Thermal print head temperature control circuit and thermal printer

A thermal print head, temperature control technology, applied in printing and other directions, can solve the problems of protecting the print head, continuous large, incapable, etc., to achieve effective control, good printing experience, and avoid overheating damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

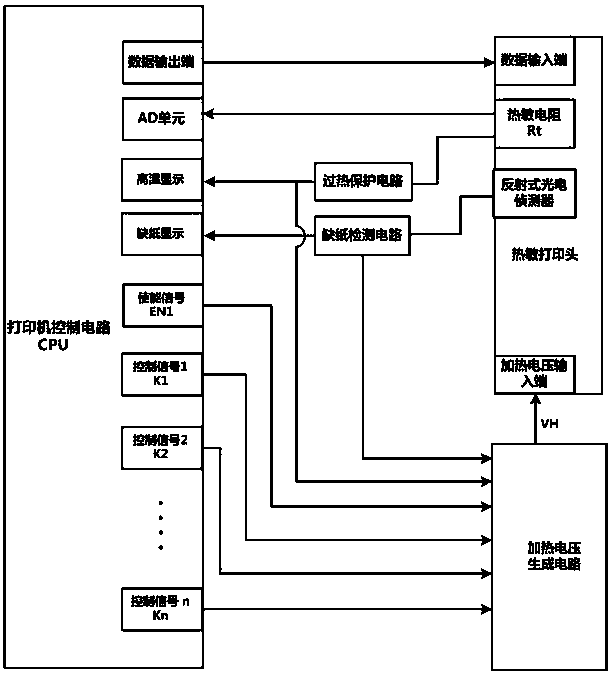

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

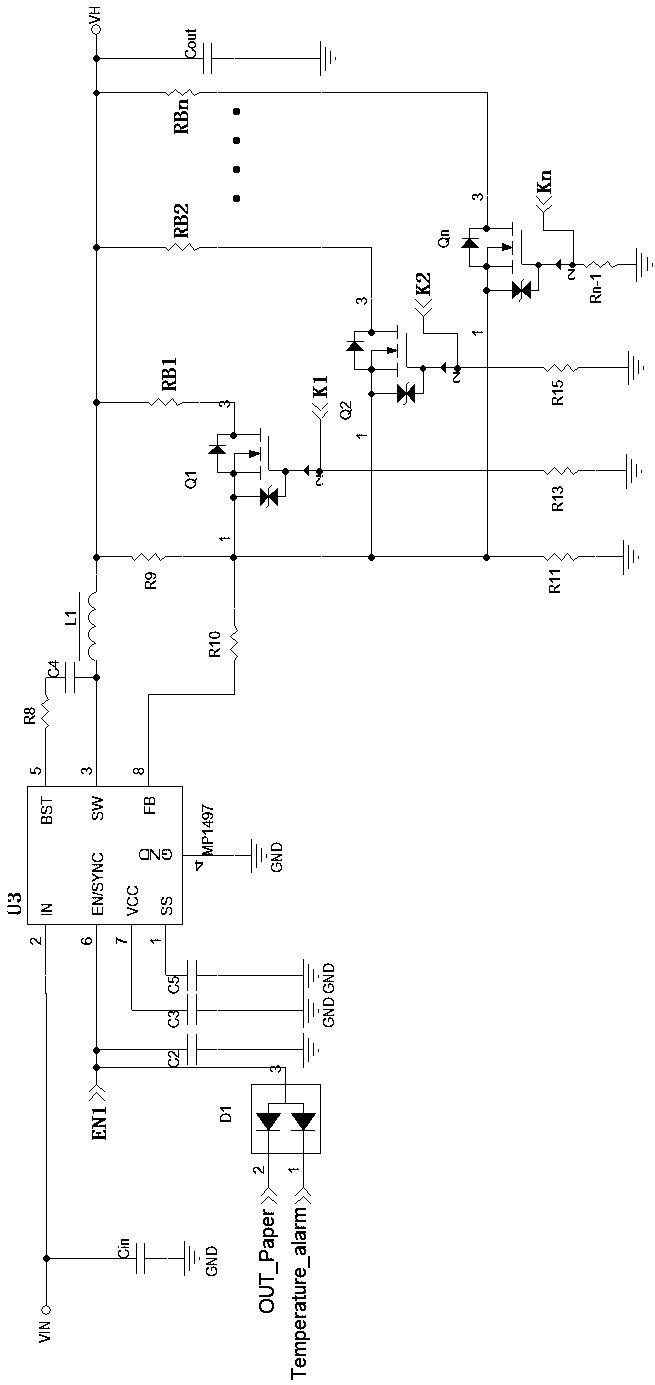

[0022] In order to effectively control the temperature of the thermal print head, the temperature control circuit of the thermal print head in this embodiment adopts the method of timely adjusting the heating voltage of the thermal print head according to the temperature change of the thermal print head, and then changing the current flow during the printing process. Overheating the heating current of the thermal print head, thereby effectively controlling the temperature rise of the print head and fundamentally protecting the design purpose of the thermal print head.

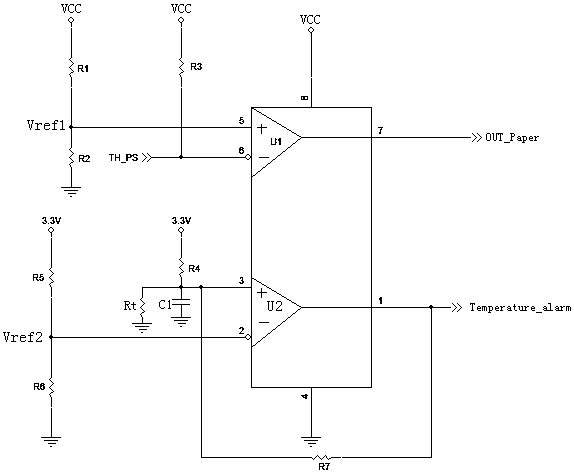

[0023] In order to enable the thermal printer to adaptively adjust the heating voltage applied to the thermal print head according to the temperature change of the thermal print head, this embodiment designs a temperature detection circuit in the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com