Method for manufacturing printed article

A technology of printed matter and lithographic offset printing, which is applied in the field of manufacturing printed matter, can solve problems such as undesired extrusion of edges and damage to the appearance of printed products, and achieve low cost and avoid the effect of extrusion of edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

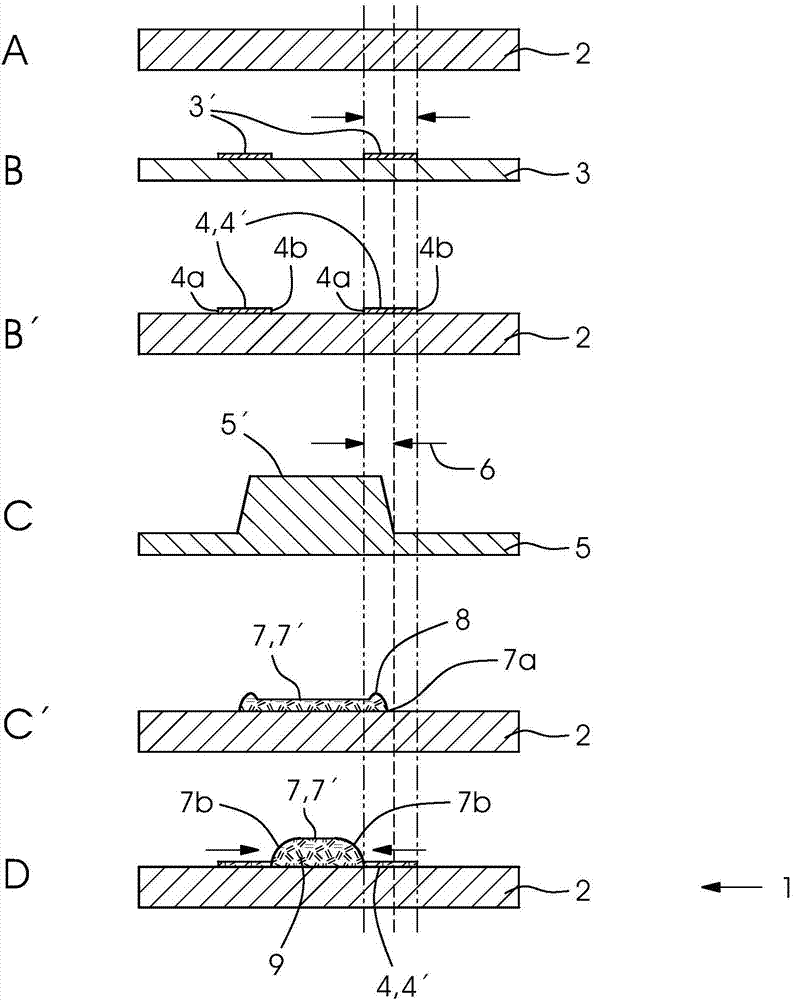

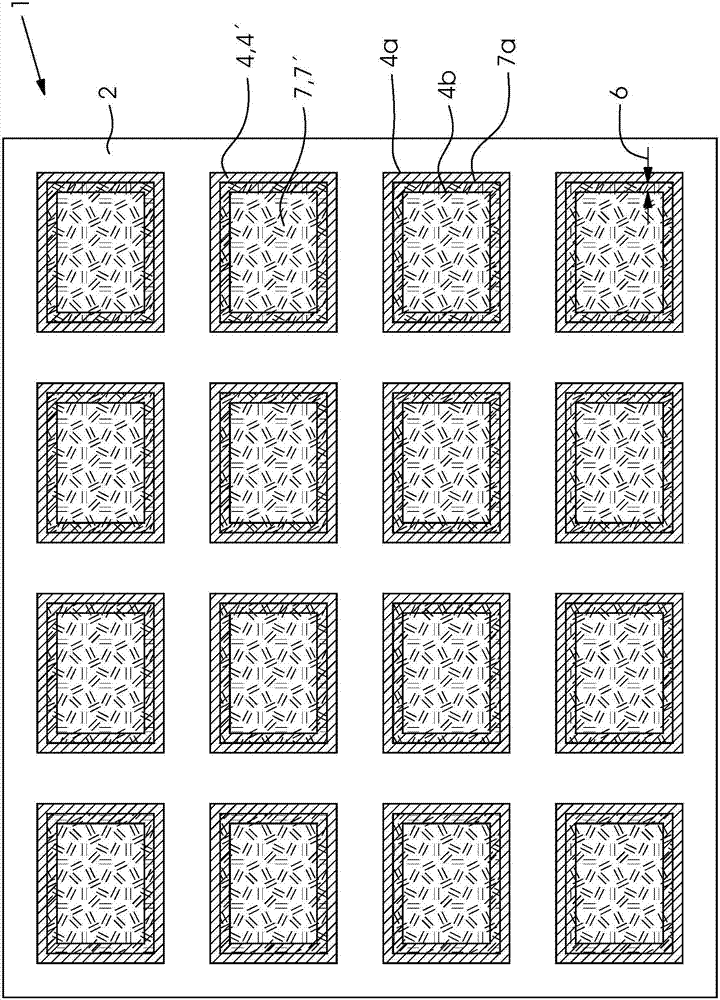

[0027] figure 1 The sequence of a preferred embodiment of the method according to the invention is shown step by step.

[0028] First, in method step A, a substrate 2 for the subsequent printed product 1 is provided. The provision can take place as follows: The substrate is guided from a printing material feeder to a first printing unit of the printing press. The substrate can be, for example, a paper, cardboard or foil sheet or also a web material.

[0029] In method step B, a first printing form 3 is provided, in particular an offset printing form. The printing form can be arranged, for example, on a printing form cylinder of the first printing unit. The printing plate has an area 3 ′ which guides the first printing liquid 4 . These areas can be generated, for example, by imaging the printing plate. The first printing liquid can be applied to the printing plate by means of the application device. Finally, the printing plate 3 comes into contact with the substrate 2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com