Twisting-resisting and anti-deformation power cable

A power cable, anti-deformation technology, applied to power cables, power cables with shielding layer/conductive layer, insulated cables, etc., can solve problems such as power cable breakage, insulation layer performance change, conductor temperature rise, etc., to achieve extended Effects of service life, maintaining straightness, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

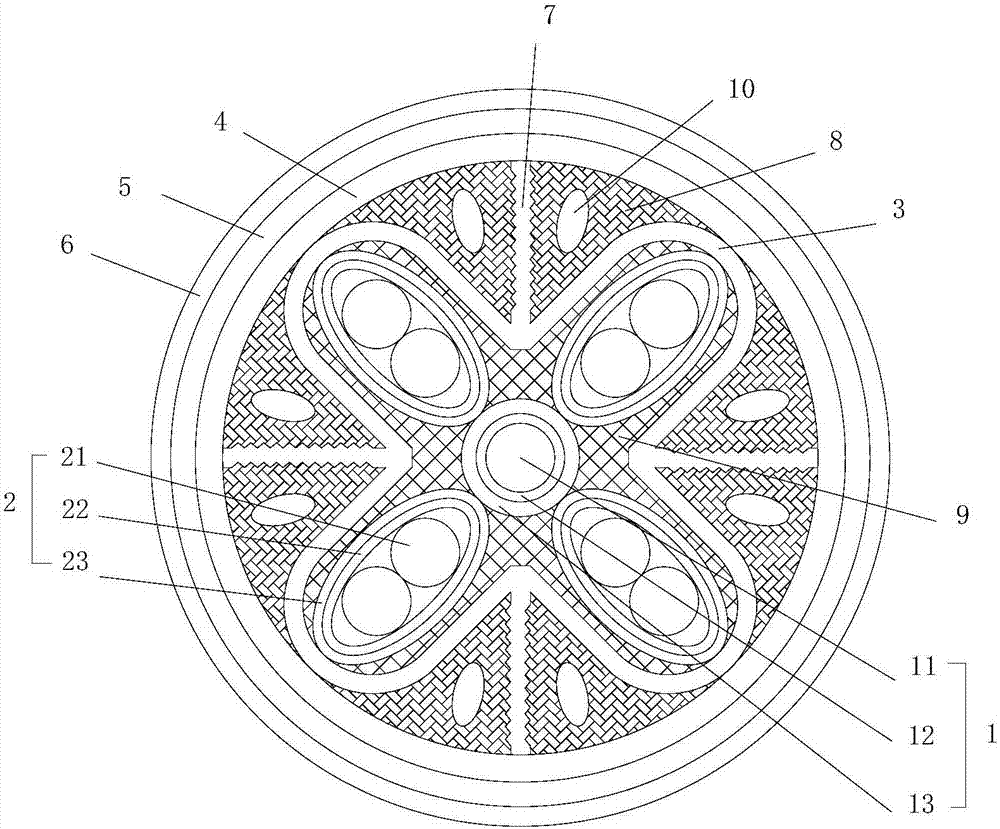

[0020] refer to figure 1 , the present invention proposes a twist-resistant and anti-deformation power cable, including a central conductor 1, a plurality of outer conductors 2 and an elastic protection tube 3, wherein:

[0021] The elastic protection tube 3 is made of polyurethane material, the center wire 1 and the four outer wires 2 are all arranged in the elastic protection tube 3, and the gap between the center wire 1, the four outer wires 2 and the elastic protection tube 3 is filled with Refractory materials9.

[0022] The central conductor 1 has a circular cross-section, the outer conductor 2 has an elliptical cross-section, and the central conductor 1 includes a central conductor 11, a central insulating layer 12 wrapped outside the central conductor 11, and a central shielding layer 13 wrapped outside the central insulating layer 12. The shielding layer 13 is formed by loosely winding copper wires, and the outer shielding layer 23 is formed by overlapping and wrappi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com