Sawtooth-shaped silencing device

A sound-absorbing device, saw-tooth-shaped technology, applied to parts of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., can solve problems such as large noise, increased noise, and ineffective effects , to achieve the effect of convenient installation and disassembly, prevention of dust clogging, unique and novel mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The content of the present invention will be described in further detail below with reference to the accompanying drawings.

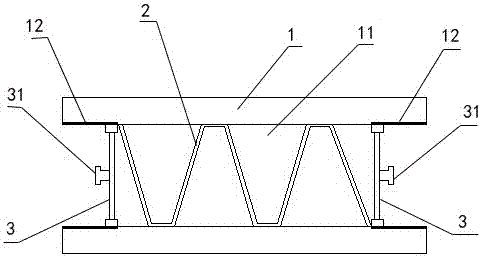

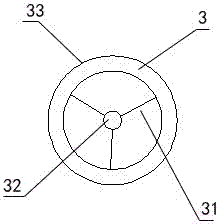

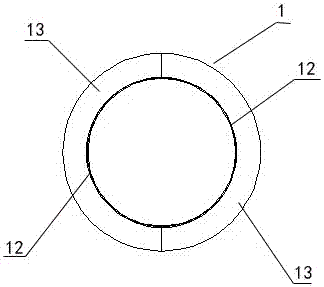

[0015] like figure 1 As shown, a zigzag muffler device includes a fixed cylinder 1 , a positioning ring 3 and a muffler cotton 2 . Both ends of the fixed cylinder 1 are open, and a muffler cavity 11 is arranged inside. like image 3 As shown, the fixed cylinder 1 includes two semi-circular bodies 13 with a semi-circular cross-section, the two semi-circular bodies 13 are connected to form a cylindrical structure, and the inner sides of both ends of the two semi-circular bodies 13 are provided with mutually matching internal threads 12. Two positioning rings 3 are provided, and external threads 33 are provided on the outside of the positioning rings 3 . The positioning ring 3 is mounted on both ends of the semi-circular body 13 through the external thread 33 and the internal thread 12 . The muffler cotton 2 is installed in the muffler cavity 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com