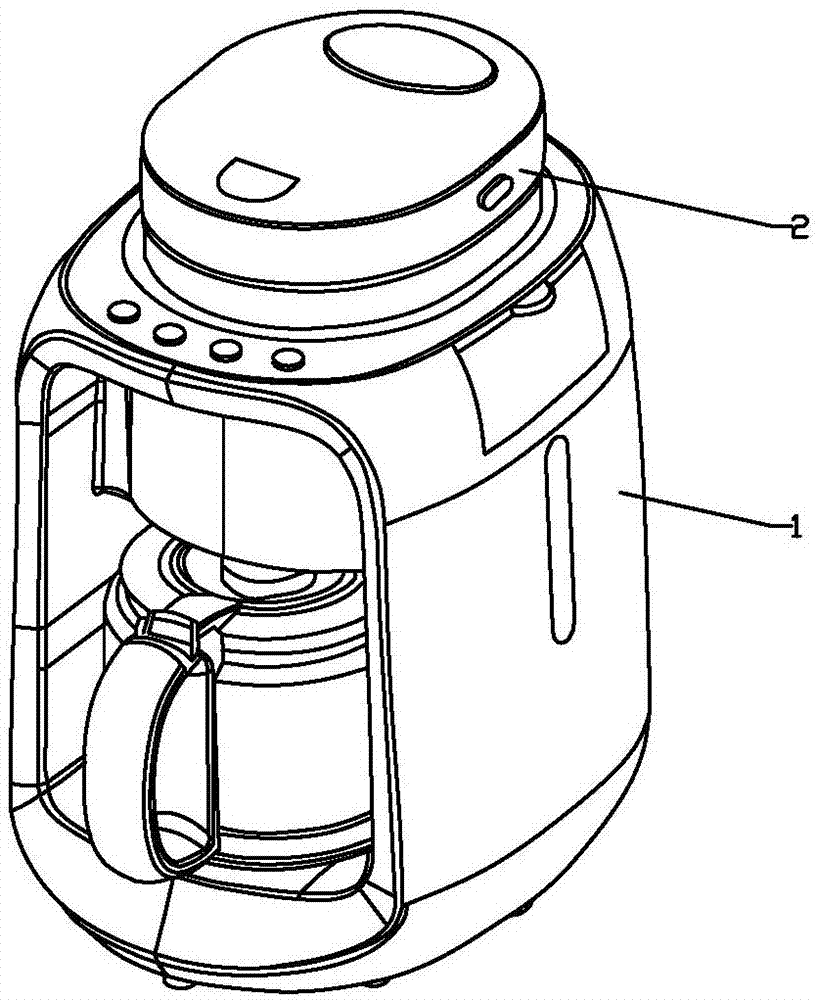

Disassemble and cleaning structure of automatic coffee machine

A coffee machine, automatic technology, applied in kitchen utensils, home utensils, beverage preparation devices, etc., can solve the problems of brewed coffee with a large difference in taste concentration, inability to easily remove residual powder, poor consumer experience, etc., and achieve better taste. Excellent, reliable performance, easy to split

