A wire stripping machine integrating stripping, bending and capping

A wire stripping machine and integrated technology, which is applied in the direction of dismantling/armouring cable equipment, cable installation, cable installation device, etc., can solve the problems of low work efficiency, heavy labor, slow installation speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

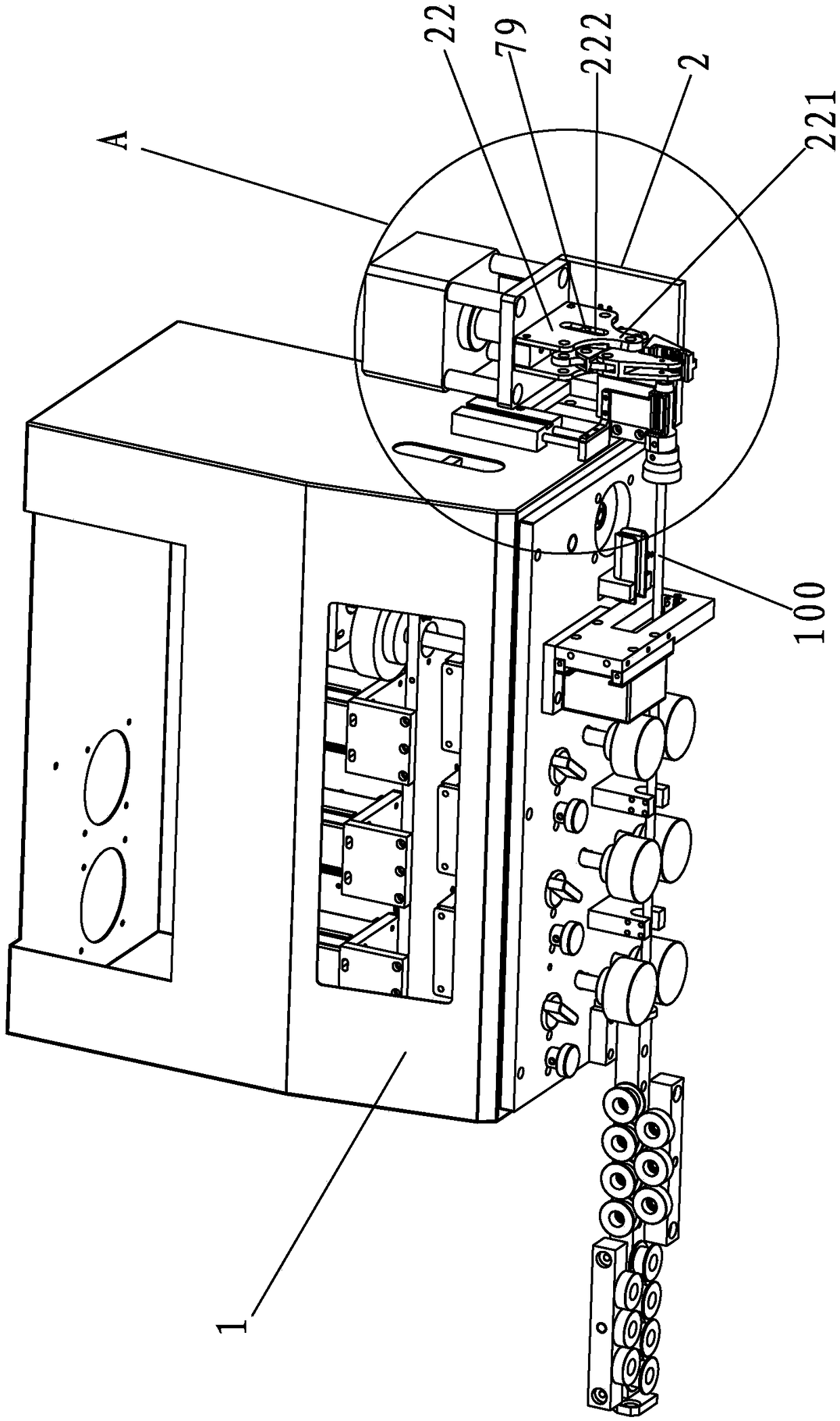

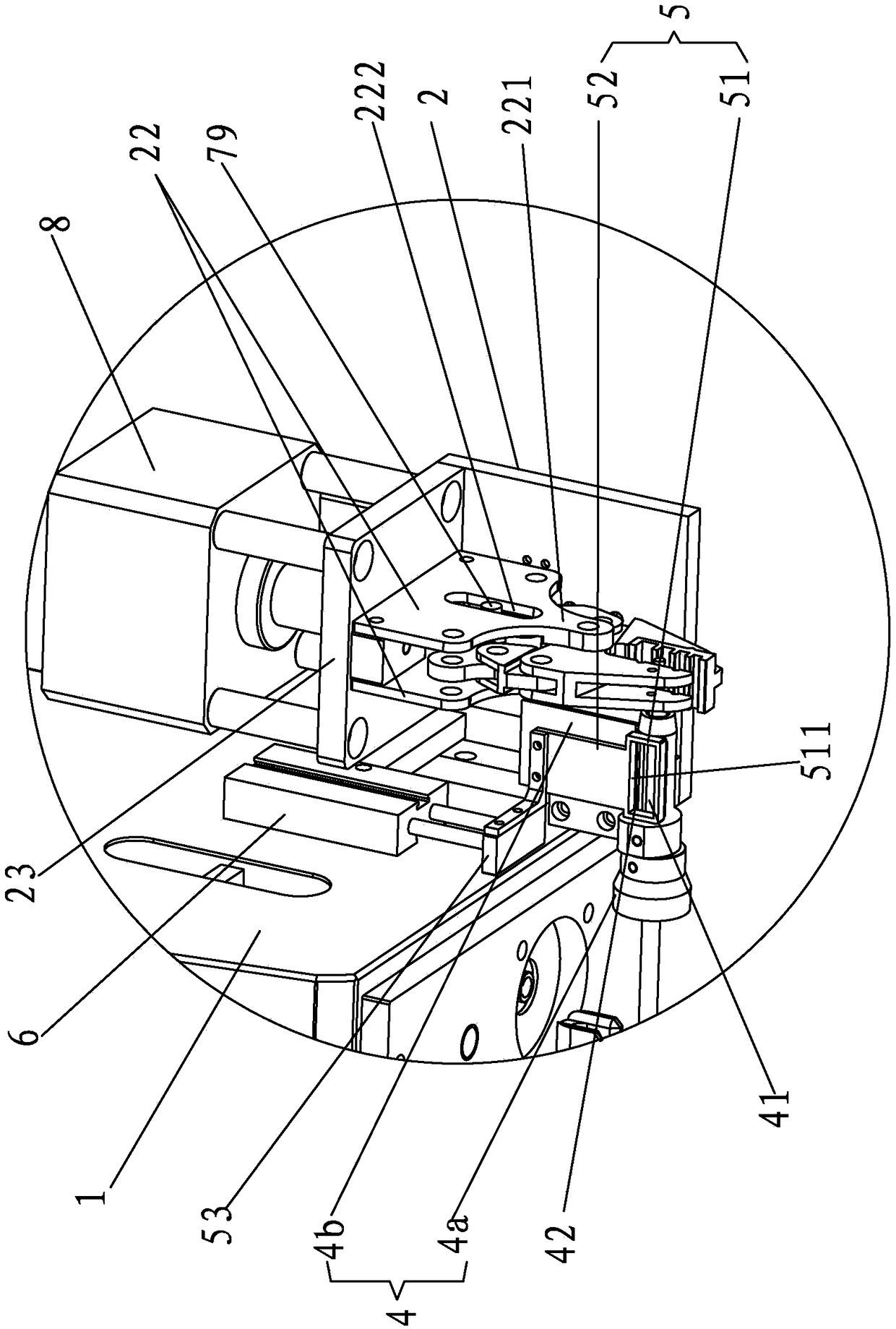

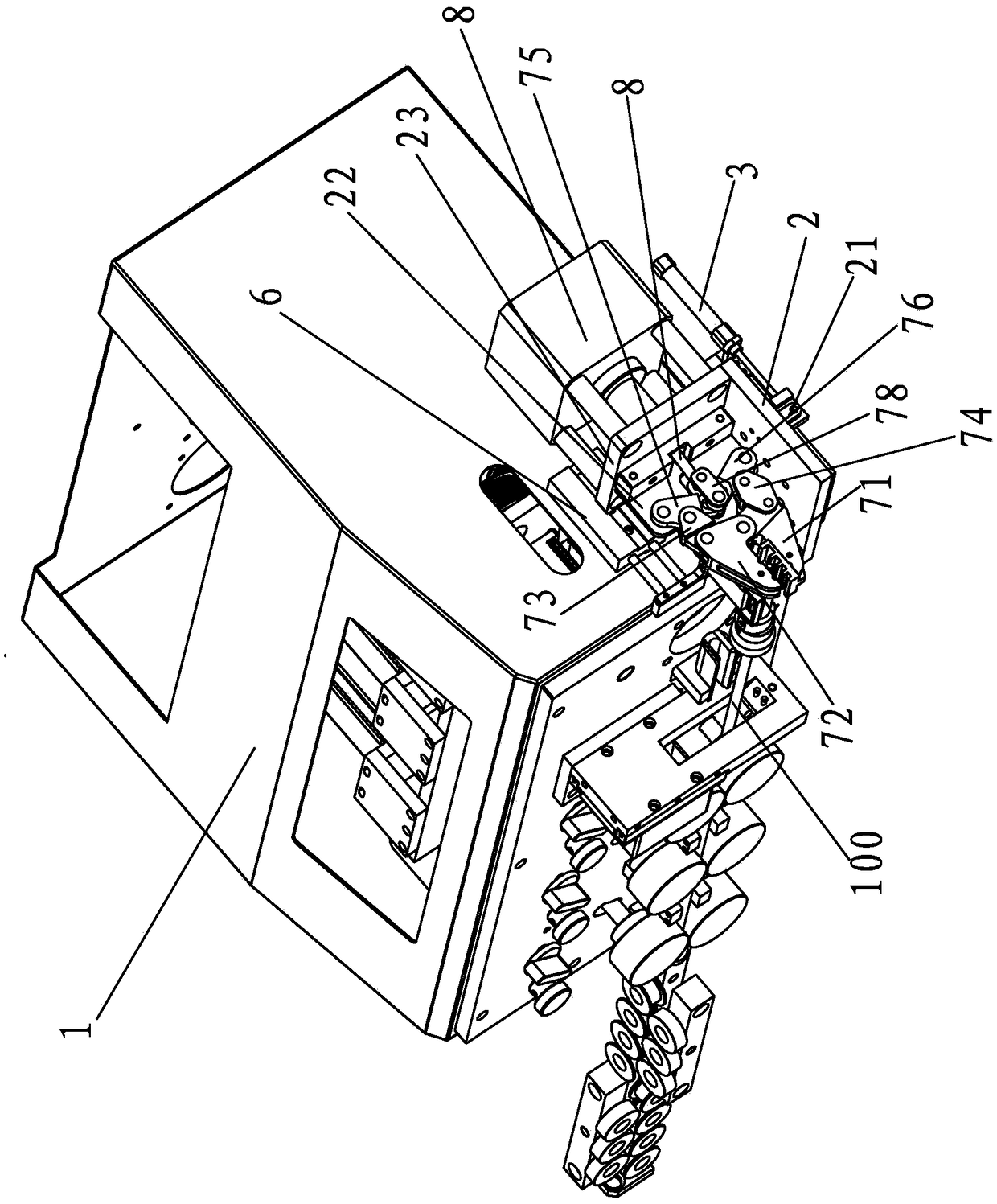

[0020] A wire stripping machine integrating stripping, bending and capping of the present invention, such as Figure 1-4As shown, the wire stripping machine body 1 is included, and the wire stripping machine body 1 adopts a wire stripping machine integrating wire stripping and bending, as disclosed by the State Intellectual Property Office on December 16, 2015, and the announcement number is CN204885797U A wire stripping machine that integrates stripping and bending.

[0021] The innovation of the present invention is: the stripping machine body 1 also has a plastic decorative cap installation mechanism for installing the plastic decorative cap, specifically: the cable 100 enters the wire direction on the stripping machine body 1 from left to In the right direction, the right side wall of the wire stripping machine body 1 is provided with a sliding seat 2 that can slide back and forth. The first sliding drive device that drives the sliding seat 2 to slide forward and backward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com