Automatic firework barrel packaging machine

A technology for automatic packaging machines and fireworks canisters, which can be applied to fireworks, offensive equipment, weapon types, etc., and can solve problems such as manual manipulation of fireworks packaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

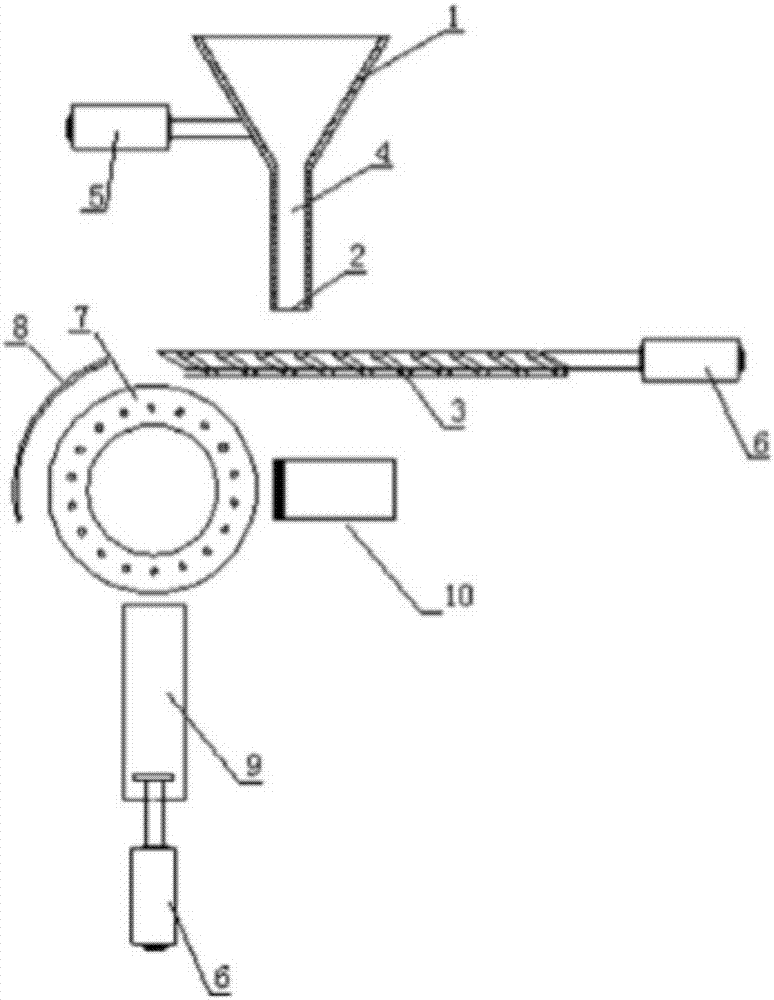

[0017] Such as figure 1 and figure 2 As shown, the automatic packaging machine for fireworks tubes in a preferred embodiment of the present invention includes a paper feeding mechanism 9 for wrapping paper, a tube feeding mechanism for fireworks tubes, and a drum-type sticker packaging mechanism 7, wherein the drum-feeding mechanism is located at the end of the drum-type sticker packaging mechanism 7 In the upper part, the paper feeding mechanism 9 is located at the lower part of the drum type sticker packaging machine 7. The paper feeding mechanism 9 is connected with an electric paper feeder 6. When the paper is reduced, the pallet on the upper part of the electric paper feeder 6 moves upward to allow the paper to The distance to the roller remains constant. The tube delivery mechanism includes a storage bin 1 with a firework tube outlet at the bottom and a fireworks tube receiving and conveying mechanism located under the storage bin 1 . The firework tube receiving and c...

Embodiment 2

[0022] Such as figure 1 and figure 2 As shown, the difference from the first embodiment is that the conveyor belt or the conveyor plate 3 is a fixed flat plate, which becomes the carrier plate 3 . Fireworks tube outlet 2 is located close to the position directly above the drum-type sticker packaging mechanism 7, and the power device 6 of the fireworks tube receiving and transmitting mechanism becomes a push mechanism, and its front end is provided with a push rod. , pushed forward by the push rod to realize timing and quantitative feeding.

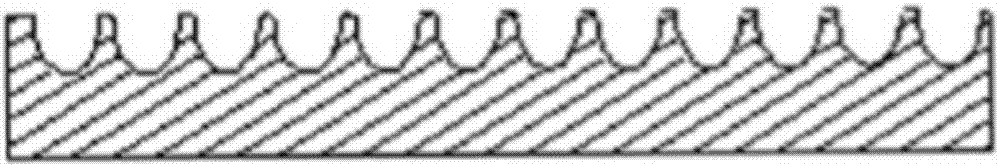

[0023] In order to help stabilize the posture of the fireworks tube, the outlet of the fireworks tube is located at 2 and one side of the pushing mechanism 6 is formed as a comb, and the other side is formed as an opening. The front part of the pushing mechanism 6 has several comb-shaped push rods corresponding to the comb-shaped outlet 2 , and is located at the front end of the outlet 2 of the fireworks tube. This facilitates maintain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com