Steel-concrete-composite-bridge durability improving construction and construction method

A construction method and durability technology, applied in bridges, bridge materials, bridge construction, etc., to reduce cracks, reduce crack development, and reduce the possibility of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

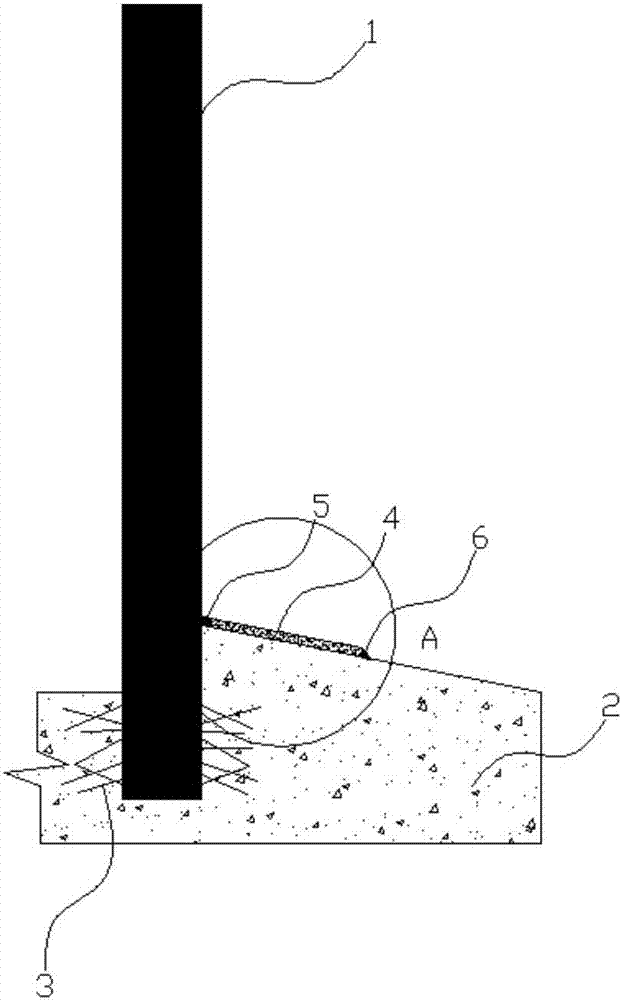

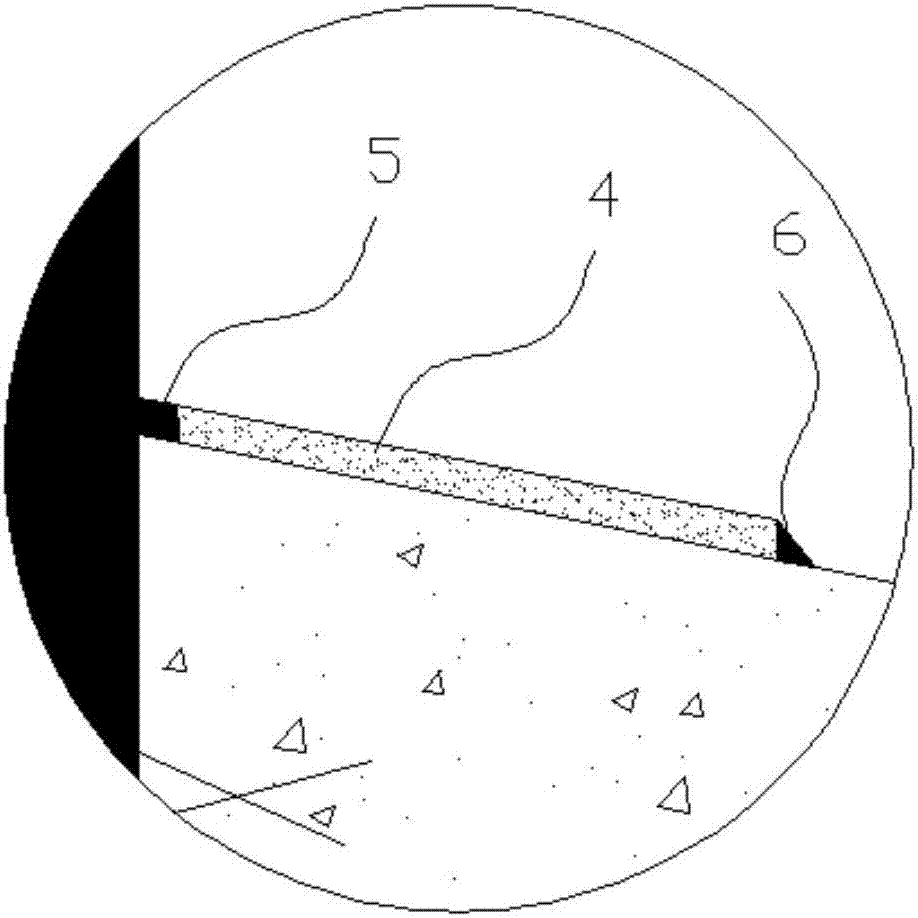

[0026] Such as figure 1 Shown is a schematic diagram of the durability improvement structure of the steel-concrete composite bridge of the present invention, including steel 1 , reinforced concrete 2 , steel needle 3 , waterproof brick 4 , rubber 5 and mortar 6 .

[0027] Reinforced concrete 2 is poured on the bottom of the outer surface of steel 1, and a plurality of steel needles 3 are set at the position where steel 1 and reinforced concrete 2 are connected. The specific number of steel needles 3 is not limited, and can be selected according to construction requirements and conditions.

[0028] In a preferred manner, the steel needles 3 are divided into two groups, and the two groups of steel needles 3 are arranged at an angle of 30 degrees to each other, and are respectively welded to the outer surface of the steel material 1 .

[0029] In another preferred manner, the steel needles 3 are divided into two groups, and the two groups of steel needles 3 are arranged at an ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com