Tread contour fitting method capable of automatically extracting segmentation points

An automatic extraction and segmentation point technology, applied in image analysis, image data processing, instruments, etc., can solve problems such as serious wheel wear and decreased train safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

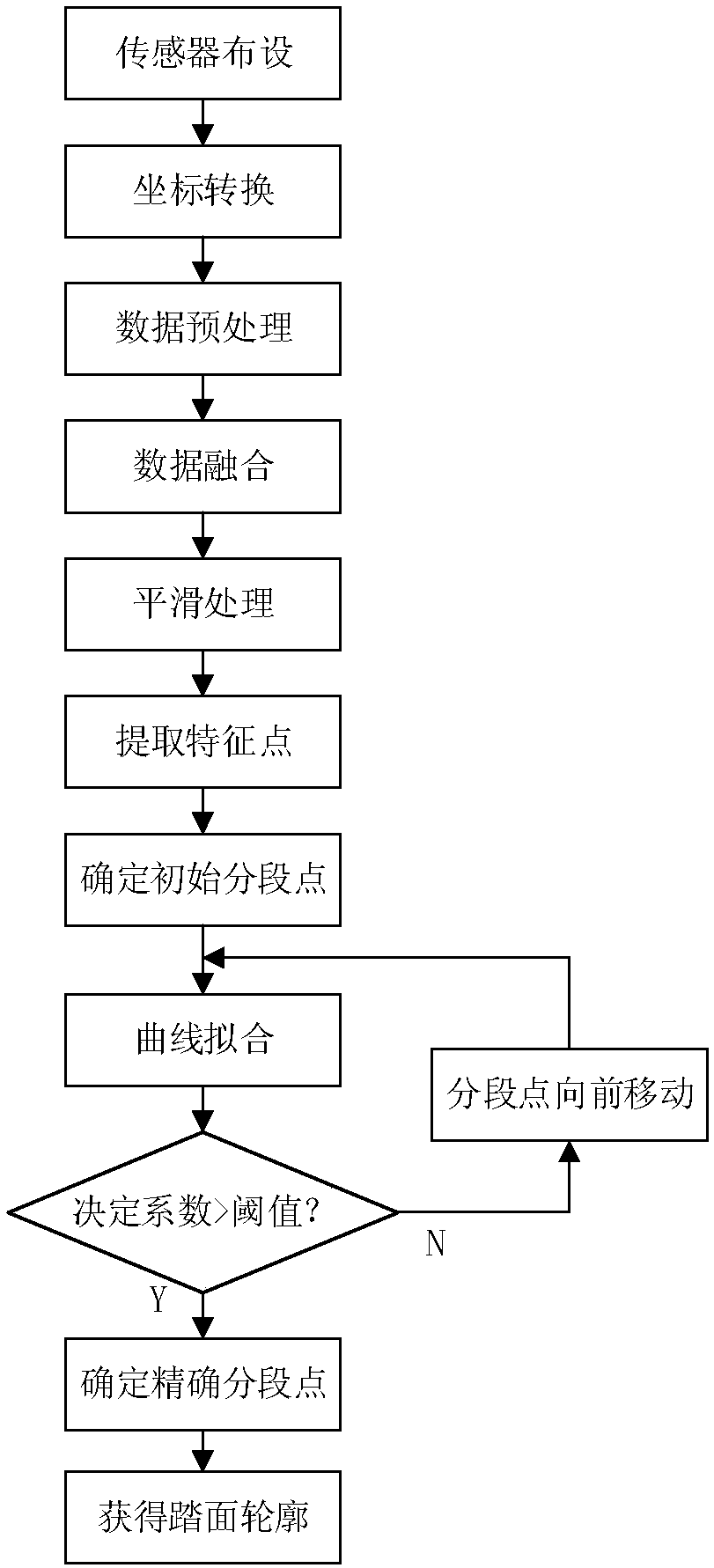

Method used

Image

Examples

Embodiment 1

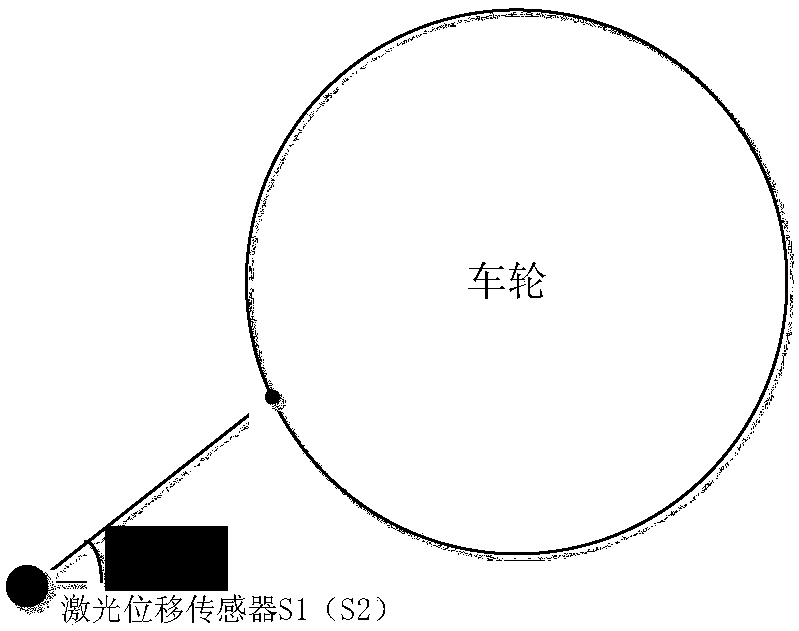

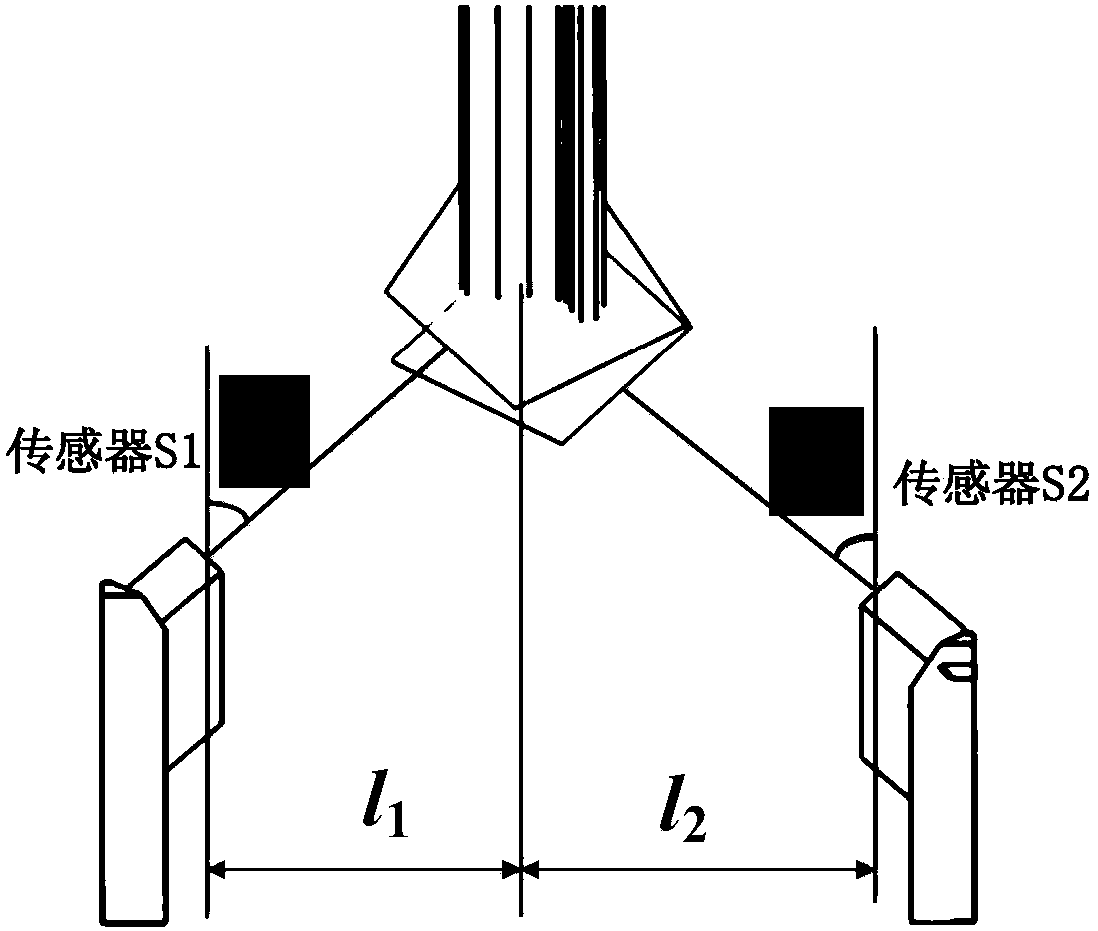

[0150] combine Figure 2~3 , the laser displacement sensors S1 and S2 are installed on the inner and outer sides of the track according to the mirror symmetrical method, and the angle between the sensors S1 and S2 and the vertical line is 42°~48°, then β 1 , β 2 α 1 、α 2 is 42°~48°, and the vertical installation distances between sensors S1, S2 and the track are both 300mm, then l 1 , l 2 is 300mm. Take β 1 = β 2 = 45°, α 1 = α 2 =45°, detect the passing wheels, and transform the coordinates of the collected data points according to the following formula.

[0151] u (1) =x 1 cos 45°+y 1 sin 45° v (1) =x 1 cos45°-y 1 sin 45°

[0152] u (2) =-x 2 sin 45°+y 2 cos 45° v (2) =x 2 sin 45°+y 2 cos 45°

[0153] Extract the data points of the tread profile and filter out the interference points for the transformed data. The specific process is as follows:

[0154] 1) Obtain the data points of the tread part

[0155] According to the data points after coordinate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com