Pipeline detecting robot and detecting method thereof

A pipeline inspection and robot technology, which is applied to special pipes, pipe components, mechanical equipment, etc., can solve problems such as pipe diameters that cannot adapt to large-scale changes, the camera shooting height cannot be adjusted, and the image shooting effect is affected, so as to reduce labor costs. Work volume, automatic turning and azimuth adjustment, and the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

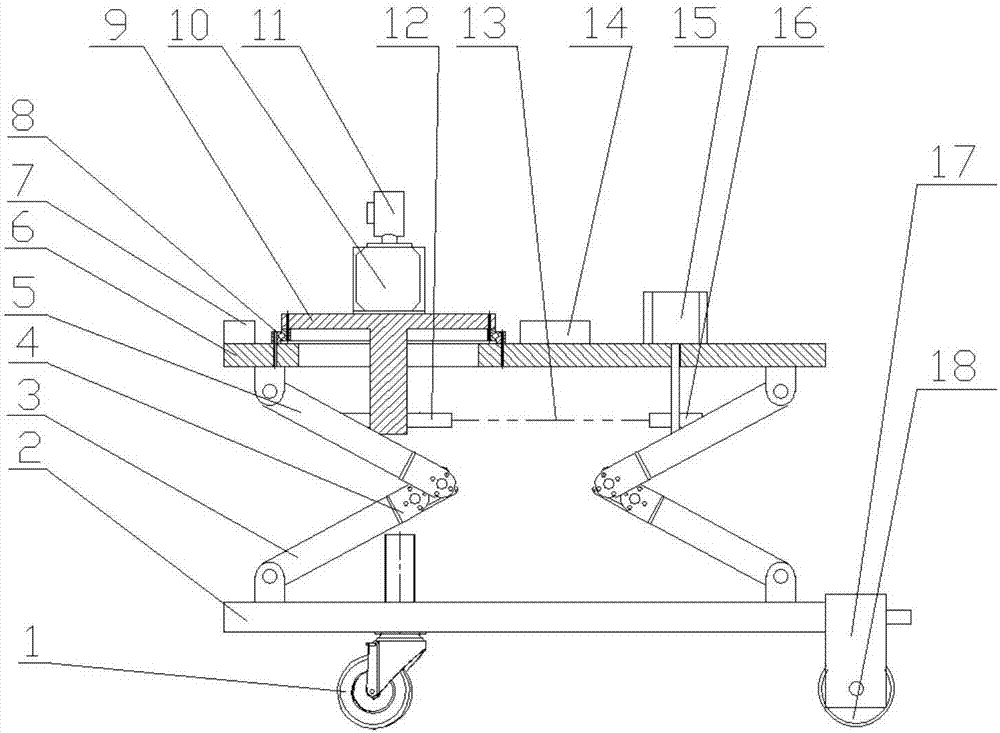

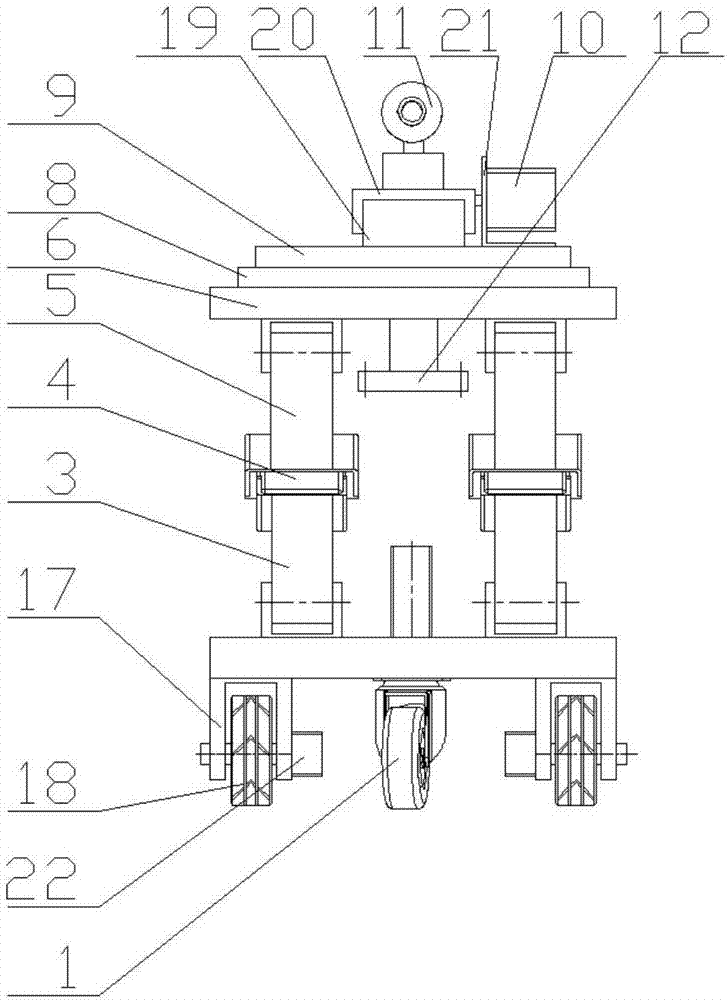

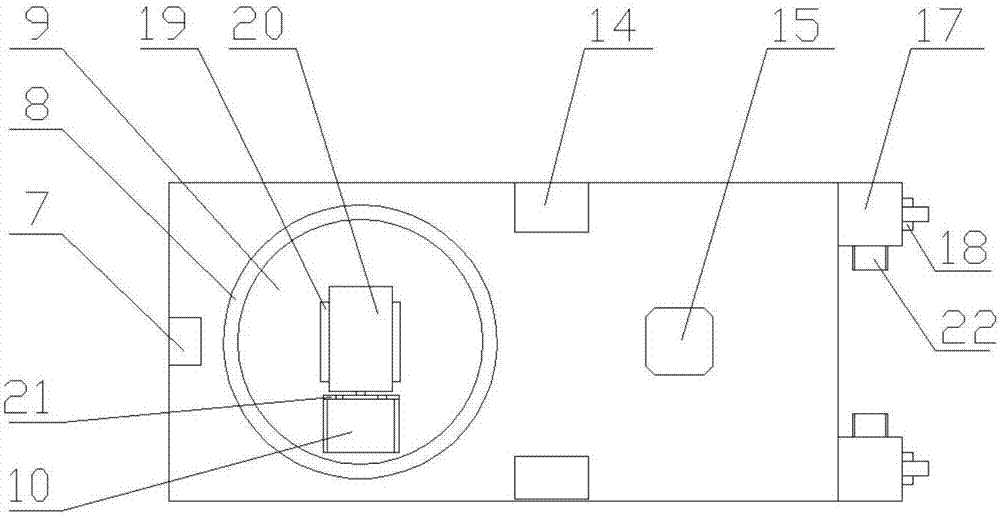

[0046] Such as Figure 1 to Figure 3 As shown, a pipeline detection robot includes: a moving component, a lifting component, a horizontal rotation component, a pitching component, a longitudinal ranging sensor, a lateral ranging sensor and a camera.

[0047] The pipeline inspection robot can move in the pipeline and take images inside the pipeline. When the robot is moving in the pipeline, it can turn automatically. During the pipeline image capture process, the camera can be adjusted in height, left and right angles and pitch angles.

[0048] Such as Figure 4 to Figure 5 As shown, the moving assembly includes a steering wheel 1 , a first support platform 2 , a wheel frame 17 , a driving wheel 18 and a wheel driving mechanism 22 . The movement component is responsible for the movement of the robot within the pipeline.

[0049] Such as Im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com