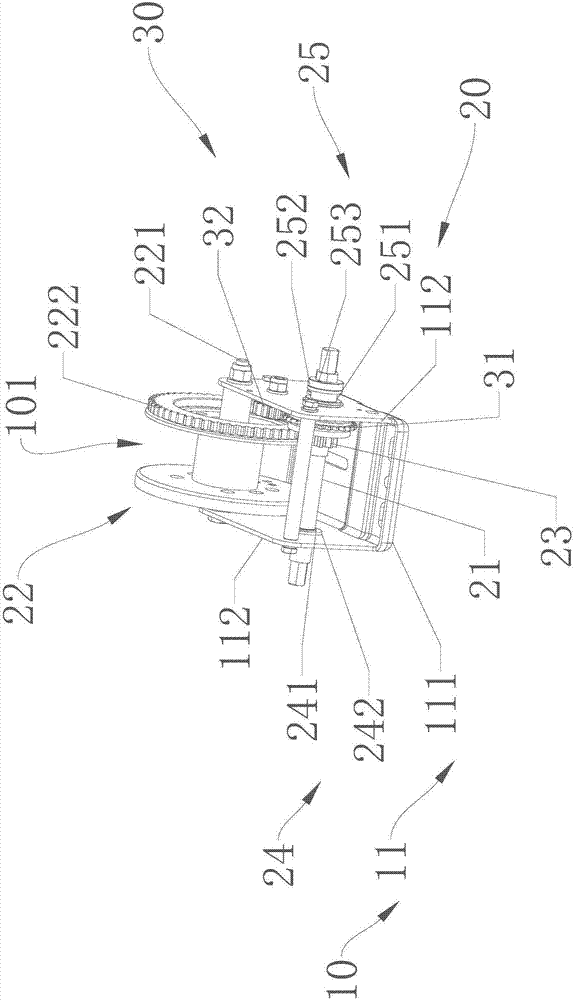

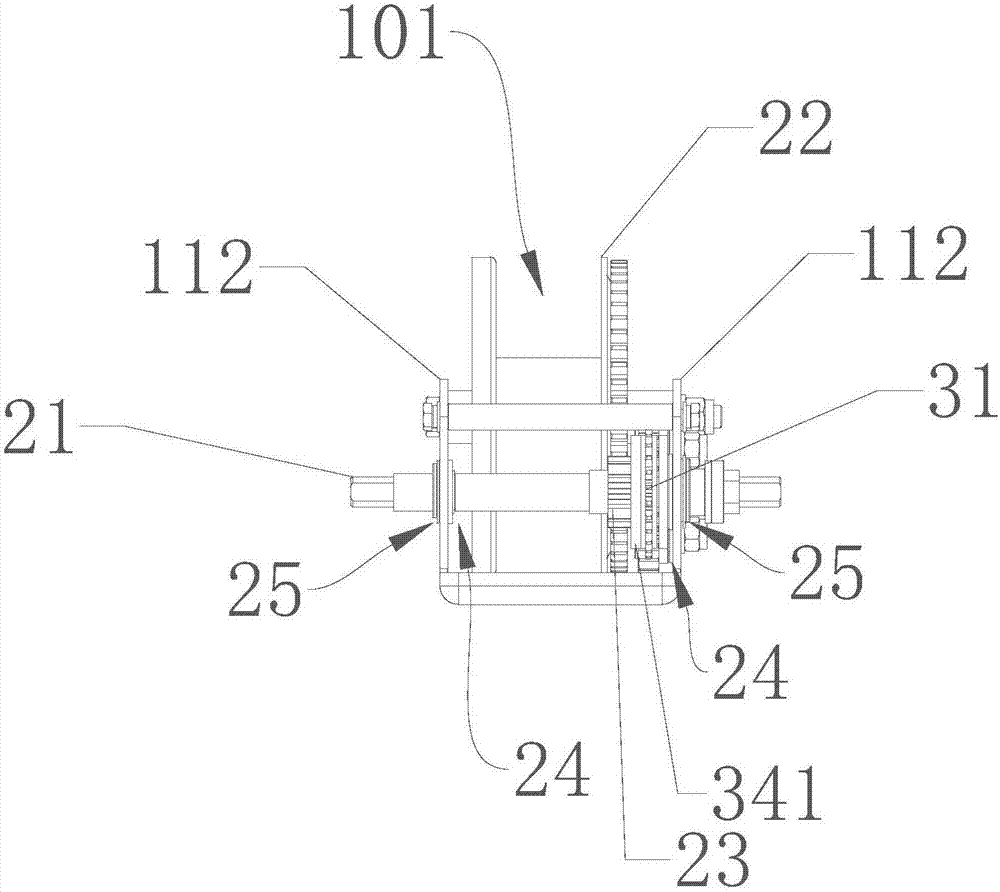

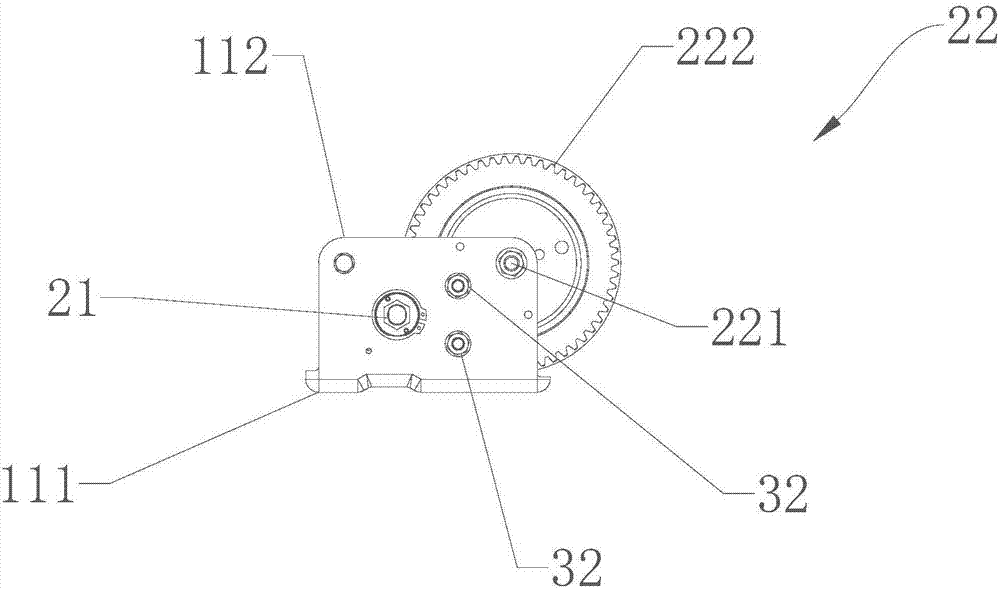

[0027] refer to Figure 1 to Figure 3 , The present invention provides a silent winch, which can be used to lift or pull heavy objects by retracting and retracting steel wire ropes or chains. This application document takes the operation of retracting and retracting steel wire ropes as an example to illustrate the structure and principle of the silent winch. The silent winch includes a supporting system 10 , a transmission system 20 and a braking system 30 . The supporting system 10 is used as the supporting structure of the entire silent winch for supporting the silent winch. The transmission system 20 is arranged on the support system 10 to be operated to realize the rope receiving or releasing operation. The braking system 30 is disposed on the support system 10 and is used for braking to stop ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com