A power converter control circuit capable of realizing controller parameter self-tuning

A power converter, parameter self-tuning technology, applied in output power conversion devices, electrical components, etc., can solve problems such as complex algorithms, poor output power quality, and poor adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

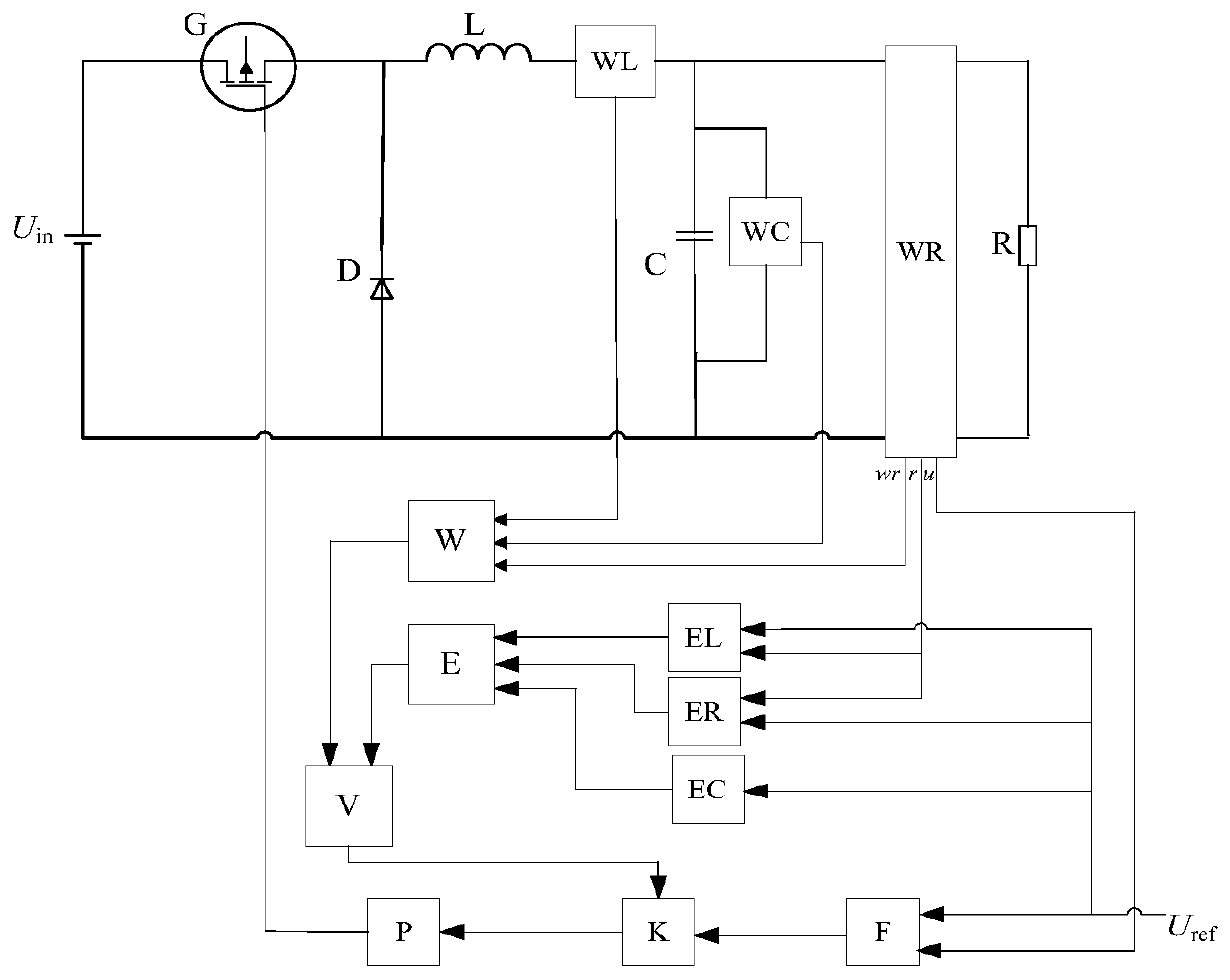

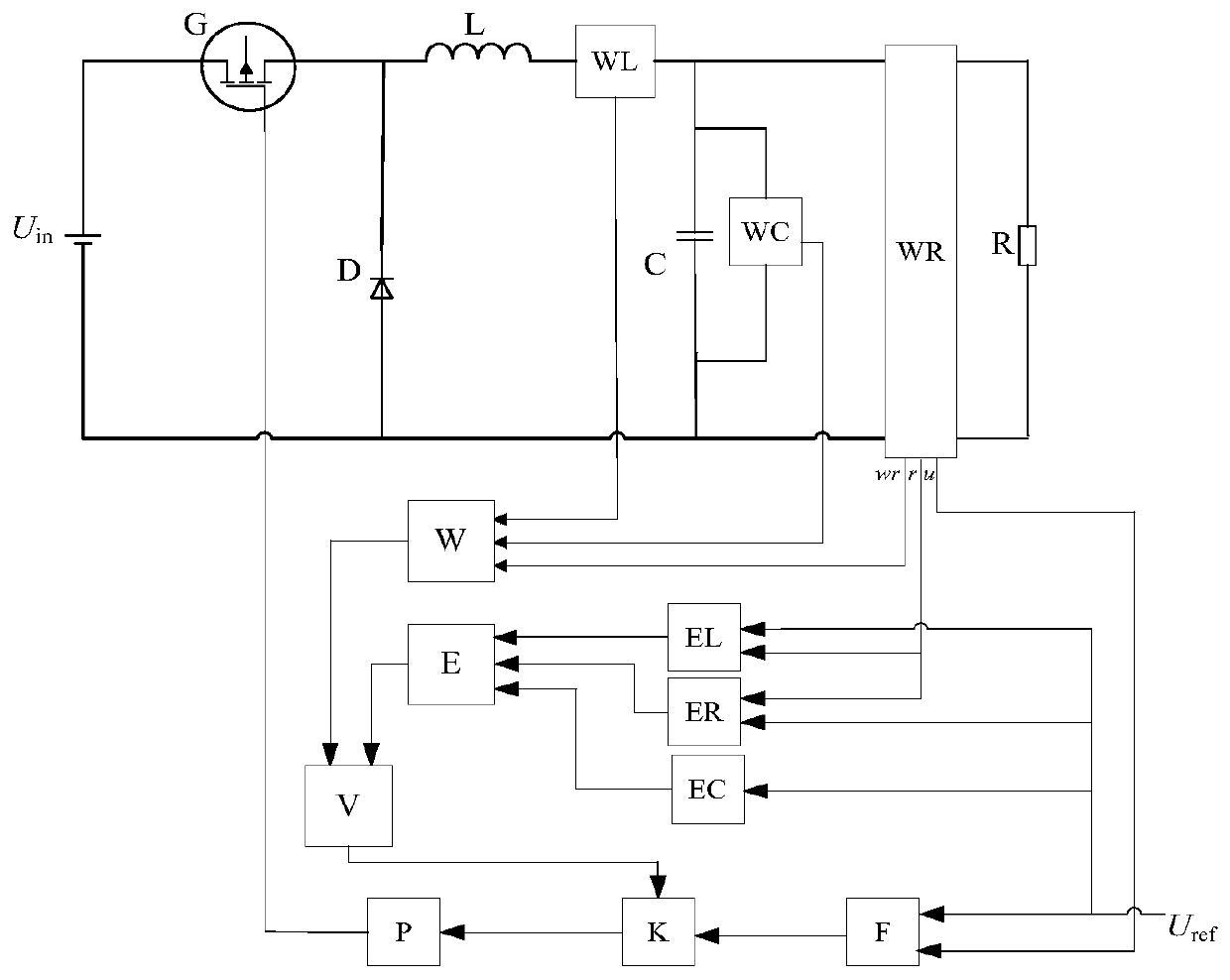

[0102] The power electronic device G, freewheeling diode D, filter inductor L, and filter capacitor C constitute the main circuit of the BUCK type DC-DC converter. The selection and parameter calculation of these devices are similar to the device selection and calculation of the existing BUCK type circuit. The parameter calculations are exactly the same. If it is a power converter of other forms, its main circuit component selection and parameter calculation are also completely consistent with the existing main circuit component selection and parameter calculation methods of this type of power converter.

[0103]The actual energy detection circuit WL of the inductor can be realized by using an existing circuit capable of real-time detection of energy and real-time data communication. For example, a single-chip microcomputer can be used to sample the inductor current through a Hall-type current sensor, and the The corresponding calculation of the current value can calculate the...

Embodiment 2

[0116] The actual energy detection circuit WL of the inductor can be realized by using an existing analog circuit capable of real-time detection of current and multiplication function. For example, the Hall-type current sensor can be used to sample the inductor current, and the multiplication circuit can be used to calculate the energy stored in the inductor, and the analog signal output by the multiplication circuit can be transmitted to other circuits. The design of the multiplication circuit is the same as that of the existing The design method of the multiplication circuit is the same.

[0117] The actual energy detection circuit WC of the capacitor can be realized by using an existing analog circuit capable of real-time detection of voltage and multiplication function. For example, a Hall-type voltage sensor can be used to sample the capacitor voltage, and a multiplication circuit can be used to calculate the energy stored in the capacitor, and the analog signal output by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com