Steamed stuffed bun processing equipment

A kind of processing equipment and steamed bun technology, which is applied in the direction of dough forming and cutting equipment, horizontal installation tool mixing/kneading, dough mixer, etc., which can solve the problems of no handmade steamed stuffed buns, taste disadvantages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

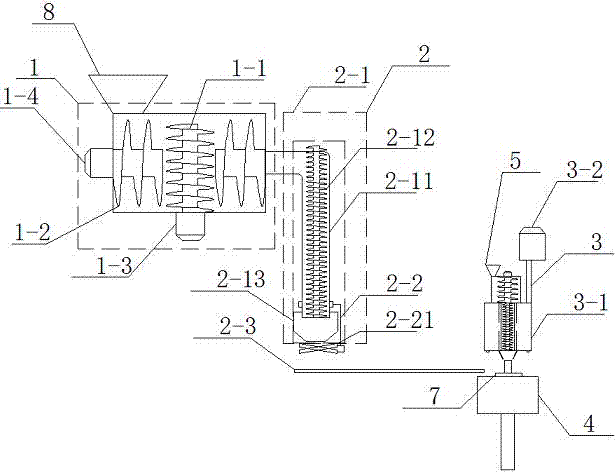

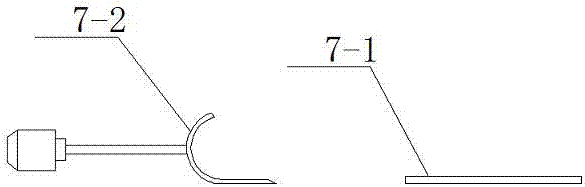

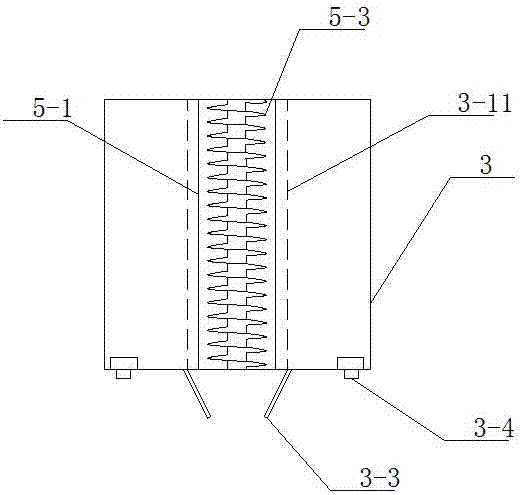

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] see as Figure 1-Figure 5 As shown, the technical solution adopted in this specific embodiment is: it comprises a dough kneading mechanism 1, a dough conveying mechanism 2, a dough skin pressing mechanism 3, a forming platform 4, a stuffing conveying mechanism 5, a forming mechanism 6, and a deriving mechanism 7; The dough kneading mechanism 1 is horizontally arranged, and a dough inlet 8 is arranged above one end; the kneading dough screw 1-1 and the dough feeding screw 1-2 are arranged in the kneading dough mechanism 1, and the kneading dough screw 1-1 is vertically arranged on the kneading The inner middle part of the dough mechanism 1 is driven by the dough kneading motor 1-3 located at the bottom of the dough kneading mechanism 1. Driven by the dough feeding motor 1-4 arranged on the side, under the joint action of the dough mixing screw 1-1 and the dough ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com