Sowing and fertilizing integrated machine for wheat

An all-in-one machine, wheat technology, applied in the directions of planter parts, sowing, fertilizer and planting equipment, etc., can solve the problems of complex procedures, low efficiency, time-consuming and laborious, and achieve the effect of alleviating bumps, shortening the planting process, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

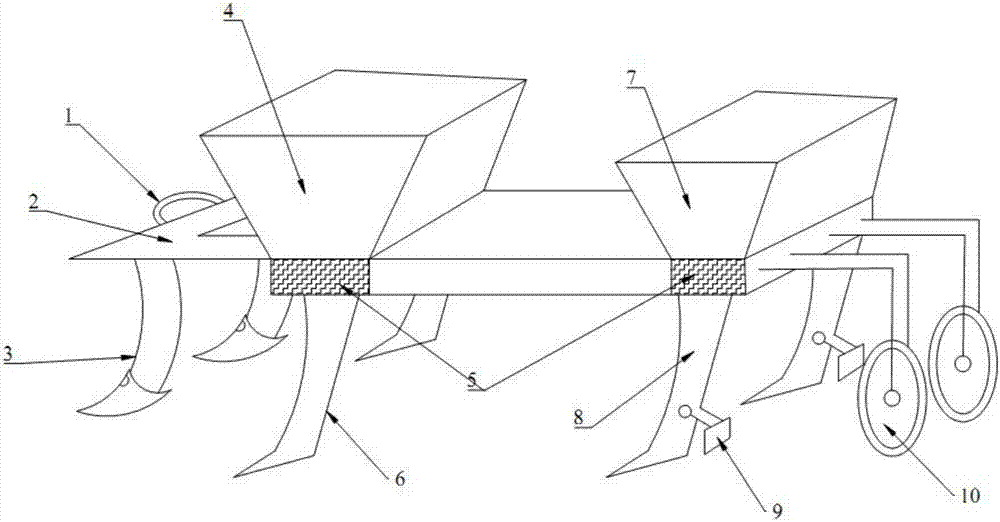

[0015] like figure 1 Shown: a wheat sowing and fertilizing integrated machine, its structure includes: connecting frame, support frame, furrow plow, fertilizer box, spring, lower fertilizer pipe, seed box, lower seed pipe, scraper, roller; connecting frame is The ring semicircle is welded on one end of the support frame, the support frame is a rectangular frame, the left and right sides of the lower front end of the support frame are welded with furrow plows, and the upper front end of the support frame is fixed with a fertilizer box by bolts. The fertilizer box communicates with the lower fertilizer pipe through a spring. Above the support frame, a seed box is installed on the rear side of the fertilizer box through bolts. The lower end of the seed box communicates with the lower seed pipe through a spring, and the rear end of the lower seed pipe is welded. There is a soil scraper, and rollers are installed on the left and right sides of the lower end of the support frame; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com