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

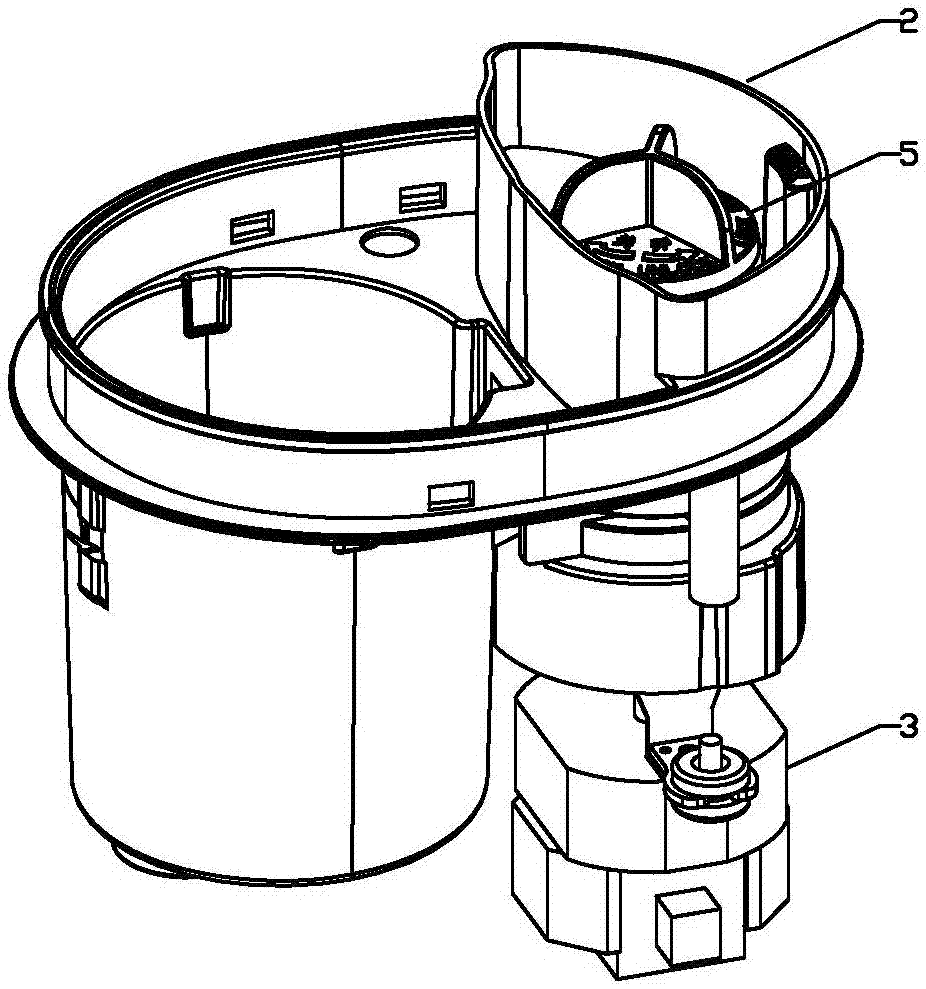

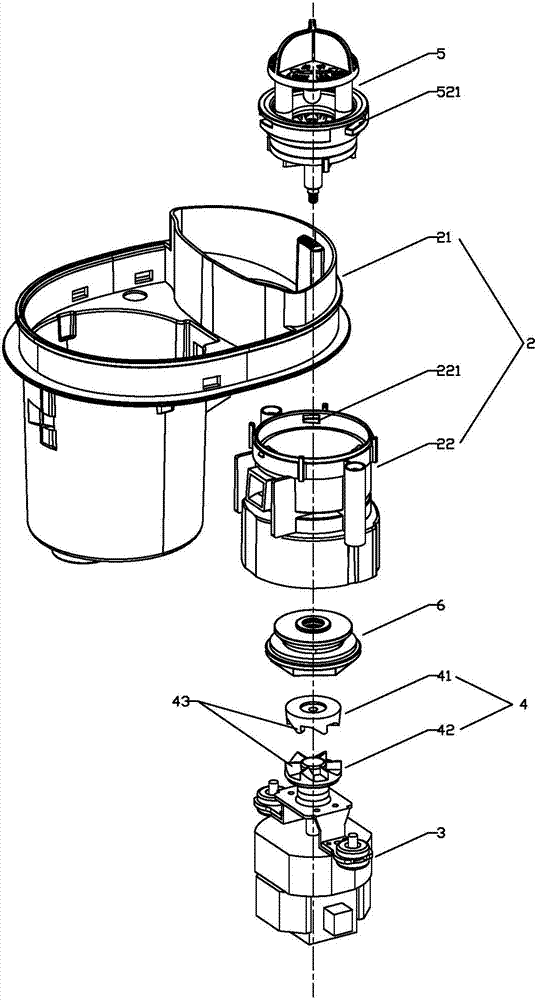

[0023] The present invention will be further described below in conjunction with accompanying drawing, according to Figure 1-Figure 4 As shown, the detachable and washable structure of the automatic coffee machine includes a main machine 1 and a bean grinding device 2, and the bean grinding device 2 is detachably inserted on the main machine 1 from top to bottom to realize mutual assembly; the main machine 1 is provided with a driving motor 3, The bean grinding device 2 includes a bean grinding shell detachably assembled on the main machine 1 and a grinding assembly arranged in the bean grinding shell; the bean grinding shell is provided with a bean grinding chamber a, and the grinding assembly is arranged in the bean grinding chamber a; A clutch 4 is arranged between the grinding assembly and the drive motor 3, and the clutch 4 includes an upper clutch part 41 that is connected to the grinding assembly and a lower clutch part 42 that is connected to the output shaft of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com