Carrying clamping grasping block special for aluminum alloy forged hub

A technology of aluminum alloy and wheel hub, which is applied in the field of special handling and gripping block for aluminum alloy forged wheel hub, which can solve the problems of damage, heavy weight, and the failure of the gripper block to meet the handling requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

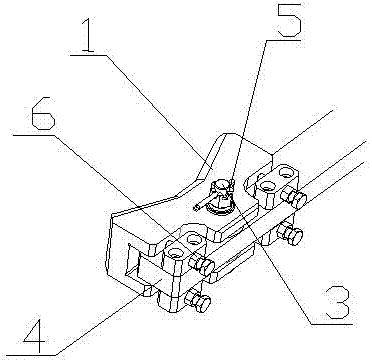

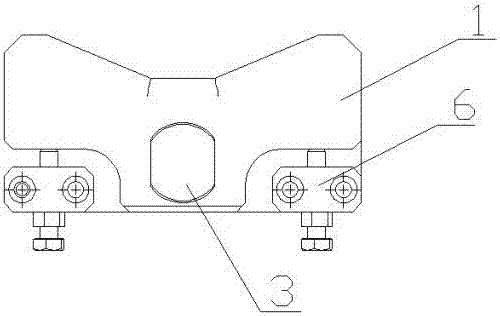

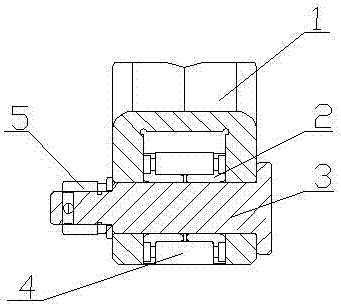

[0013] Depend on figure 1 , figure 2 , image 3 Known, a kind of aluminum alloy forged wheel hub special handling clamping block, is made up of V-shaped block 1, lubricating copper sleeve 2, fixed shaft 3, mechanical arm 4, lock nut 5, limit screw 6; Said V-shaped block 1 According to the shape of the product, there are V-shaped grooves in two directions, and the thickness of the clamping part is increased; the fixed shaft 3 passes through the installation hole of the V-shaped block 1 and the mechanical arm 4, and the lock nut 5 will fix the shaft 3 Locked on the mechanical arm 4, the V-shaped block 1 is fixed on the mechanical arm 4, and the V-shaped block 1 can rotate around the fixed axis 3. The lubricating copper sleeve 2 is installed between the V-shaped block 1, the mechanical arm 4 and the fixed shaft 3, and is used for lubrication between the V-shaped block 1 and the fixed shaft 3 when the V-shaped block 1 is active. The limit screw 6 is installed on the mechanical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com