Rapid adjustment structure for conducting longitudinal cutting-apart and embossing molding on air conditioner fin mold

A technology for air-conditioning fins and adjusting structures, which is applied in the field of air-conditioning fin die slitting and embossing forming and rapid adjusting structures, can solve the problem of wasting time for operators, etc., and achieves easy die adjustment, die adjustment operation, and no professional skills desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

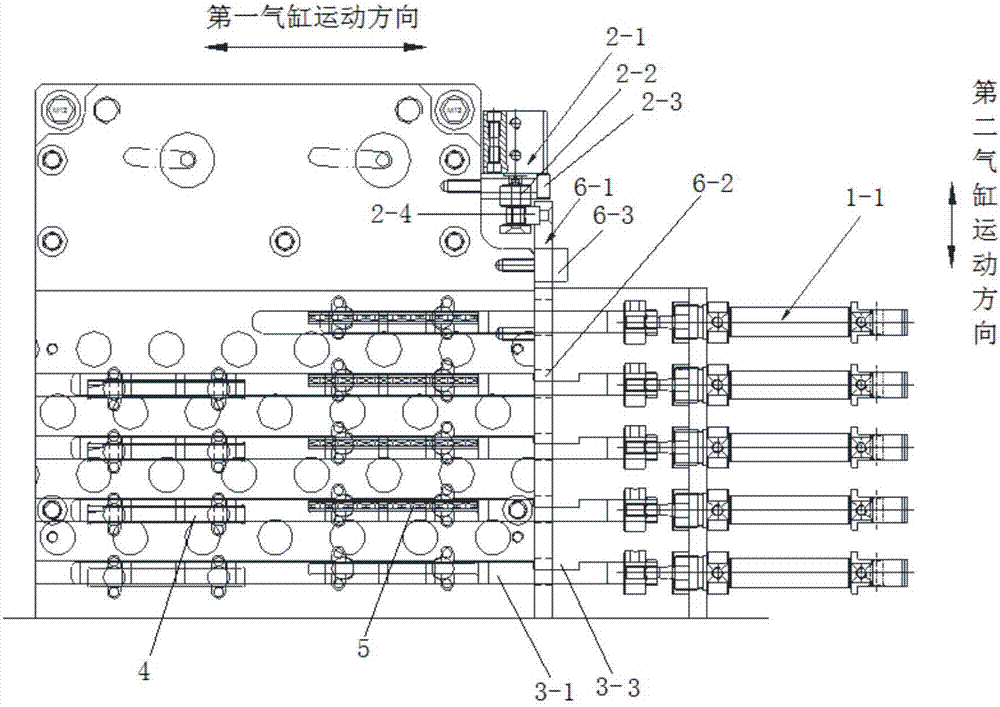

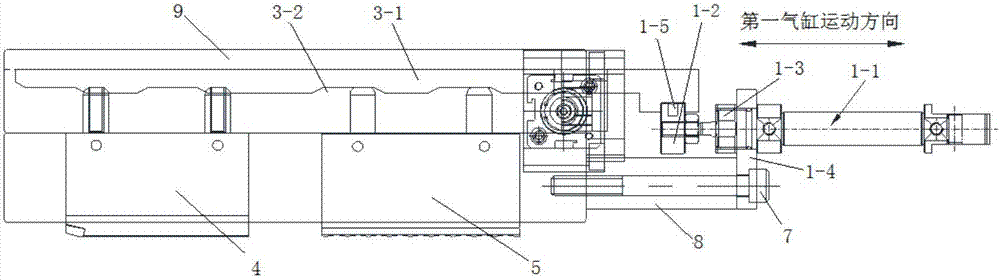

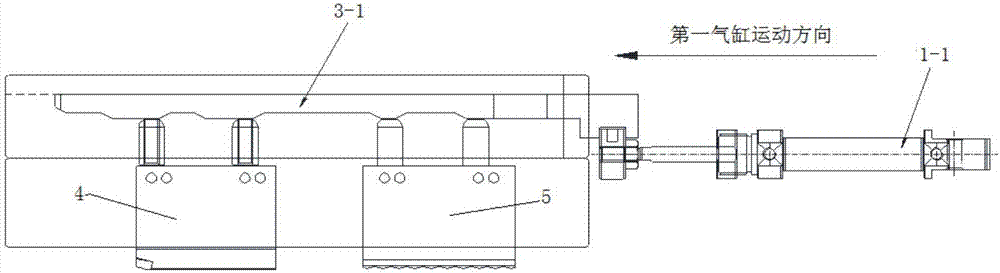

[0023] As shown in Figure-6, a quick adjustment structure for slitting, cutting and embossing forming of air-conditioning fin molds, including the first cylinder assembly, the second cylinder assembly, the drawing bar 3-1, the straight knife assembly 4, and the flower knife assembly 5 . Limiting column 6-1, the first cylinder assembly is fixed on the first cylinder fixing plate 1-4 through a nut 1-3, and the first cylinder fixing plate 1-4 passes through the first limiting block through screws 8 is fixed on the upper knife fixing plate 9, the first limit block 8 is set on the upper knife fixing plate 9 and the first cylinder fixing plate 1-4, and the first cylinder assembly is buckled with the drawing bar 3-1 connected, the straight knife assembly 4 and the flower knife assembly 5 are arranged on the upper knife fixing plate 9, and the second cylinder assembly is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com