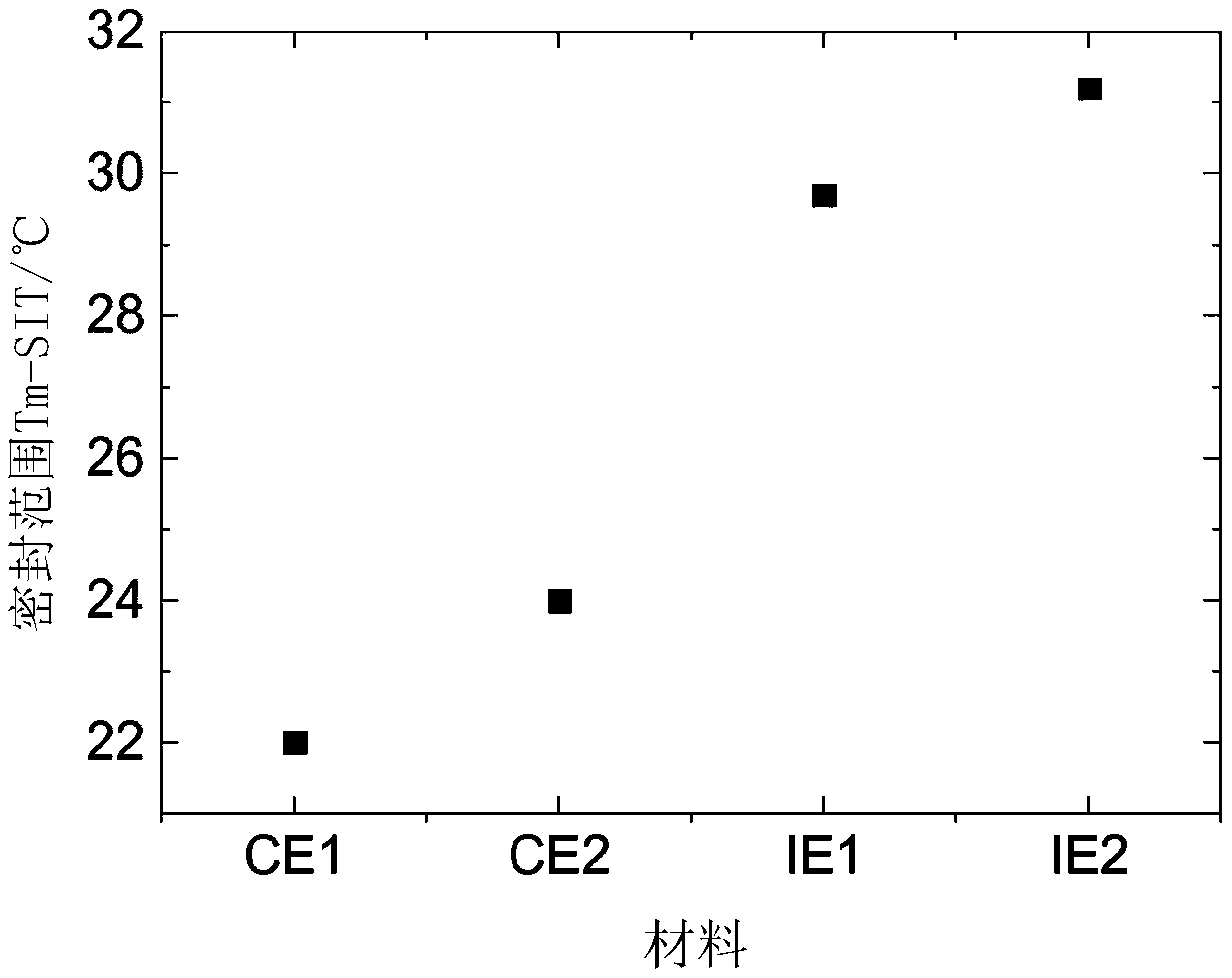

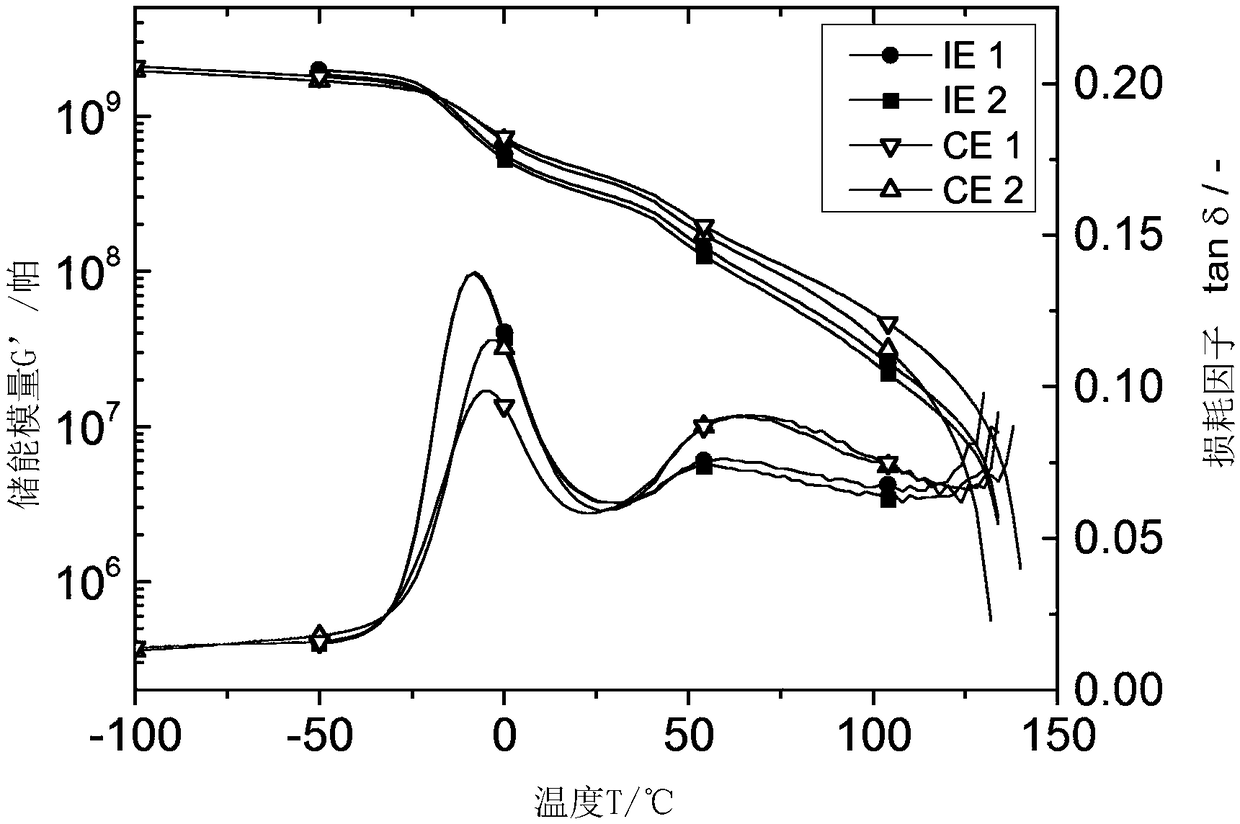

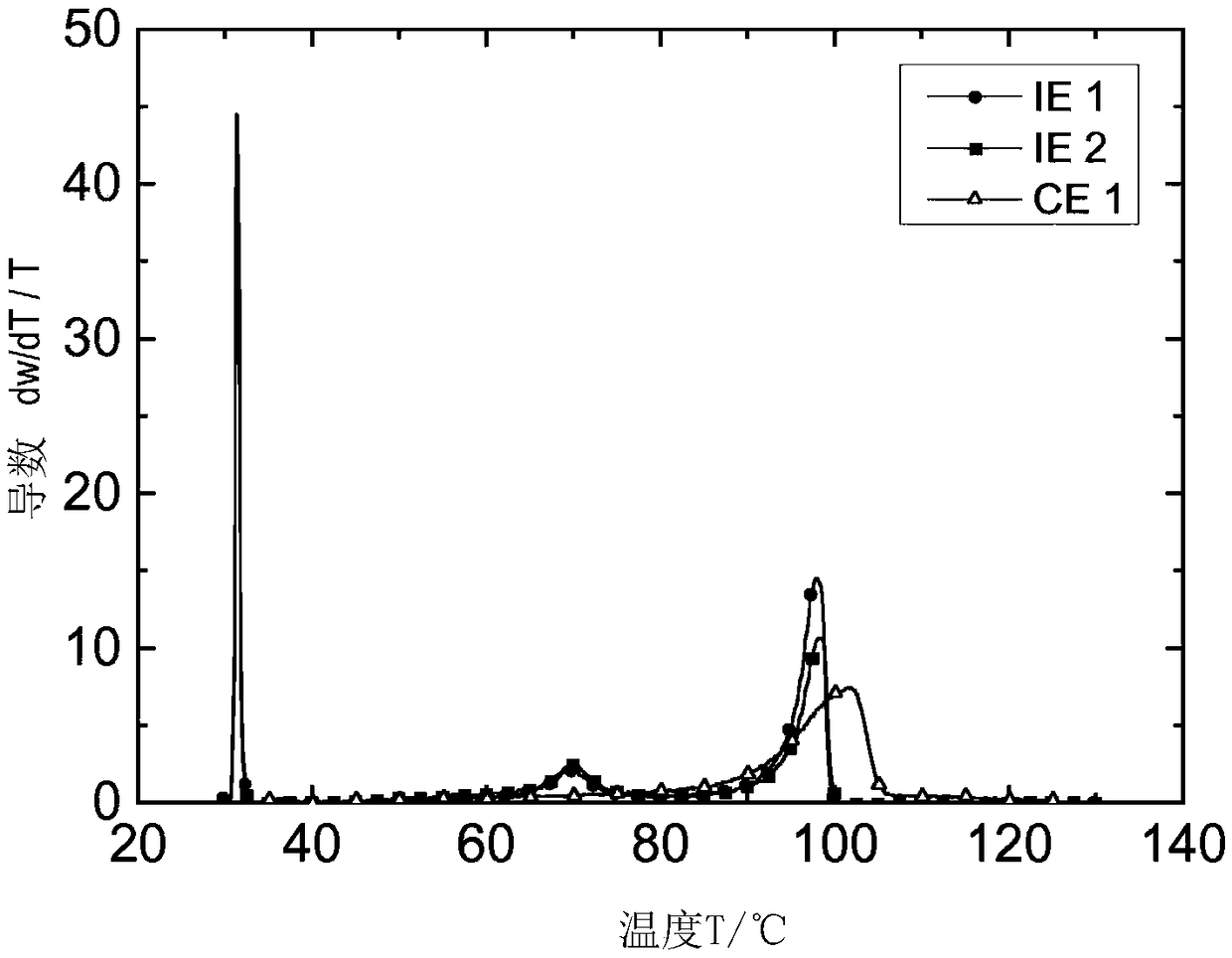

c2c3 random copolymer composition with improved balance between seal initiation temperature and melting point

A technology of random copolymer and composition, which is applied in the field of C2C3 random copolymer composition, which can solve the conflict between final performance and processing performance, and achieve the effects of good optical performance, low haze, and wide sealing window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0232] In order to minimize possible problems associated with high activity or bleeding, it is preferred to "prepolymerize" the catalyst before using it in a polymerization process. It must be noted in this regard that prepolymerization is part of the catalyst preparation process and is a step carried out after the formation of the solid catalyst. This catalyst prepolymerization step is not part of the actual polymerization setup, which may also include conventional method prepolymerization steps. After the catalyst prepolymerization step, a solid catalyst is obtained and used for polymerization.

[0233] Catalyst "prepolymerization" occurs after the solidification step of the liquid-liquid emulsification process described above. The prepolymerization is carried out by known methods described in the prior art, for example the methods described in WO 2010 / 052263, WO 2010 / 052260 or WO 2010 / 052264. Preferred embodiments of this aspect of the invention are described herein.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com